What Do Engineers Want from FEA Software?

Streamline simulation with fast and accurate meshing tools

To tackle today’s complex design challenges, mechanical engineers need flexible, reliable, easy-to-use, and comprehensive tools at their fingertips. These tools should not only help them quickly understand and solve complex technical problems; they should also have powerful visualization capabilities to make it easier to communicate and sell their ideas. At the same time, these tools should take care of tedious, time-consuming, and repetitive tasks, so engineers can focus on innovation.

Let’s see how Altair® HyperMesh® does just that.

1. Accuracy and Reliability of Results

Overall, engineers need trustworthy results that are proven to closely match real-world physical behaviors. Everybody wants to avoid an error in analysis that can lead to overdesign (excess weight, material, and cost) or part failure (avoidable safety, warranty, and reputation issues).

Though accuracy is essential for certification and safety, speed is key when it comes to design exploration and trade-offs analyses. At this stage, engineers don’t want to wait for answers while running huge models that eat up massive amounts of compute resources. Especially when surrogate models produce results “good enough” to point that engineer down the best design path.

Having the flexibility to choose between fidelity is key to engineers as their designs evolve.

2. Ease of Use and Workflow Efficiency

All engineers want to focus on the problem at hand, not waste time and effort wrestling with a software’s user interface (UI). Therefore, FEA software must have intuitive UIs, geometry import (from CAD), geometry update, meshing, and other pre- and post-processing workflows. Often, CAD imports require some clean-up, including repairing geometry and preparing parts for meshing; HyperMesh makes this step fast, accurate, and hassle free.

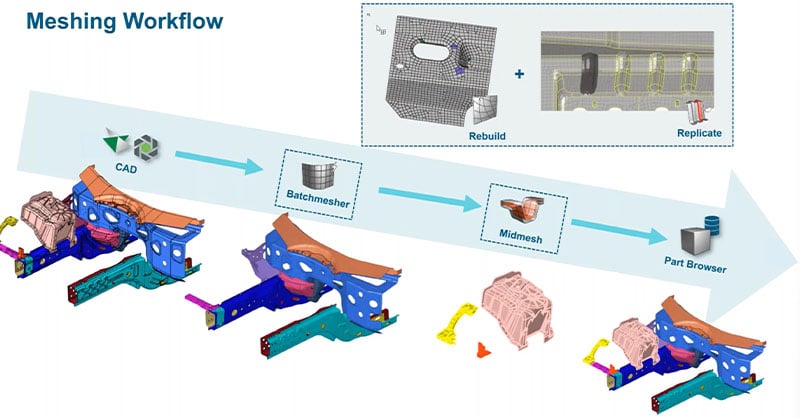

Let’s talk meshing. Though it can be repetitive and tedious, engineers know it is fundamental to ensure simulation accuracy, good convergence, low element distortion, and performance capture. HyperMesh offers high‑quality, flexible meshing that is ideal for complex geometries, large assemblies, and mixed element types. It includes tools for surface and solid meshing, morphing, mid‑surface extraction, and large assembly management.

With only a few clicks in HyperMesh, large models are meshed automatically. This process generates a high-quality, solver-ready input in minutes, not hours. Nonetheless, engineers still have the control to manually modify or fine-tune elements in problem areas.

With its modern, intuitive UI, HyperMesh offers import from all major CAD packages, a series of guided workflows for common analyses, batch solving, and automated Python scripting.

- Explore more about meshing and elements in HyperMesh.

- Dive deeper into meshing with step-by-step HyperMesh tutorials.

- Watch practical, in-action examples on the Altair How-to YouTube channel. Click here for a guided example on meshing and geometry operations. For more on HyperMesh automation and Python capabilities, click here.

An example of a meshing workflow with various tools that automatically generate a mesh. Engineers have the option to invoke them interactively during a HyperMesh session.

3. Speed and Solver Performance

When running large assemblies, design iterations, and optimizations, engineers want quick solve times to attain faster design cycles and better results. HyperMesh is solver agnostic, and it delivers fast pre- and post-processing speed. It also streamlines preparation, so solver time and cost are optimized.

4. Versatility Across Physics and Materials

Modern design approaches mean engineers need multiphysics problem solving tools. They enable them to combine factors like material properties, thermal, electromagnetic, structural, and fluid-structure interaction to truly optimize a design.

Being a fully integrated tool, HyperMesh offers topology optimization, structural, crash, durability, fatigue, NVH, and CFD, without the need to switch, run, or convert from different models. This streamlined workflow improves speed, productivity, and consistency.

5. Visualization and Post-Processing Tools

Fast solve times mean nothing unless they are backed by efficient post-processing. HyperMesh offers unambiguous, high-quality visualizations, such as custom plots, animations, and automated reporting tools. This not only helps engineers understand problems and communicate insights, it also enables data analysis and improves decision making.

6. Technical Support and Flexible Licensing

For decision-makers, licensing considerations such as cost, accessibility, and both on-site and cloud availability are critical. In these areas, HyperMesh excels. For hands-on engineers, HyperMesh offers best-in-class onboarding with an intuitive UI, supported by Altair’s comprehensive eLearning resources and dedicated technical teams.

Meshing doesn’t have to be slow or tedious. With HyperMesh, engineers gain faster meshing times, precise control over the mesh, and the flexibility to work with any solver or CAD system. Automation, scripting, and streamlined workflows make handling complex parts easier than ever. Watch this recorded webinar to see these capabilities in action and learn how to accelerate your simulations while maintaining accuracy.