Simulation, 3D Printing and Casting: The Perfect Symbiosis for Large Aerospace Structures

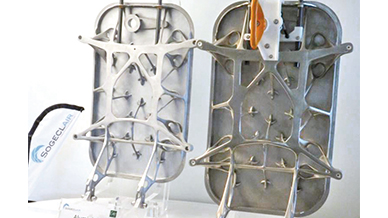

Additive manufacturing, commonly known as 3D printing, is increasingly raising interest, especially in the aerospace industry where reducing mass and hence fuel consumption is a major goal. Additive manufacturing offers huge potential since it enables the creation of load-specific organic shapes. Weight reduction as a result of mass removal and integration of multiple parts and functions within a structure lead to time reduction and much more. However, as a relatively new method in aeronautics, additive manufacturing suffers from certification and qualification issues where a lot remains to be done. Manufacturing capabilities are still restrained by the size of 3D printing machines, which makes the technology unsuitable for larger components within a plane, such as an engine pylon or an access door. The dimension issue is an obvious hurdle for 3D printing. An airplane door is, while being rather large – due to its complexity and function integration – a very promising part when it comes to potential cost reduction via a one-shot production method.

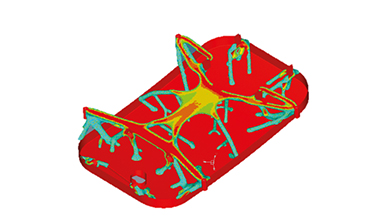

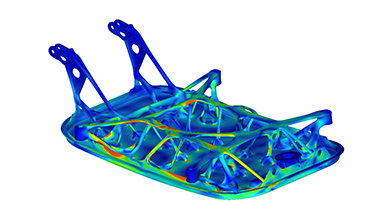

In a study, engineers from Sogeclair aerospace explored solutions for this problem by creating a development process combining the two methods of additive manufacturing and casting - their advantage to developing and manufacturing this airplane door. While casting is a 5,000 year old, well-validated process, additive manufacturing provides design freedom not currently offered by any other manufacturing method. To leverage the full potential of these combined methods, design and optimization of the door were handled using Altair’s HyperWorks™ software suite.

Simulation at SOGECLAIR

Sogeclair has been using Altair solutions for many years and relies heavily on the Altair HyperWorks software suite for simulation and development tasks. About 20 people regularly work with Altair tools, some of them in the innovation department at Sogeclair, which was responsible for the airplane door development.

The engineers use various Altair HyperWorks tools and rely heavily on Altair OptiStruct, an FEA solver and optimization tool, as well as Altair HyperMesh and Altair HyperView, which are applied for pre- and post-processing. OptiStruct is very much appreciated as an FEA solver and optimization software as it offers a series of interesting features to set up the optimization for the convergence of a satisfying solution. In addition to that, SOGECLAIR aerospace designers are working with Altair Inspire, the generative design/ topology optimization and rapid simulation solution, because it is easy to use and very valuable especially in the first design phase. SOGECLAIR aerospace uses all of the Altair tools via Altair’s flexible unit-based licensing system.