Optimizing Materials to Create a Quieter Life

This post on Innovation Intelligence is written by Luc Jaouen, an expert in the vibration and acoustics field and owner of MATELYS Research Lab. MATELYS is a member of the Altair Partner Alliance.

First, the characterization of the intrinsic parameters of materials allows to identify the dissipation mechanisms governing the material responses. This can be done using measurements or computational approaches (based on e.g. micro-macro or virtual prototyping approaches).

Second, thanks to this knowledge, there is no need to work on complicated models. Simple geometries work better. The Transfer Matrix Method (TMM), a quick analytical technique as implemented in AlphaCell (available via the Altair Partner Alliance) is a more convenient technique than the Finite Element Method (FEM) to optimize the material arrangement.

Last but not least, it is important to capitalize on the acquired knowledge. Let's keep it simple for better customer usability. Web based smart tools are a good alternative to disseminate the results of the study and to let the team appropriate the results. As an illustration, the example below shows a modification of the strut thickness and simultaneous impact on the acoustic, elastic and thermal properties of the foam made of this strut morphology.

Foams, together with air-flow constraints, were identified to fulfill the sound absorption target. An optimization procedure relying on TMM simulations allowed the selection of the optimal material properties and the implementation of the optimized vacuum cleaner solutions.

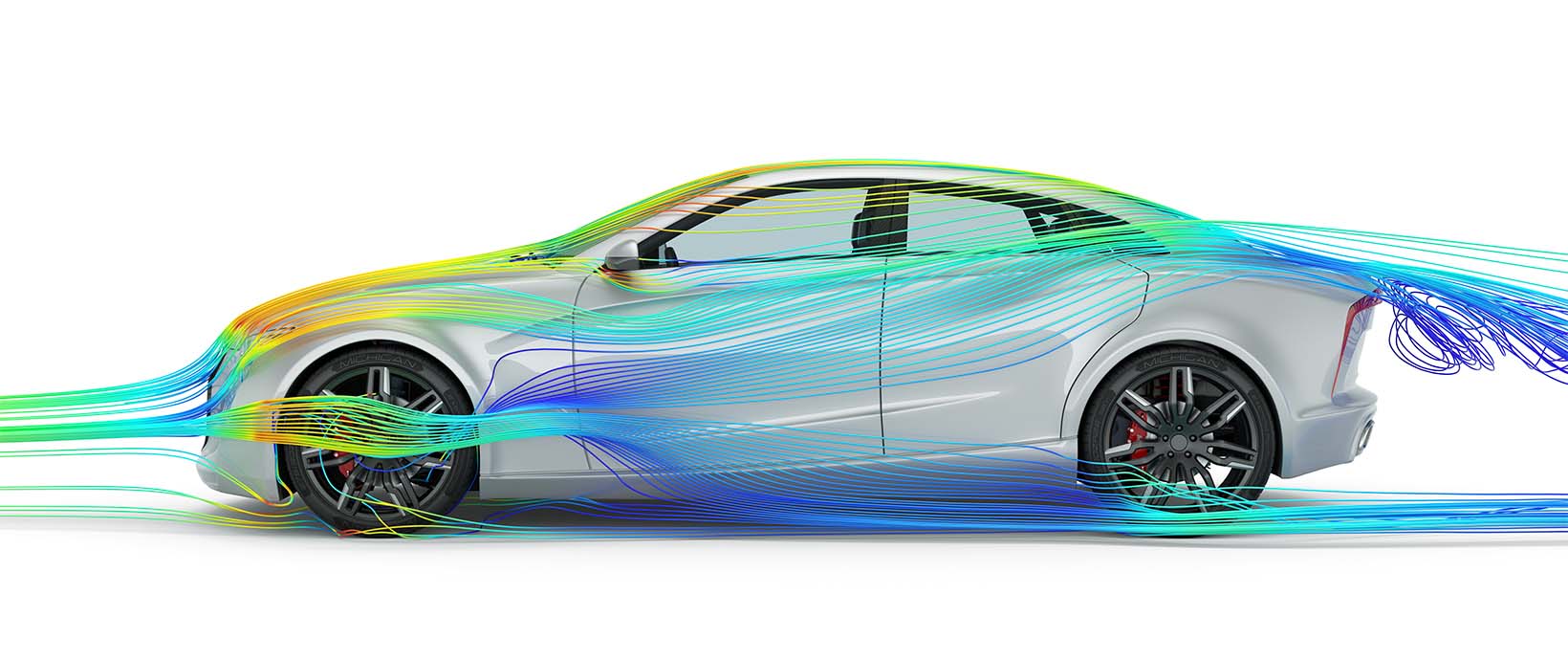

In the car industry, the same procedure was used to design a sound absorbing trim with specifications related to oil and gravel projections. From the optimization procedure, a foam and facing-screen couple has been identified. Commercially available products close to the optimized ones were identified and are now used in cars currently on the market.

https://www.youtube.com/watch?v=nTGymcIQwLA&feature=youtu.be

Learn more about MATLEYS and their solutions in the Altair Partner Alliance.

New Opportunities for Acoustics

New manufacturing techniques have led to new opportunities in the thinking of material design. Virtual prototyping and careful material screening lead to more efficient solutions at equal or reduced cost. At last, a quieter life may be considered.Our Methodology

At Matelys, we use a 3-step methodology to fulfill the requirement for better acoustics.First, the characterization of the intrinsic parameters of materials allows to identify the dissipation mechanisms governing the material responses. This can be done using measurements or computational approaches (based on e.g. micro-macro or virtual prototyping approaches).

Second, thanks to this knowledge, there is no need to work on complicated models. Simple geometries work better. The Transfer Matrix Method (TMM), a quick analytical technique as implemented in AlphaCell (available via the Altair Partner Alliance) is a more convenient technique than the Finite Element Method (FEM) to optimize the material arrangement.

Last but not least, it is important to capitalize on the acquired knowledge. Let's keep it simple for better customer usability. Web based smart tools are a good alternative to disseminate the results of the study and to let the team appropriate the results. As an illustration, the example below shows a modification of the strut thickness and simultaneous impact on the acoustic, elastic and thermal properties of the foam made of this strut morphology.

Applications

This three-step methodology has been applied in the domestic appliance industry, together with complementary innovative solutions, to design one of the quietest vacuum cleaners ever. The characterization allows the identification of the key parameters governing the acoustic behavior of the object.Foams, together with air-flow constraints, were identified to fulfill the sound absorption target. An optimization procedure relying on TMM simulations allowed the selection of the optimal material properties and the implementation of the optimized vacuum cleaner solutions.

In the car industry, the same procedure was used to design a sound absorbing trim with specifications related to oil and gravel projections. From the optimization procedure, a foam and facing-screen couple has been identified. Commercially available products close to the optimized ones were identified and are now used in cars currently on the market.

https://www.youtube.com/watch?v=nTGymcIQwLA&feature=youtu.be

Learn more about MATLEYS and their solutions in the Altair Partner Alliance.