The Key To Innovation Is In The Material

This guest post on Innovation Intelligence is written by Neil Baumann, Chief Operations Officer at Key to Metals AG, developer of the Total Materia materials database. Key to Metals is a member of the Altair Partner Alliance.

In the engineering domain, there is a continuous need to balance accurate, safe decisions with the blue sky thinking more akin to research and design, but is it possible for data providers to keep pace with this diverse requirement?

When done effectively, the provision of information about materials and their properties opens up countless possibilities for engineering decisions and can be a key fundamental facet of innovation within the business.

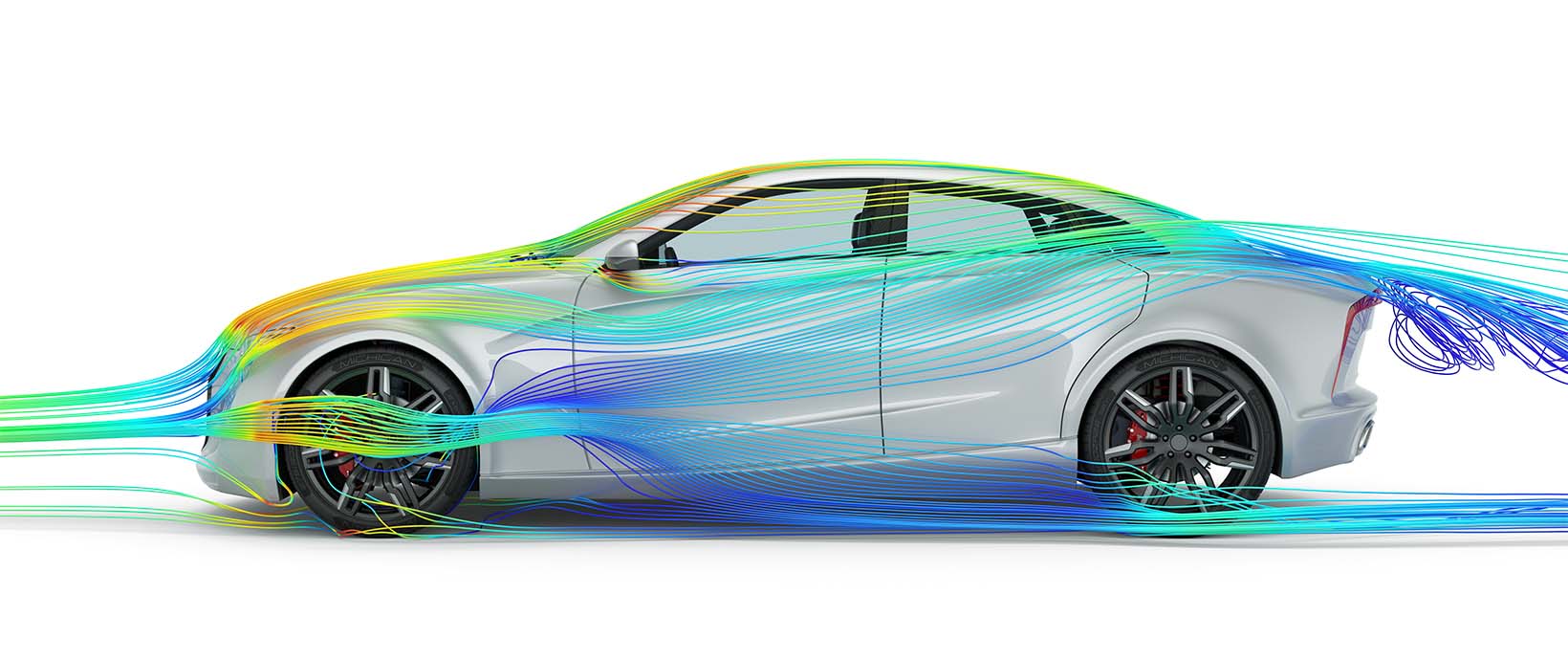

From the most basic challenges, such as which materials belong to which international standard, finding chemical composition or mechanical properties to solving much more complex problems by understanding plastic behavior at different temperatures or even enabling complex simulation scenarios to be assessed as part of business critical R&D projects, the need for material data is a constant.

Starting with the relatively simple concept of finding a specific property or properties for a known material, this raises some basic but important challenges. Different data sets for the same material cannot be freely found in one place, yield stress data could come from the material standard but stress strain curves will not. Modulus of elasticity can be found in a technical handbook but cyclic properties come from rare, experimental sources!

Along with the obvious laborious work associated with searching multiple sources for the data, there is also the critical question about reliability and accuracy which must be an absolute priority when considering overall associated risk and liability as well as best practice of material selection decisions.

Finding stress-strain curves provides a perfect example. It’s important not only to find a stress strain curve for a specific material but also to consider a number of other very important variables. The specimen will likely have a specific condition (i.e. hot rolled or solution annealed or many other possible delivery conditions) which will have a direct impact on the mechanical properties and therefore the performance of the material.

Figure 1: Stress strain curves taken from source and finally presented in the Total Materia Database.

Figure 1: Stress strain curves taken from source and finally presented in the Total Materia Database.

Now we have covered the first challenge, which is to provide data to satisfy the global engineering need – but how can this information be utilized to help with the really smart decisions? Finding data is one fundamental aspect to address but how can this huge pile of information (in the case of Total Materia we are talking about more than 260,000 materials and 7 million data points) be leveraged to help make the decisions that matter and assist in supporting the overall work flow?

Harnessing the power of all this information is vital, and whether it’s through cross referencing, comparison of materials or properties, allowing engineers to make rational decisions based on the relationships between materials and their properties in only seconds is an extremely powerful tool to have in the box.

To summarize, it is fair to say that it is not realistic to find a silver bullet which will answer all material questions a business might have for the huge diversity of decisions which need to be made every day, but supporting the workflow by providing comprehensive databases of information and intuitive ways to handle this information certainly is.

In the engineering domain, there is a continuous need to balance accurate, safe decisions with the blue sky thinking more akin to research and design, but is it possible for data providers to keep pace with this diverse requirement?

When done effectively, the provision of information about materials and their properties opens up countless possibilities for engineering decisions and can be a key fundamental facet of innovation within the business.

From the most basic challenges, such as which materials belong to which international standard, finding chemical composition or mechanical properties to solving much more complex problems by understanding plastic behavior at different temperatures or even enabling complex simulation scenarios to be assessed as part of business critical R&D projects, the need for material data is a constant.

Starting with the relatively simple concept of finding a specific property or properties for a known material, this raises some basic but important challenges. Different data sets for the same material cannot be freely found in one place, yield stress data could come from the material standard but stress strain curves will not. Modulus of elasticity can be found in a technical handbook but cyclic properties come from rare, experimental sources!

Along with the obvious laborious work associated with searching multiple sources for the data, there is also the critical question about reliability and accuracy which must be an absolute priority when considering overall associated risk and liability as well as best practice of material selection decisions.

Finding stress-strain curves provides a perfect example. It’s important not only to find a stress strain curve for a specific material but also to consider a number of other very important variables. The specimen will likely have a specific condition (i.e. hot rolled or solution annealed or many other possible delivery conditions) which will have a direct impact on the mechanical properties and therefore the performance of the material.

Figure 1: Stress strain curves taken from source and finally presented in the Total Materia Database.

Figure 1: Stress strain curves taken from source and finally presented in the Total Materia Database.Now we have covered the first challenge, which is to provide data to satisfy the global engineering need – but how can this information be utilized to help with the really smart decisions? Finding data is one fundamental aspect to address but how can this huge pile of information (in the case of Total Materia we are talking about more than 260,000 materials and 7 million data points) be leveraged to help make the decisions that matter and assist in supporting the overall work flow?

Harnessing the power of all this information is vital, and whether it’s through cross referencing, comparison of materials or properties, allowing engineers to make rational decisions based on the relationships between materials and their properties in only seconds is an extremely powerful tool to have in the box.

To summarize, it is fair to say that it is not realistic to find a silver bullet which will answer all material questions a business might have for the huge diversity of decisions which need to be made every day, but supporting the workflow by providing comprehensive databases of information and intuitive ways to handle this information certainly is.