Thought Leader Thursday: Automotive Lightweighting Trends and the Altair Enlighten Award

The desire to reduce vehicle weight is as old as the vehicle itself. Henry Ford once famously said, “Excess weight kills any self-propelled vehicle” and “Strength has nothing to do with weight.” How fitting all these years later, that Ford Motor Company would win the 3rd annual Altair Enlighten Award after removing 700 pounds from their 2015 Ford F-150 truck.

In the past, although engineers have removed weight from vehicle designs, the introduction of new features like airbags, navigation systems, and infotainment systems added additional pounds to the vehicles. We have come to expect these new features, but also recognize that fuel economy has not significantly improved during this time.

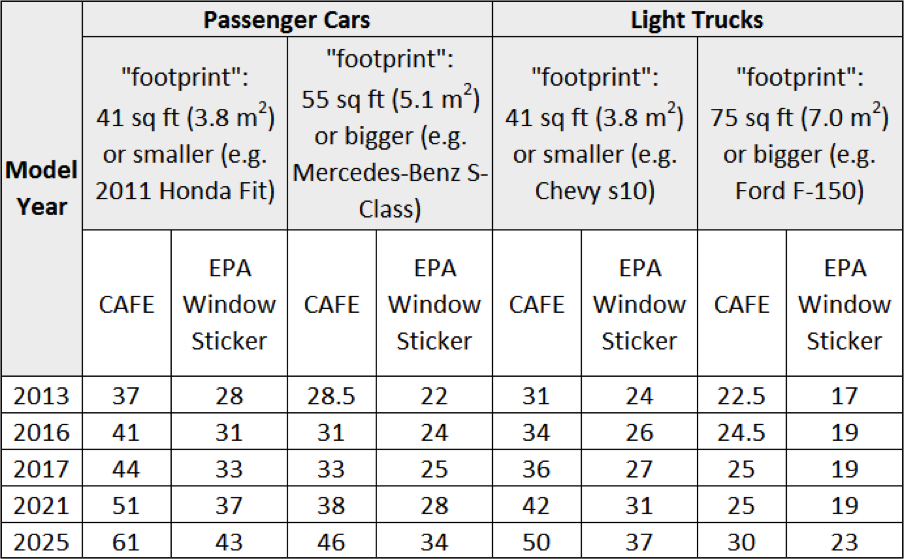

This will all change now that NHTSA has aggressively set new Corporate Average Fuel Economy (CAFÉ) standards. These new standards are introducing significant design challenges as automotive engineers release new vehicles from 2016 to 2025. As vehicle designs for 2016 are largely completed, we only have one or two design cycles left to meet the 2025 targets. The time is now for lightweighting.

Altair has been a thought and technology leader for lightweight design for more than 15 years. We tend to organize lightweighting into two primary categories, though a third interesting approach is emerging (more later).

First, we would identify Lightweight Material Removal (LMR) where design engineers today are using advanced optimization technologies, like Altair OptiStruct, to punch holes in the product, thin out the product’s form, or reshape the entire design. In many cases, this form of efficient design can be free, or even a cost save because it isn’t necessary to change manufacturing processes. This allows for removing material where it is not needed and ultimately saves on material costs.

The second category, Lightweight Material Substitution (LMS) results from replacing traditional heavy materials with new lighter alternatives, including high strength and advanced high strength steels, aluminum, magnesium, and composites. In terms of substituting materials, higher strength steels have been introduced over the last 5-10 years as they are easier to implement, requiring less change in the design and manufacturing process. Recently, we have witnessed significant aluminum vehicle content included in the aforementioned Ford F-150, the 2014 Altair Enlighten award winning Jaguar Land Rover, and many others.

Likewise, we are witnessing significant growth for composites in automotive design. Bolt-on applications where components are attached in areas separate from the body assembly are becoming common. Some more notable bolt-on applications include the hoods of the 2014 Corvette Stingray and the 2013 Viper SRT. More aggressive applications where composites are integral in the body design are also coming to market. We see this primarily in premium luxury vehicles like the new BMW i3 passenger compartment.

Picture courtesy of General Motors: http://media.gm.com/media/us/en/gm/news.detail.html/content/Pages/news/us/en/2013/Feb/0212-corvette.html

Picture courtesy of General Motors: http://media.gm.com/media/us/en/gm/news.detail.html/content/Pages/news/us/en/2013/Feb/0212-corvette.html

I would personally like to congratulate Ford for winning the 2015 award. The F-150 was selected as the winner for its reduction of 700 pounds (318 kg) while simultaneously improving overall performance, safety and efficiency. Ford’s engineers took a holistic approach to weight reduction by incorporating advanced materials into the entire design of the vehicle, including the frame, body, powertrain, battery and interior features such as the seats. The weight savings helps the truck tow more, haul more, accelerate quicker and stop shorter, and contribute to greater fuel efficiency.

High-strength, military-grade aluminum alloys were used throughout the F-150 for the first time, saving approximately 400 pounds (181 kg) from the vehicle’s body. Ford’s engineering, research, and manufacturing teams overcame the challenge of shifting from the traditional steel body to the advanced aluminum production. This was a noteworthy example of taking aluminum to a high volume application.

The biggest deployment challenge is the cost of these new lightweight materials as automakers must keep final vehicle prices affordable for their target customer. Design engineers are now recognizing that they should always use material removal (LMR) optimization technologies, even when substituting new materials. Utilizing LMR optimization technologies promises the most efficient and cost-effective use of the material. These technologies will carry us forward as the automotive industry rises to meet the CAFÉ standards by 2025. As Henry Ford said, the need for weight reduction is critical for self-propelled vehicles and his statement is just as true today as it was when the automotive industry began over 100 years ago.

In the past, although engineers have removed weight from vehicle designs, the introduction of new features like airbags, navigation systems, and infotainment systems added additional pounds to the vehicles. We have come to expect these new features, but also recognize that fuel economy has not significantly improved during this time.

This will all change now that NHTSA has aggressively set new Corporate Average Fuel Economy (CAFÉ) standards. These new standards are introducing significant design challenges as automotive engineers release new vehicles from 2016 to 2025. As vehicle designs for 2016 are largely completed, we only have one or two design cycles left to meet the 2025 targets. The time is now for lightweighting.

Can we meet these fuel economy targets?

Automakers are exploring all possible methods to meet these new fuel economy targets, including alternative powertrain technologies, aerodynamic improvements, low rolling resistance tires, and many more. Addressing the age-old concept of lightweighting the vehicle itself is becoming the key topic of meeting these targets.Altair has been a thought and technology leader for lightweight design for more than 15 years. We tend to organize lightweighting into two primary categories, though a third interesting approach is emerging (more later).

First, we would identify Lightweight Material Removal (LMR) where design engineers today are using advanced optimization technologies, like Altair OptiStruct, to punch holes in the product, thin out the product’s form, or reshape the entire design. In many cases, this form of efficient design can be free, or even a cost save because it isn’t necessary to change manufacturing processes. This allows for removing material where it is not needed and ultimately saves on material costs.

The second category, Lightweight Material Substitution (LMS) results from replacing traditional heavy materials with new lighter alternatives, including high strength and advanced high strength steels, aluminum, magnesium, and composites. In terms of substituting materials, higher strength steels have been introduced over the last 5-10 years as they are easier to implement, requiring less change in the design and manufacturing process. Recently, we have witnessed significant aluminum vehicle content included in the aforementioned Ford F-150, the 2014 Altair Enlighten award winning Jaguar Land Rover, and many others.

Likewise, we are witnessing significant growth for composites in automotive design. Bolt-on applications where components are attached in areas separate from the body assembly are becoming common. Some more notable bolt-on applications include the hoods of the 2014 Corvette Stingray and the 2013 Viper SRT. More aggressive applications where composites are integral in the body design are also coming to market. We see this primarily in premium luxury vehicles like the new BMW i3 passenger compartment.

Smart Materials?

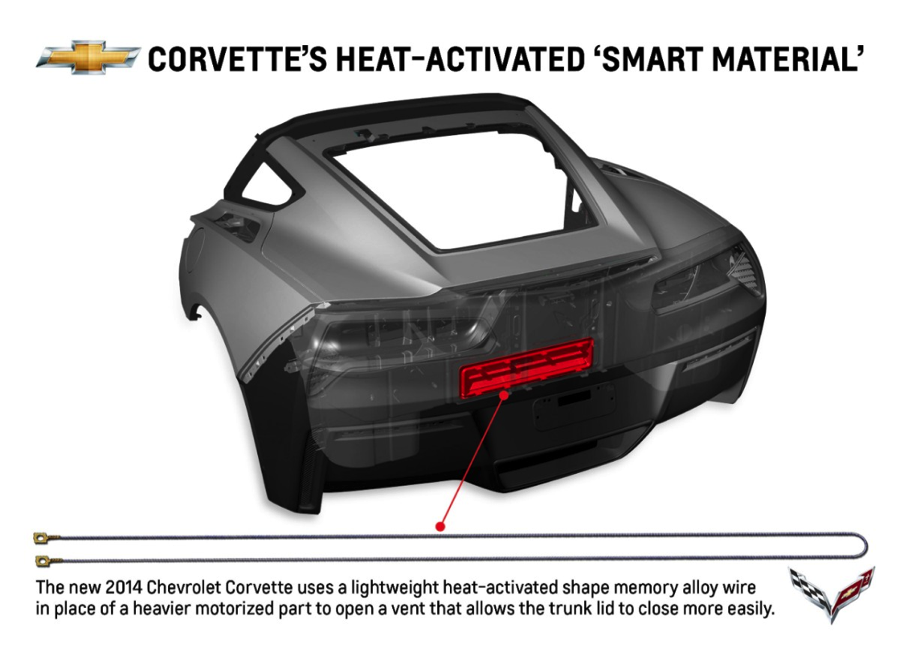

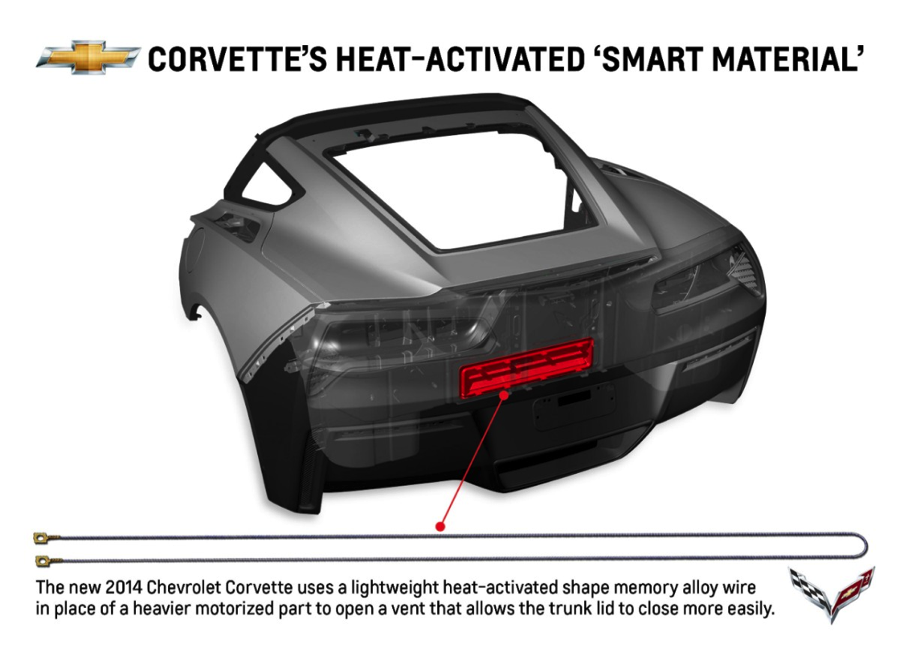

One new very interesting lightweighting approach is the use of shape memory alloys to replace heavier motorized actuators and mechanisms, which we can call “smart materials.” General Motors designed a lightweight shape memory alloy wire to open and close the hatch vent that releases air from the trunk on the 2014 Corvette. General Motors states that there are about 200 motorized movable parts on a typical vehicle that might possibly be replaced with lightweight smart materials to provide future weight savings. Picture courtesy of General Motors: http://media.gm.com/media/us/en/gm/news.detail.html/content/Pages/news/us/en/2013/Feb/0212-corvette.html

Picture courtesy of General Motors: http://media.gm.com/media/us/en/gm/news.detail.html/content/Pages/news/us/en/2013/Feb/0212-corvette.htmlThe Altair Enlighten Award

The 2015 Altair Enlighten Award celebrates vehicle lightweighting, and was created to honor the greatest achievements in automotive weight savings each year. The award is meant to inspire interest from industry, engineering, policy makers, educators, students and the public. It is also intended to create further competition for new ideas in the industry and to provide an incentive to share technological advances in vehicle lightweighting. The award is presented in collaboration with the Center for Automotive Research (CAR).I would personally like to congratulate Ford for winning the 2015 award. The F-150 was selected as the winner for its reduction of 700 pounds (318 kg) while simultaneously improving overall performance, safety and efficiency. Ford’s engineers took a holistic approach to weight reduction by incorporating advanced materials into the entire design of the vehicle, including the frame, body, powertrain, battery and interior features such as the seats. The weight savings helps the truck tow more, haul more, accelerate quicker and stop shorter, and contribute to greater fuel efficiency.

High-strength, military-grade aluminum alloys were used throughout the F-150 for the first time, saving approximately 400 pounds (181 kg) from the vehicle’s body. Ford’s engineering, research, and manufacturing teams overcame the challenge of shifting from the traditional steel body to the advanced aluminum production. This was a noteworthy example of taking aluminum to a high volume application.

Looking Forward

The reality is that future vehicles will be mixed-material where we use the best material for each component. Material selection will depend on whether the performance requirement is based on stiffness, energy absorption, or fatigue life. We will overcome challenges to the mass deployment of these new mixed-material vehicles step by step, by reducing time required to qualify new materials and overcoming the cost of modernizing established infrastructure.The biggest deployment challenge is the cost of these new lightweight materials as automakers must keep final vehicle prices affordable for their target customer. Design engineers are now recognizing that they should always use material removal (LMR) optimization technologies, even when substituting new materials. Utilizing LMR optimization technologies promises the most efficient and cost-effective use of the material. These technologies will carry us forward as the automotive industry rises to meet the CAFÉ standards by 2025. As Henry Ford said, the need for weight reduction is critical for self-propelled vehicles and his statement is just as true today as it was when the automotive industry began over 100 years ago.