What Do Directors of Engineering Want from FEA Software?

Like hands-on FEA engineers, team leaders want reliable, easy-to-use, and comprehensive tools they can count on when needed. But their priorities go further: they need to demonstrate measurable benefits today, while future-proofing their organizations with greater efficiency, ROI, and productivity.

Let’s explore how Altair® HyperMesh® does just that.

1. Efficiency and ROI

By speeding up CAD import and “clean up,” HyperMesh brings instant benefits in efficiency and use of resources. It also offers high‑quality, flexible meshing processes (ideal for complex geometries, large assemblies, and mixed elements) using tools like surface and solid meshing, morphing, and mid‑surface extraction.

With its modern, intuitive UI, HyperMesh imports geometry from all major CAD packages. It then offers a series of guided workflows for common analyses and batch solving. Teams can even automate processes — like report generation — using Python scripts.

By reducing pre-processing efforts, development cycles are faster, making time-to-market quicker than the competition.

2. Standardization Across Global Teams

>An organization’s growth cannot be throttled by its software resources. Today’s workforce is global, meaning projects can be active 24 hours a day, so consistent access to tools is crucial to keep projects on track.

As a fully integrated tool, HyperMesh offers unlimited scalability and flexible licensing, with on-site and cloud solutions. Teams gain access to comprehensive software 24 hours a day. This ensures organization-wide access where everyone is using proven processes and standards. The tool also ensures full traceability, so teams can be “singing the same song” wherever they are in the world.

3. Openness Protects Investments

Changing a software vendor is considered impossible by some. It takes a lot of time, money, and effort to transfer, without error, prior project data and systems into new acceptable formats.

The HyperMesh open, solver-agnostic approach eliminates vendor lock-in by serving as a single tool for all solvers. For organizations of every size, this means past and current project data, future software investments, and established engineering processes are protected.

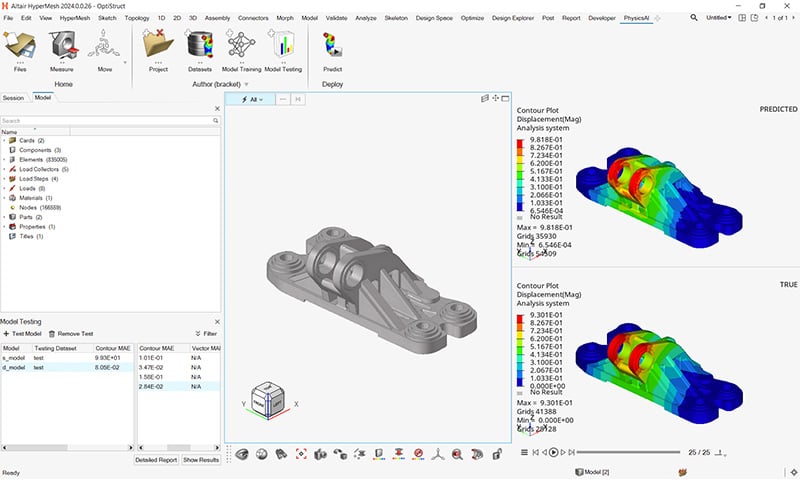

Shown here is a displacement analysis in HyperMesh with Altair® PhysicsAI™, which automates predictions by learning from past simulations. Engineers can quickly compare AI-driven and traditional results, saving time and reducing costs while delivering accurate results.

4. Better Resource Utilization

HyperMesh delivers faster meshing and correction, saving time without compromising quality. With only a few clicks, HyperMesh automatically meshes large models to generate a high-quality, solver-ready input in minutes, not hours. So, teams accomplish more by releasing engineers from tedious, time-consuming tasks — like meshing.

With the control to manually modify elements in problem areas, users can fine-tune a mesh exactly where it’s needed. Better quality meshing means valid simulation results, with less compute time and reruns.

Use of automation and scripting also improve job throughput while ensuring enterprise-wide repeatability and scalable processes that meet standards and traceability.

HyperMesh’s open philosophy means interoperability with all common CAD packages and third-party solvers, so only one meshing tool is needed for all teams.

To summarize, optimized, guided, and AI-embedded workflows in HyperMesh ensure model build and assemblies, solver setup, report generation, and pre- and post-processing are all significantly faster — with some benchmarked workflows speeding up from hours to minutes.

With HyperMesh, do more, and faster, without increasing headcount or sacrificing quality.

To learn more about the value HyperMesh brings for projects of all sizes, including an overview of its meshing, automation, and interoperability capabilities, check out this webinar: https://altair.com/resource/experience-the-next-generation-of-altair-hypermesh-for-unparalleled-performance-in-advanced-3d-and-surface-meshing.