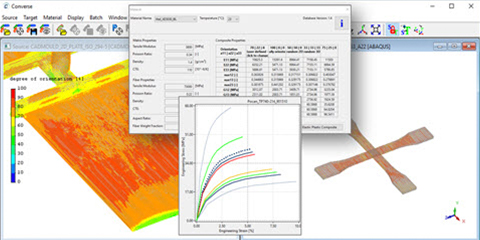

Converse by PART Engineering

Multiscale Simulation Software for Plastics

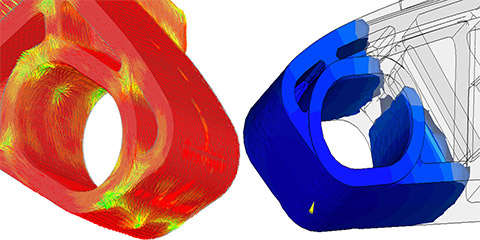

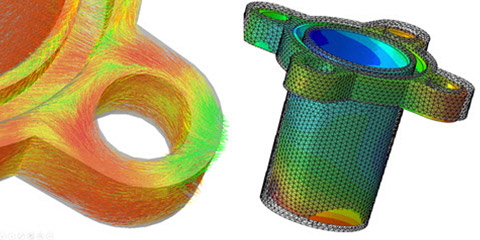

Converse is an easy-to-use software that bridges the gap between injection molding simulation and mechanical simulation. Converse has a variety of mapping capabilities including but not restricted to fiber orientation, weldlines, pressures, temperatures, thickness, and stresses. It exports the data in a ready-to-use FE input deck for the particularly supported solver and for the built-in material model of that solver.