Robot Customization with WAAM and Generative Design

Being involved with 3D printing for more than 15 years, I see the same dynamics over and over. Every time a new print technology is introduced and is received well, it takes the innovator considerable time to make an impact in the mainstream market. Unlike other technologies, many 3D printing products see significant growth once industries embrace it as mainstream.

Wire Arc Additive Manufacturing (WAAM) 3D metal printing has now reached large-scale metal objects. This new technology has quickly been recognized as a gamechanger. MX3D is a forward-thinking company that is introducing WAAM to several high-impact industries. It develops software that makes large-scale industrial 3D metal printers by connecting an off-the-shelf industrial robot and welding machine.

As most industries are unfamiliar with this new technology, we at MX3D see ourselves as technology evangelists. With the MX3D Robot Arm project, we show the potential for in-house spare part and heavy equipment production. Every metalworking workshop can be turned into a mini-casting company, reducing lead-time and increasing design freedom.

Why customize an industrial robot? Industry robotics is a growing industry with a large variety of application classes. Many OEMs offer a wide variety of models for specialized applications. But there is a need for even more individualization.

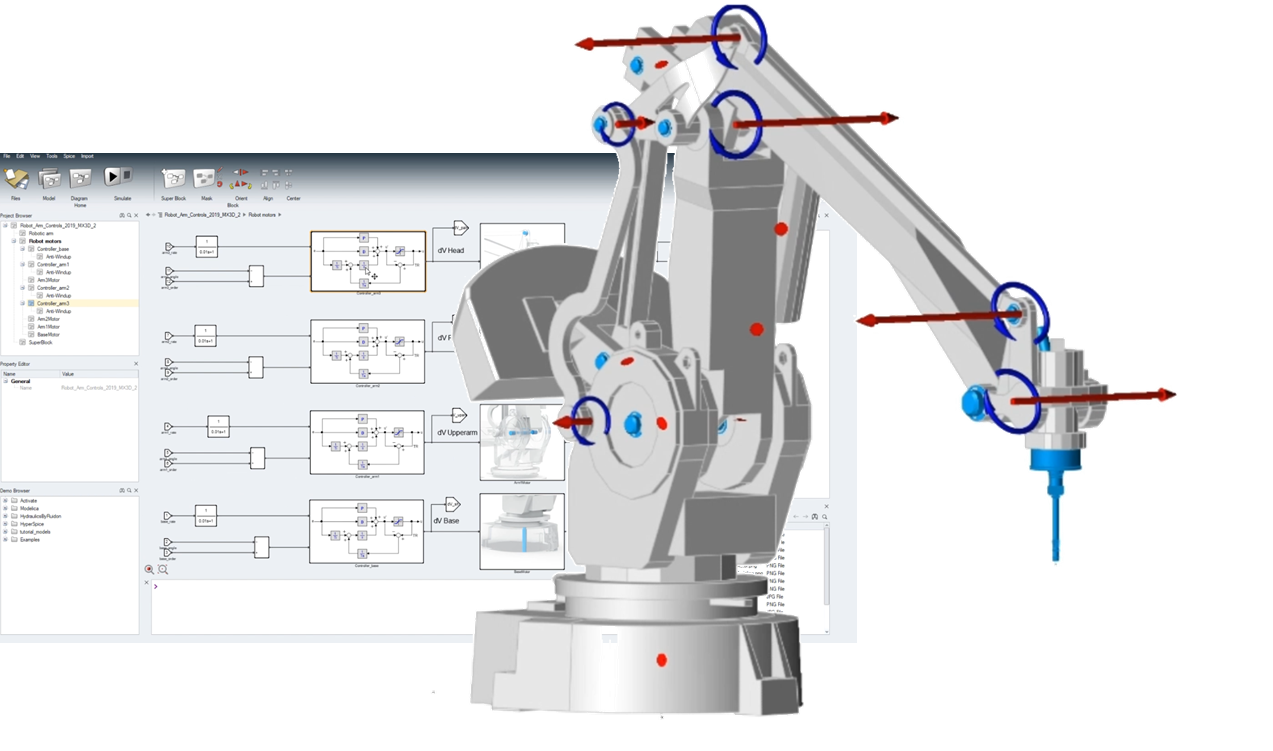

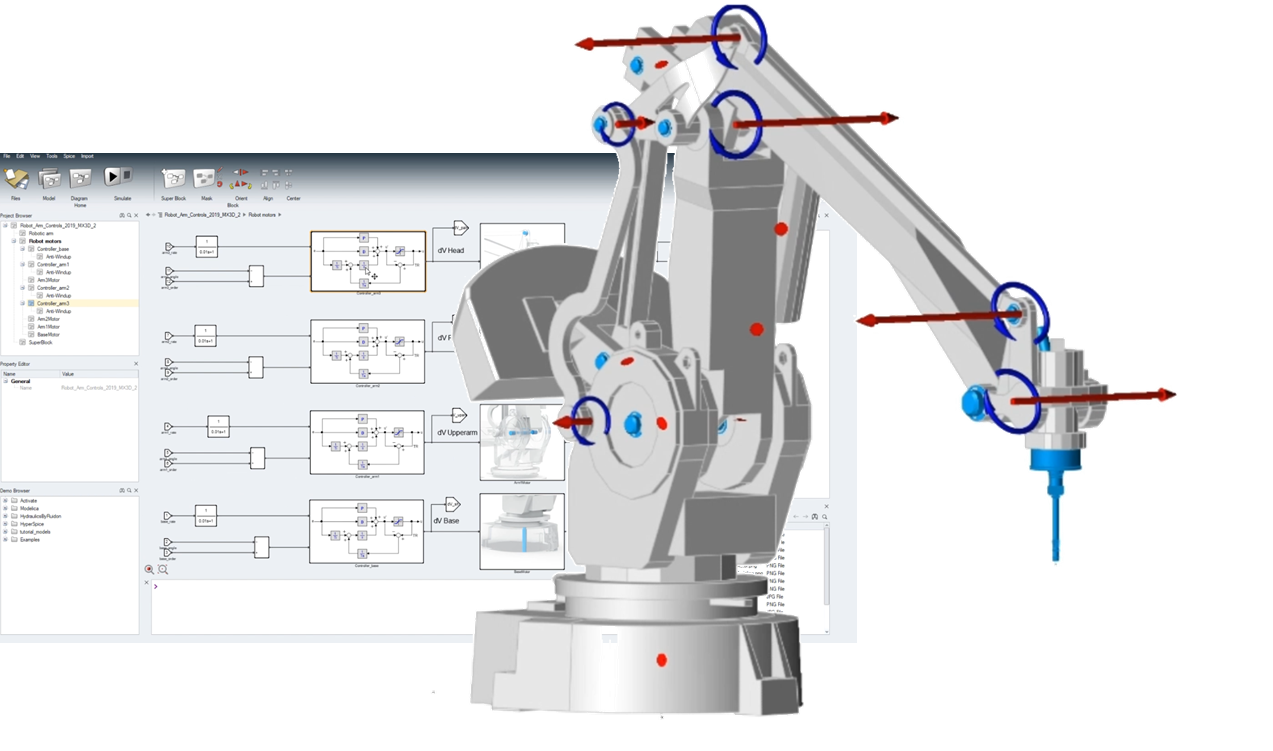

Creating a digital twin, understanding systems behavior

Creating a digital twin, understanding systems behavior

Sometimes the working envelope is specific when companies want to move objects that are just out of reach. This can be around a corner, behind a wall, or just out of reach of the standard working envelope. In this case customization is required beyond the OEMs standard product line.

Custom tooling is another scenario. Some companies design and manufacture their own top arm, because they need to mount specific tools onto the robot. When there are special requirements identified it can be well worth looking into customization to optimize the operation conditions. Handling improvements and less kinetic energy during acceleration and movement, will result in higher operation precision and overall reduced energy consumption.

Producing legacy parts (spare parts no longer in production) can also be an interesting application. Previously these casted parts could not be replicated which rendered them useless and an overall loss on capital investment.

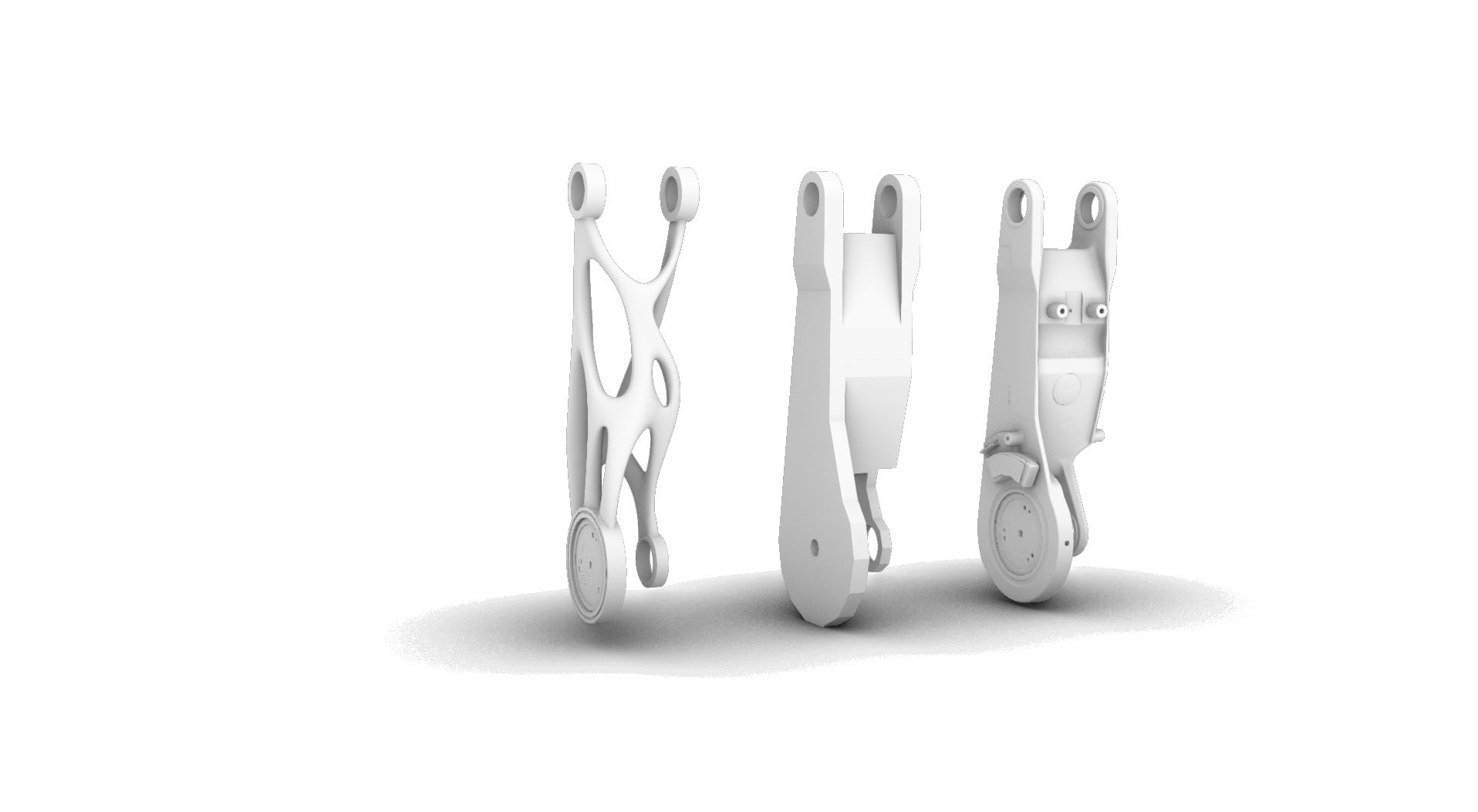

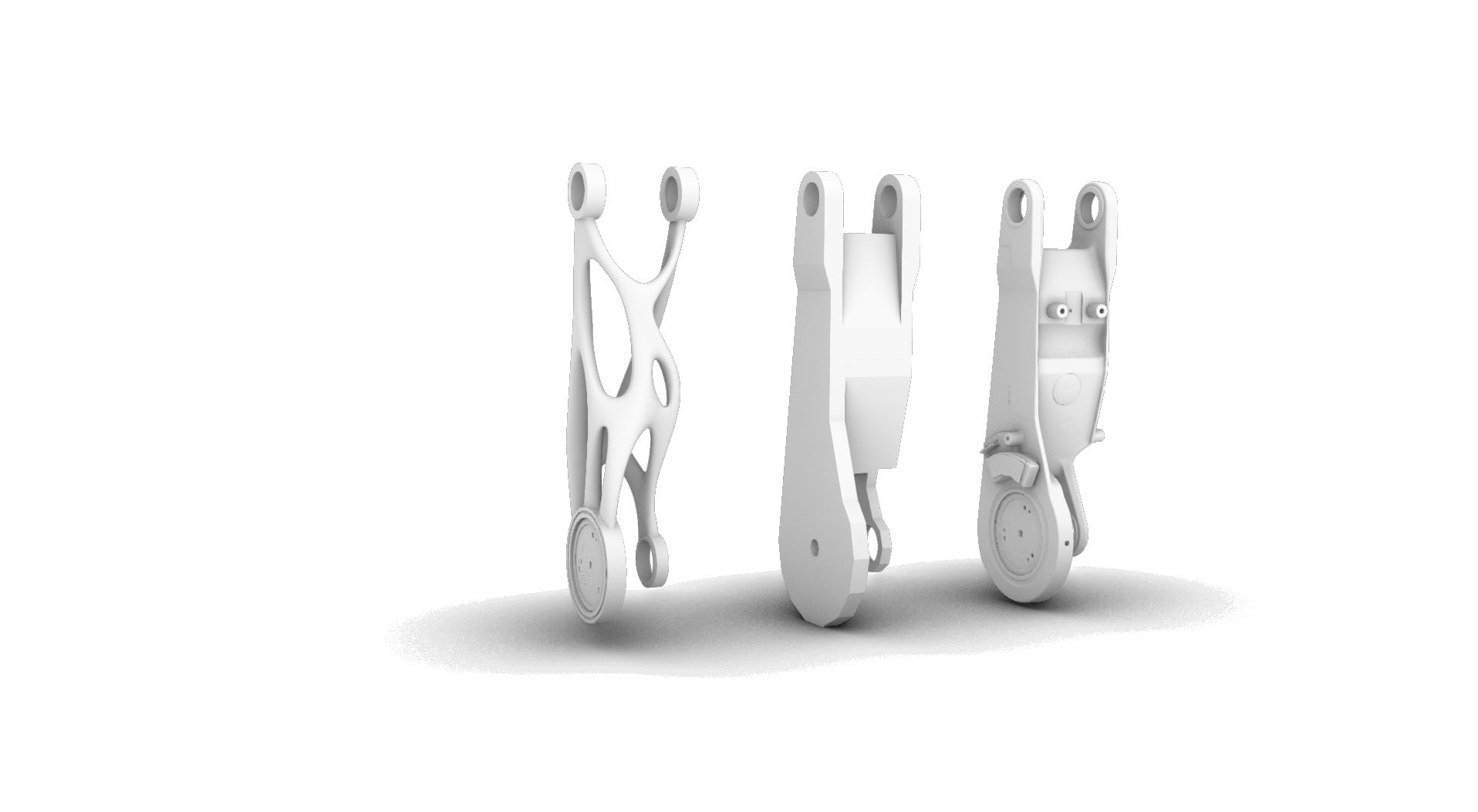

Evolution of the Robot Arm

Evolution of the Robot Arm

This is MX3D’s third project focused on the application of large-scale 3D metal printing for heavy equipment parts. The ABB robot arm was designed by Altair engineers using the material properties of the printed material. A digital twin design process was also used, to secure the generation of the most efficient shape and operation. The goal of the project was to show the WAAM technology in an industrial application. The project is the re-fit of a standard palletizer ABB robot, into a triple WAAM-unit.

The approach taken considered performance and precision requirements, the required function integration to integrate wire feeders, and all additional parts that needed to go on the system. The optimization task considered not only the loads coming from the accelerations of the system, but the wire feeders mounted. This included the torch and the hoses that ran through the arm for shielding gas, the active cooling for the torch, and the wire. The functional integration facilitates provided efficient guidance for all of the medium lines.

Altair Inspire at MX3D

MX3D receives project requests from many industries, so we are in need of development workflows that allow us to design and iterate quickly for our clients. Altair Inspire™ works well for us because we identify requirements and turn boundary conditions into a functional digital twin. We then comfortably generate quality optimized designs. Since it incorporates 3D printing constraints, we quickly showcase organic models that give our end users valuable insight into the possibilities with WAAM.

For the robot arm project, the identification of the requirements was crucial because we were not that familiar with this specific robot model. We worked closely with ABB to determine the load-case for our application. Collecting parameters from the datasheets and recreating the digital twin in the Altair Inspire environment, confirmed that we were on the right path for optimizing the arm.

The geometry creation capabilities allowed us to tweak the optimized model easily and move between our MX3D software platform for further refinement. This allowed quick iterations and we were able to incorporate specific manufacturing constraints.

Validate Robot performance in Altair Inspire

Validate Robot performance in Altair Inspire

Outlook

This designing methodology opened some interesting routes for WAAM manufacturing. We look forward to applying the digital twin design approach for our clients when we create the next generation of manufacturing parts and heavy equipment.

About MX3D

MX3D is a high-growth 3D metal printing company that earned its badge of honor by 3D printing a 12 meter, six ton stainless steel bridge for the city of Amsterdam. For this, they used four industrial robots that 3D printed stainless steel simultaneously. The technology for this project was developed by the company.

The MX3D bridge has been instrumented with an innovative sensor system. The goal is to develop a data centric design language for this technology by building a virtual testing environment using machine learning (ML).

The company will present its beta ‘Metal XL’ software at FormNext 2019. This software tool connects all aspects of the WAAM process: calibration, slicing, toolpath planning, process control, and data logging. At FormNext, two new projects will be revealed, a robot arm and a steel connector, both of which showcase effective uses of 3D printing through topology optimization.

Gijs van der Velden, CEO, MX3D

Gijs van der Velden, CEO, MX3D

Gijs van der Velden is the CEO of MX3D, a 3D metal printing company. Previously, Van der Velden was the general manager at Joris Laarman, which developed the large-scale robotic printing techniques now used by MX3D. Velden holds a master’s degree in Dutch and international law.

Wire Arc Additive Manufacturing (WAAM) 3D metal printing has now reached large-scale metal objects. This new technology has quickly been recognized as a gamechanger. MX3D is a forward-thinking company that is introducing WAAM to several high-impact industries. It develops software that makes large-scale industrial 3D metal printers by connecting an off-the-shelf industrial robot and welding machine.

As most industries are unfamiliar with this new technology, we at MX3D see ourselves as technology evangelists. With the MX3D Robot Arm project, we show the potential for in-house spare part and heavy equipment production. Every metalworking workshop can be turned into a mini-casting company, reducing lead-time and increasing design freedom.

Why customize an industrial robot? Industry robotics is a growing industry with a large variety of application classes. Many OEMs offer a wide variety of models for specialized applications. But there is a need for even more individualization.

Creating a digital twin, understanding systems behavior

Creating a digital twin, understanding systems behaviorSometimes the working envelope is specific when companies want to move objects that are just out of reach. This can be around a corner, behind a wall, or just out of reach of the standard working envelope. In this case customization is required beyond the OEMs standard product line.

Custom tooling is another scenario. Some companies design and manufacture their own top arm, because they need to mount specific tools onto the robot. When there are special requirements identified it can be well worth looking into customization to optimize the operation conditions. Handling improvements and less kinetic energy during acceleration and movement, will result in higher operation precision and overall reduced energy consumption.

Producing legacy parts (spare parts no longer in production) can also be an interesting application. Previously these casted parts could not be replicated which rendered them useless and an overall loss on capital investment.

Evolution of the Robot Arm

Evolution of the Robot ArmThis is MX3D’s third project focused on the application of large-scale 3D metal printing for heavy equipment parts. The ABB robot arm was designed by Altair engineers using the material properties of the printed material. A digital twin design process was also used, to secure the generation of the most efficient shape and operation. The goal of the project was to show the WAAM technology in an industrial application. The project is the re-fit of a standard palletizer ABB robot, into a triple WAAM-unit.

The approach taken considered performance and precision requirements, the required function integration to integrate wire feeders, and all additional parts that needed to go on the system. The optimization task considered not only the loads coming from the accelerations of the system, but the wire feeders mounted. This included the torch and the hoses that ran through the arm for shielding gas, the active cooling for the torch, and the wire. The functional integration facilitates provided efficient guidance for all of the medium lines.

Altair Inspire at MX3D

MX3D receives project requests from many industries, so we are in need of development workflows that allow us to design and iterate quickly for our clients. Altair Inspire™ works well for us because we identify requirements and turn boundary conditions into a functional digital twin. We then comfortably generate quality optimized designs. Since it incorporates 3D printing constraints, we quickly showcase organic models that give our end users valuable insight into the possibilities with WAAM.

For the robot arm project, the identification of the requirements was crucial because we were not that familiar with this specific robot model. We worked closely with ABB to determine the load-case for our application. Collecting parameters from the datasheets and recreating the digital twin in the Altair Inspire environment, confirmed that we were on the right path for optimizing the arm.

The geometry creation capabilities allowed us to tweak the optimized model easily and move between our MX3D software platform for further refinement. This allowed quick iterations and we were able to incorporate specific manufacturing constraints.

Validate Robot performance in Altair Inspire

Validate Robot performance in Altair InspireOutlook

This designing methodology opened some interesting routes for WAAM manufacturing. We look forward to applying the digital twin design approach for our clients when we create the next generation of manufacturing parts and heavy equipment.

About MX3D

MX3D is a high-growth 3D metal printing company that earned its badge of honor by 3D printing a 12 meter, six ton stainless steel bridge for the city of Amsterdam. For this, they used four industrial robots that 3D printed stainless steel simultaneously. The technology for this project was developed by the company.

The MX3D bridge has been instrumented with an innovative sensor system. The goal is to develop a data centric design language for this technology by building a virtual testing environment using machine learning (ML).

The company will present its beta ‘Metal XL’ software at FormNext 2019. This software tool connects all aspects of the WAAM process: calibration, slicing, toolpath planning, process control, and data logging. At FormNext, two new projects will be revealed, a robot arm and a steel connector, both of which showcase effective uses of 3D printing through topology optimization.

Gijs van der Velden, CEO, MX3D

Gijs van der Velden, CEO, MX3DGijs van der Velden is the CEO of MX3D, a 3D metal printing company. Previously, Van der Velden was the general manager at Joris Laarman, which developed the large-scale robotic printing techniques now used by MX3D. Velden holds a master’s degree in Dutch and international law.