The Pitfalls of a “Trial and Error” Approach to Manufacturing

Given that production processes are inherently complex, it’s not always easy making sure every aspect runs smoothly right off the bat. Considering all of the tools, materials, and especially the manufacturing approach that is used, companies are continuously looking for ways to improve their processes.

Finding a flaw in your manufacturing approach, however, can be intimidating. Companies who have always been comfortable with a conventional design process (physical prototype design, validation, redesign) may be hesitant to implement a new approach because of worries involving cost and time it takes to re-learn. Fortunately, modern technology has made it easy to bring simulation into the design process early and without complicated transitions. With all the scrap and rework costs that come with traditional “trial and error” approaches, simulation-driven design for manufacturing changes the game so that engineers no longer need to stress about multiple design reiterations and communication hassles between teams.

Inconsistencies lead to big expenses

The “trial and error” approach in manufacturing can ultimately lead designers down a repetitive path that consists of creating a mock-up design, putting it into production, and detecting design flaws too late. In most manufacturing industries, component reject rates tend to be around 5% to 10% but can be even higher in some complex shaped parts.

Finding these defects late, once a part or process is already in the works, becomes a really expensive situation to recover from in terms of both time and money. And it’s important to realize that those unnecessary costs can stem from inefficiencies in the manufacturing process itself. Finding the flaws in your manufacturing approach could be the key to major cost savings. That’s why companies are turning to simulation technologies so design errors can be corrected early and hassle-free. With simulation-driven design, back-and-forth between part and process design can be completely eliminated.

Inefficient processes slow time to market

The variables that play into product development, such as material type and quantity, tooling used, and cycle time, play complex roles at all different steps of manufacturing. Applying integrated simulation across the entire design process ensures that both design and process variables can be observed and optimized at the same time. It’s extremely important to avoid iteration loops between design and manufacturing for the sake of efficiency. Because while transparency between production teams is key, the end goal is to decrease product time to market and deliver a high-quality product to the customer without unnecessary costs at the expense of the manufacturer.

Correcting manufacturing defects during mold trials adds an average of 26% to the cost of mold.

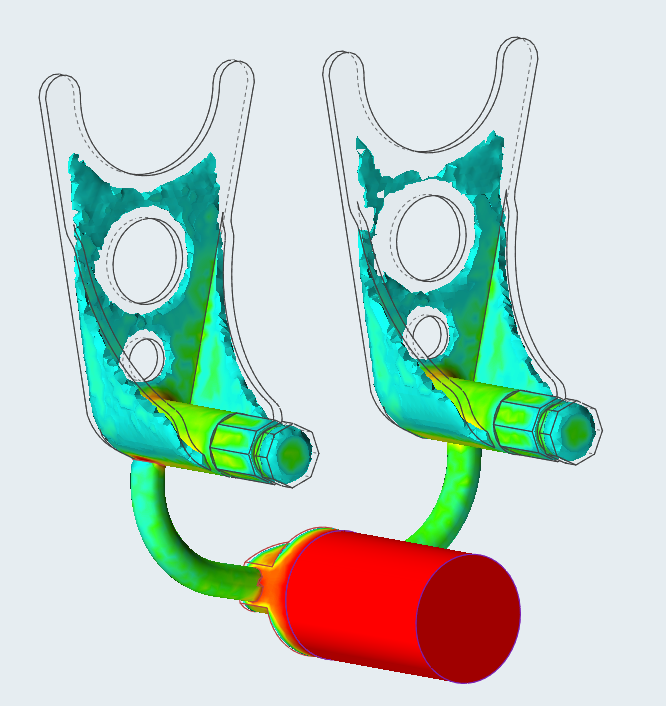

Manufacturing issues can slow down a product design process at the critical final stages of development. For instance, injection molded parts are often subject to warpage, sink marks, short shots, and other manufacturing inconsistencies, but these issues can be identified and corrected in the design phase with simulation software.

Over-designing results in wasted resource

Fewer physical prototypes means faster time to market, which also means less wasted resources, lower tooling costs, and less scrapped parts. Molds are costly, and both engineering and manufacturing teams want to find and fix potential defects ideally before a faulty part or product is put into a full production run. With access to a virtual product platform, development teams are less likely to endure wasted time and resources.

Based on a survey conducted by Tech-Clarity of 265 manufacturers, 61% of companies rated manufacturing defects as the biggest issue that negatively impacts competitiveness. When these defects aren’t found during design, the issues will begin on the production line and eventually affect relationships with customers, as well as overall workflow efficiency between the designers and manufacturers.

While some people still may view simulation as complex and hard to implement into an existing process, it is the opposite, and Altair’s simulation solutions make it easy to transition into a virtual environment. Providing tools for casting, molding, foaming, extrusion, and more, Altair’s simulation for manufacturing eliminates the need for constant design reiterations without disrupting current processes.

Use simulation to your advantage

By putting decision making directly in the hands of designers, the classic pitfalls that teams find themselves facing with traditional manufacturing practices can be avoided with an integrated simulation strategy. Overdesigning, wasted time, and inconsistent workflows are all the results of finding production problems late, rather than resolving them virtually at the start. Implementing simulation early adds in quality and part performance factors to production that leads to improved manufacturability.

Providing a full set of simulation tools for virtual design and manufacturing, Altair enables users to validate designs with simplicity and affordability all within a single, unified platform.