SimLab Addresses the Needs of Product Engineers

Recently Engineering.com published the results of an audience survey, providing key takeaways to ensure a smoother implementation of simulation methods in their organization. This poll of 329 engineers, designers, and product managers produced some interesting findings about how companies use simulation as well as what the biggest roadblocks are in the way of technology adoption.

Takeaway #1: Part-time analysts play a large role in a company’s simulation ecosystem

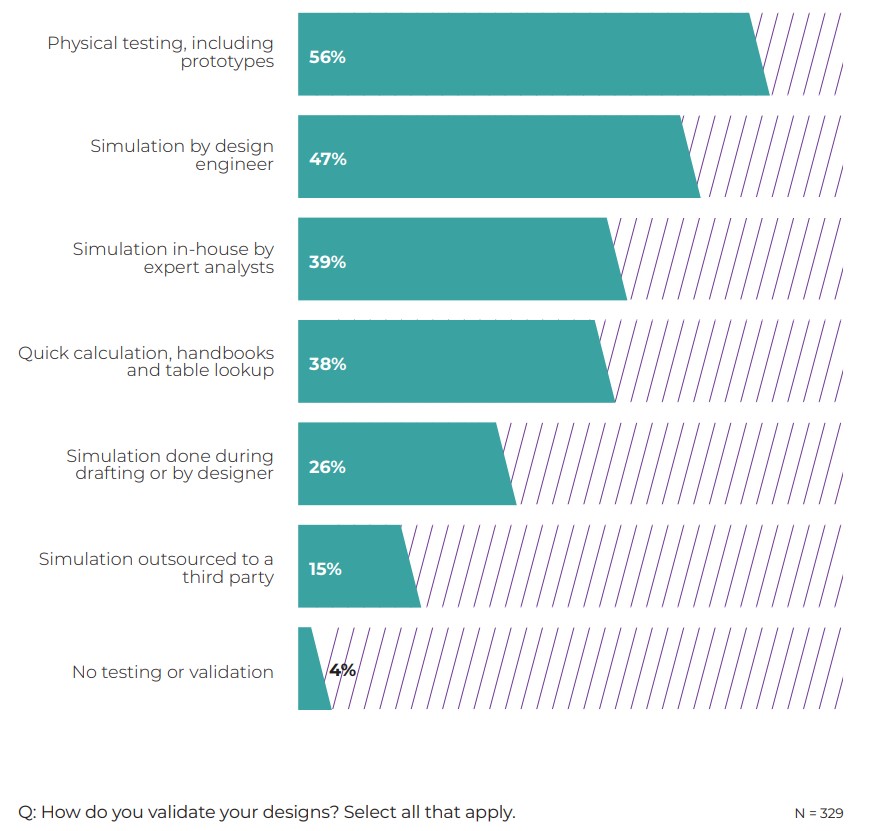

When asked “How do you validate your designs?”, nearly half of the audience (49 percent) responded that simulation work at their company is being undertaken by design engineers, while 39 percent have in-house expert analysts that conduct simulation work. While domain experts still play a pivotal role in the analysis of complex physics, a growing amount of design validation is being conducted by the product engineers themselves.

The use of simulation in early-stage design has shown to have great benefits for streamlining design workflows and reducing design and prototype iteration, but to fully realize the benefits, companies need to be confident that early-stage validation is accurate without creating undue burden on designers and delaying the product development process.

Takeaway #2: Simulation is Used for a Wide Array of Applications

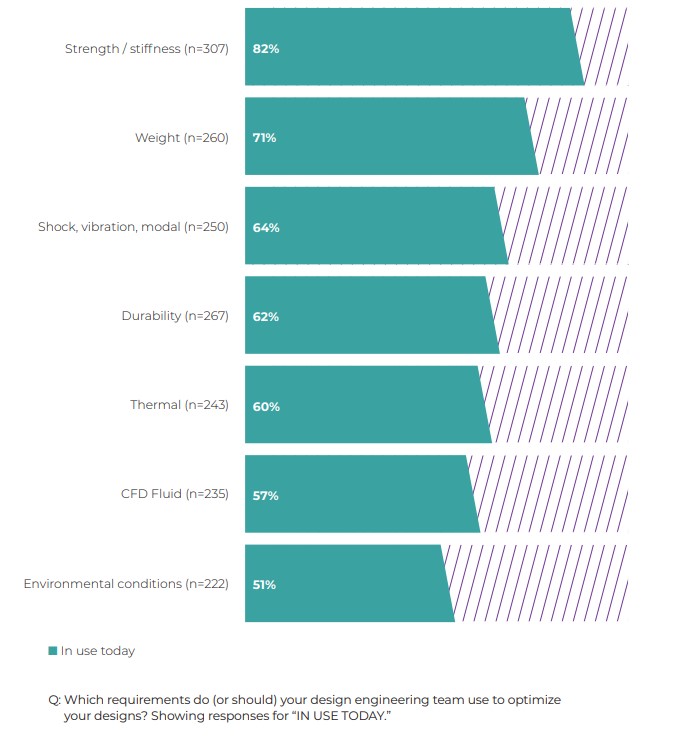

Adding to the complexity of the product engineer’s work, teams are expected to not only conduct strength and stiffness analysis and optimization, but also examine an array of additional physics that impact product performance.

57 percent of those polled said that their product engineering teams in their organization conduct CFD fluid simulation and 60 percent conduct thermal analysis. These are often thought of as the domain of expert analysts, but as more companies begin seeking an understanding of multiphysics and their effects on product design, product engineers will need designer-oriented tools to ensure accuracy and efficiency without sacrificing creativity and design freedom.

Takeaway #3: Solver knowledge and pre-processing efforts are simulation’s biggest roadblocks

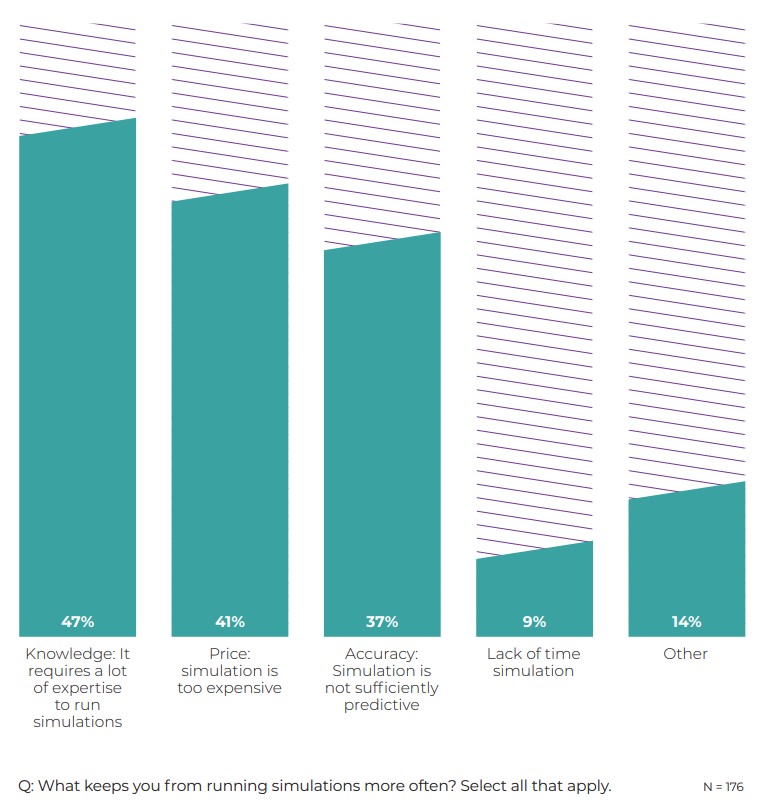

Training and expertise can be a major barrier to technology adoption, especially for product engineers tasked with performing multiple physics analyses. 47 percent of respondents listed solver knowledge as a contributing factor preventing them from doing more simulation, the most cited answer.

For product engineers, simulation tools that offer intuitive and easy to learn features seem to be imperative, but solutions cannot sacrifice accuracy in service of ease-of-use. 37 percent stated that accuracy was a driver in preventing their use of simulation. Designer-oriented user interfaces need to maintain simulation accuracy in order to justify the designer engineer’s efforts.

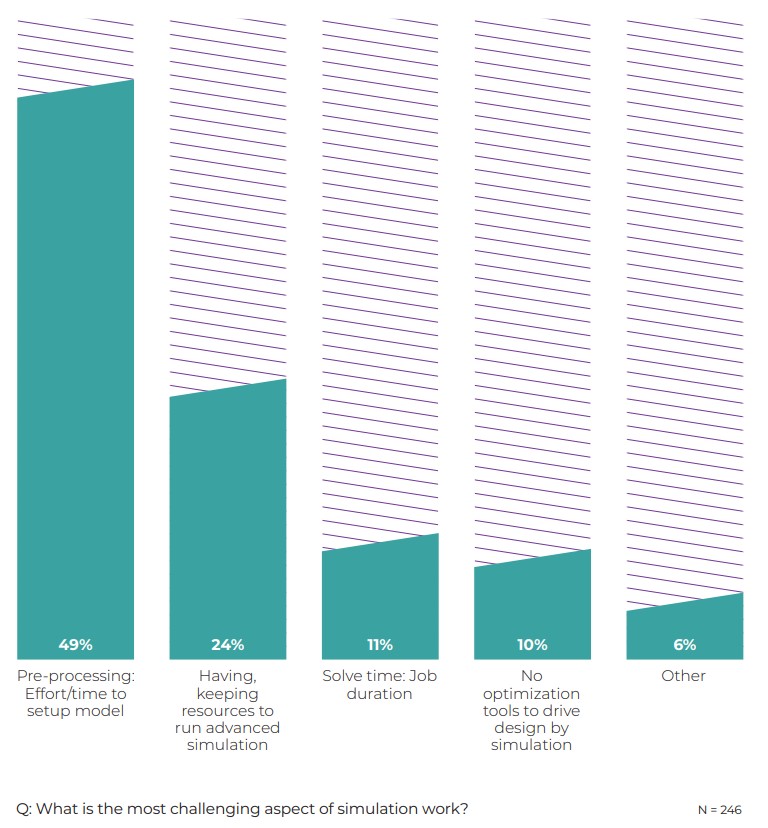

Finally, 49 percent of those polled said that pre-processing was the most challenging aspect of their simulation work. The effort and time required to set up models was the main source of pain for engineers conducting simulation.

Solutions for Overcoming Product engineers’ Challenges

Altair SimLabTM is a tool that delivers automated multiphysics workflows for faster analysis and optimization, in an environment built for product engineers and analysts. It delivers solver power without sacrificing accuracy or useability, helping companies scale up their simulation and drive design decisions using analysis and optimization results.

- Ensuring accuracy: Robust and repeatable workflows in SimLab mean fast, accurate, and consistent analysis, even for occasional simulation users. SimLab uses industry-trusted Altair solvers without the requirements for solver-specific knowledge.

- One platform, multiple physics: SimLab offers efficient model setup of multidisciplinary problems and multiphysics problems of coupled disciplines including structural, CFD, electromagnetics, thermal analysis, and manufacturing simulation.

- Reducing pre-processing effort: SimLab helps eliminate manual meshing, model setup, multiple physics complexity and post-processing configuration. Highly automated modeling tasks help to drastically reduce the time spent creating finite element models and interpreting results.

- Ease of use: An intuitive and self-explanatory graphical user interface covers all aspects of the modeling process. Instead of tedious geometry clean-up, work is performed directly on the geometry – imported and updated via the bi-directional CAD coupling - by defining mesh specifications for individual regions.

- Run solvers locally or in the cloud: Altair’s robust, accurate and scalable solvers can run either locally, on remote servers, or in the cloud.

For companies seeking to implement and expand their simulation-driven design strategies, this survey can be instructive to the challenges they may face when increasing their virtual design and analysis investment. It also demonstrates the ways a tool like SimLab helps alleviate these issues to ensure a smoother implementation of simulation methods across an organization.

To request a trial of Altair SimLab, click here. If you want to see the full survey results, download the report on Engineering.com.