Altair’s Solutions for Steel Bridge Competitions

Altair's engineering solutions offer invaluable support throughout the design process to students and teams participating in steel bridge competitions, such as the American Institute of Steel Construction’s Steel Bridge Competition. From preliminary design to global analysis and digital validation, Altair's software empowers teams to optimize their designs to reach their goals. With it, student teams can not only leverage their own experiences, but also powerful simulation and modeling capabilities to explore various design iterations, assess structural integrity under different loading conditions, and ensure design code compliance. This allows students to explore more concepts faster.

Preliminary Design Exploration

Every year, talented engineering students from around the world come together to conceptualize, analyze, fabricate, test, assemble, and ultimately compete to design award-winning steel bridges. Each year the competition rules change – after all, no two real-world bridge projects are the same – meaning there’s no “one size fits all” solution for each design. In other words, one success in one competition doesn’t guarantee success in another, since each use case is unique.

This is where conception planning and optimization is invaluable. Altair® Inspire™ can be a game-changing tool early in the design process to guide decision-making. Using industry-leading topology optimization technology, students can create a design space that can determine bridges’ ideal material layout based off user-defined objectives, constraints, loads, and more. This can provide critical insight into load path distributions and help predict material layout for an ever-changing set of design constraints.

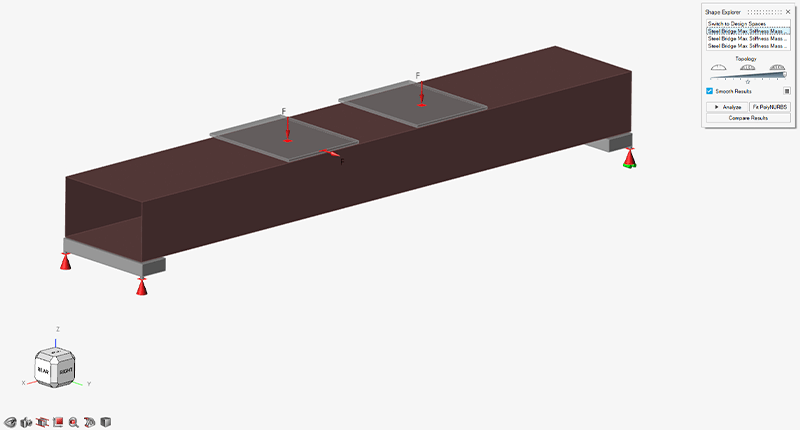

Figure 1: Design space in brown, with applied loads and supports.

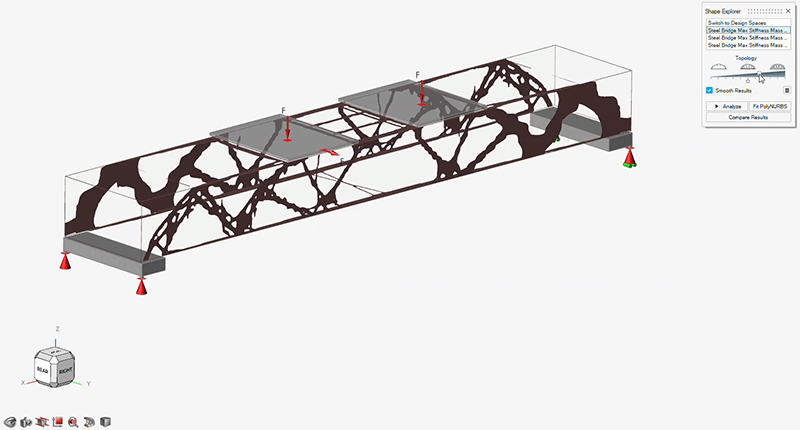

Figure 2: Topology optimization result #1.

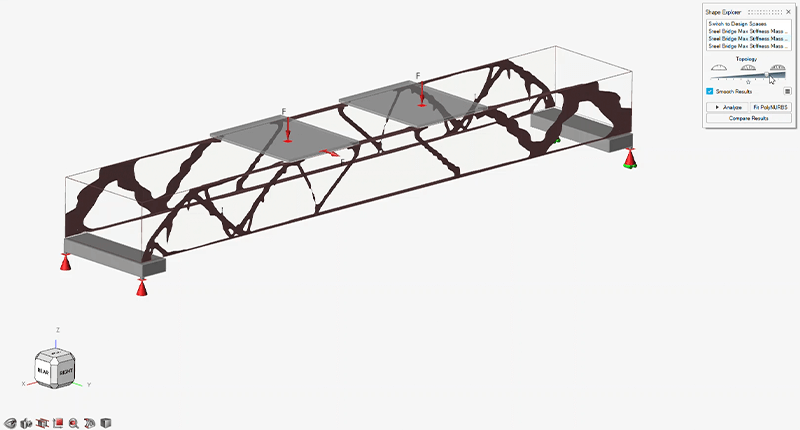

Figure 3: Topology optimization result #2.

After the preliminary design concepts have been evaluated, when students wish to take the next step within structural analysis, the optimized shape can be rationalized to represent the desired structure. It’s here where students put on their “engineering caps” to decide questions including, but not limited to:

- What size sections do I use?

- Do I use plates, or truss systems?

- How should my members transfer loads from one to the other?

- What loads will need to be considered during the construction process?

Global Structural Analysis and Code Validation

This process may involve a combination of optimization data, practicality (buildability), and more to come up with the structural analysis that can be analyzed, validated, and refined in Altair® S-FRAME®.

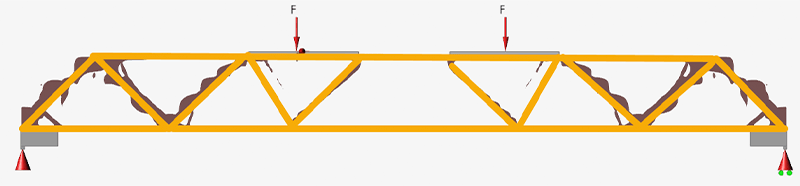

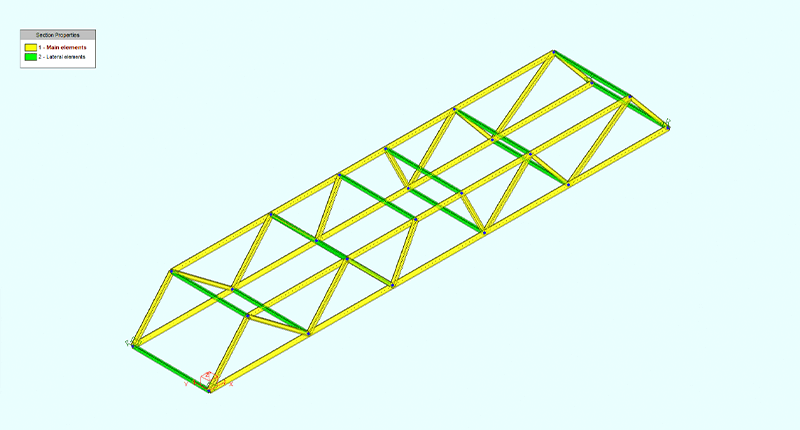

Figure 4: Rationalization of optimization result to 1D elements (elevation view).

Figure 5: Rationalization of optimization result (isometric view).

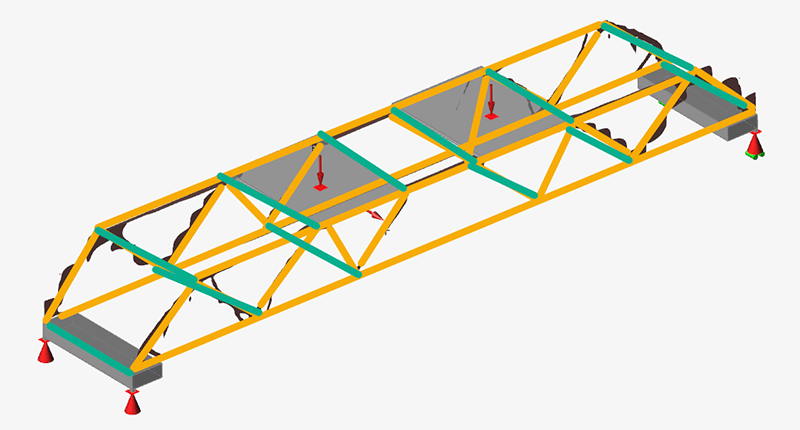

Figure 6: S-FRAME model with assigned sections (isometric view).

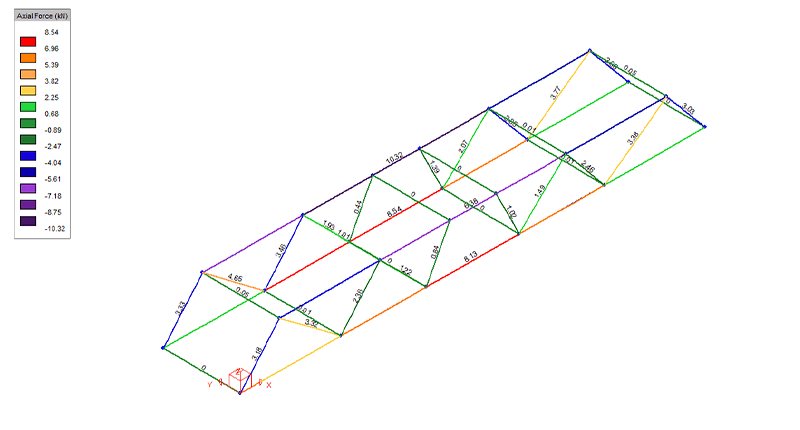

Figure 7: Axial force diagram

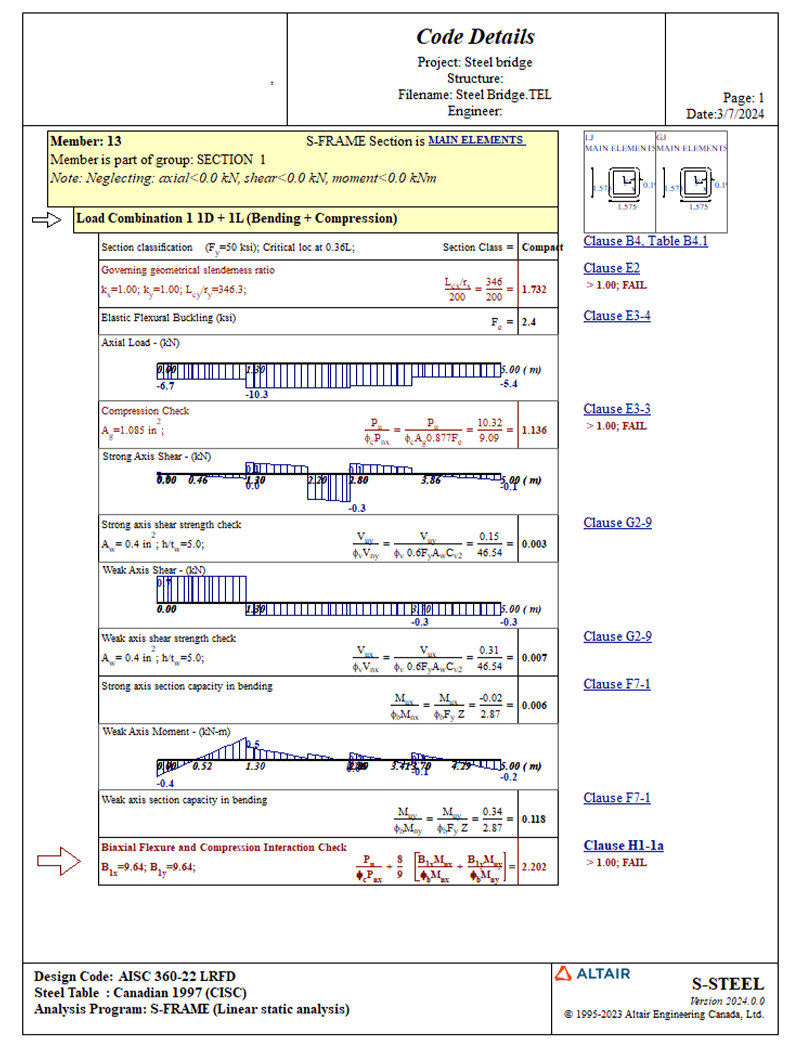

Within Altair S-FRAME, models can be idealized to 1D or 2D finite elements, analyzed, and validated against design codes while considering as many loading conditions as needed. S-FRAME provides an intuitive interface that allows for easy modification at any point within the design process using a graphical or numerical interface. This makes for an ideal environment to quickly test alternative designs and even run sensitivity analyses. S-FRAME also facilitates the validation of steel sections against the latest steel design codes to ensure a safe design, with transparent engineering design reports produced with the click of a button.

Figure 8: Steel design report

Physical Testing in a Digital Environment

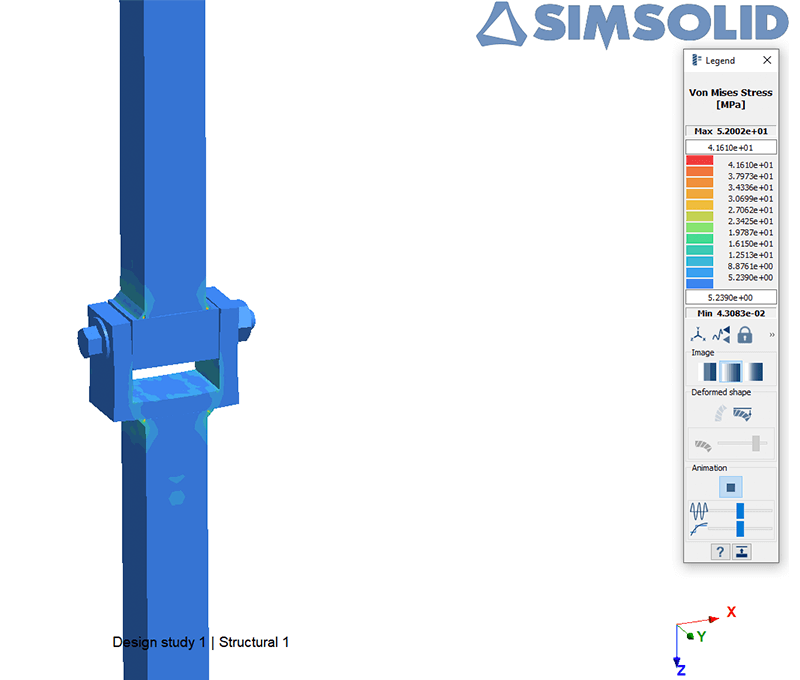

Something we haven’t yet touched on is how the steel members are connected to one another. These connections must be capable of withstanding the loads transferred through it, while still being lightweight and easy to install. A natural way to evaluate connections’ strength is by performing physical tests on fabricated joints. The challenge with this is that these tests cost money and take time, two things that student teams don’t always have in abundance. For this reason, we suggest Altair SimSolid® as a digital alternative to physical testing.

Altair SimSolid can import 3D CAD geometry from industry standard formats (Solidworks, Inventor, ProEngineer, Inspire, Tekla, AutoCAD, etc.) and perform structural analyses without the need for simplification or geometry clean-up. The best part is that this analysis can be performed in seconds, without needing to undertake the arduous task of meshing. This enables students to efficiently study design alternatives in a digital environment, allowing them to focus their physical tests on pre-validated designs. Altair SimSolid allows for the study of models on a local and global scale while evaluating model stresses, weld forces, bolt forces, and more.

Figure 9: Von Mises stress plot for single bolt connection

The aforementioned solutions are available to university students competing in steel bridge competitions, and provide a great opportunity to use industry-grade analysis and design solutions while gaining valuable technical skills. Interested in obtaining a personal license of S-FRAME or Inspire? Visit https://admin.altairone.com/register to learn more.