Supercharge Product Development with SimSolid

As product development times are shrinking and time to market demands are accelerating, design and engineering teams are struggling to keep up. These teams are forced to make significant compromises in their products in order to meet internal and external release demands.

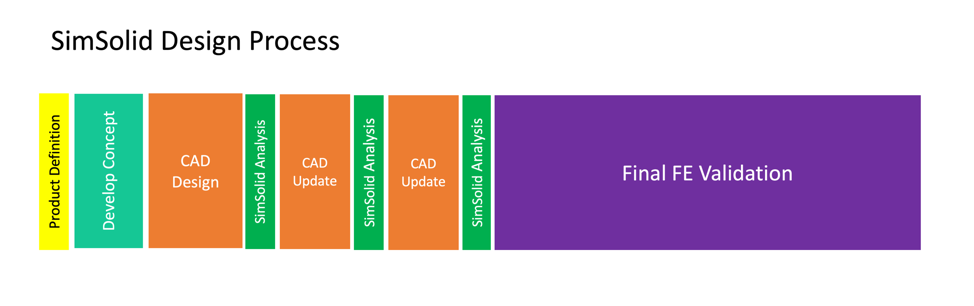

In talking to many people within the industry, we have found that the traditional design process looks similar to the flowchart below:

After developing the concept and working through an initial CAD design, we find our bottleneck, the finite element validation that verifies the design will survive all of the stresses and strains that it will experience during use. This step not only involves the actual analysis that often takes hours or even days to set up and run, but it also includes handoff to one or multiple different teams which can introduce bandwidth and scheduling difficulties. This timely step is often compounded when the simulation determines that the design does not meet all requirements. At this point, it is kicked back to the designer to try and shore it up and finally back to the verification team for another round of analysis. We call this back and forth process the iteration loop which can repeat a seemingly infinite number of times.

Knowing this is precisely why Altair invested in SimSolid™. As you likely know by now, SimSolid is the mesh free simulation tool that allows its users to accurately simulate extremely robust assemblies in almost real time. Contrary to the traditional design process that is detailed above, when SimSolid is added to the tech stack, an updated process emerges.

In the SimSolid design process above, you can see that the first three steps are the same, product definition, concept development, and CAD design. It is after these initial steps where we see the significant benefits. As opposed to the traditional process which required handoff to highly specialized tools and individuals, SimSolid can run analysis directly on the CAD geometry. Best of all, this analysis generally takes seconds to minutes, not hours to days. It is also incredibly accurate as we covered in detail in our earlier blog post.

From this new process, two immense benefits have emerged.

The obvious benefit of speed comes first. For teams constantly struggling with meeting time and release deadlines, adding SimSolid to the design process can help to significantly speed up the entire process. In fact, one of our customers, Renault implemented SimSolid and has been able to slash its simulation time down from two weeks to just half a day! Anthony Reullier, Digital Simulation Specialist at Renault Chassis in Le Mans will be presenting on how Renault is implementing and applying SimSolid to its design process in our free webinar on December 10. To learn more about the webinar and to reserve your spot, click here.

The second benefit we are seeing was not initially as obvious to us, however, it is incredibly powerful. Because SimSolid is so blazingly fast, its users are able to test multiple design iterations in literally minutes. When implemented early in the design process, we are seeing customers utilize SimSolid to truly drive the design process and ensure that the best design is the one that makes it to production.

SimSolid is truly taking the industry by storm, thousands of companies worldwide are discovering the tool and learning how to supercharge their design process. The mesh free simulation revolution is here, do not be left behind. Try SimSolid today and find out for yourself how valuable of a tool SimSolid really is.