Altair® EEvision™

Smart Electrical System Visualization

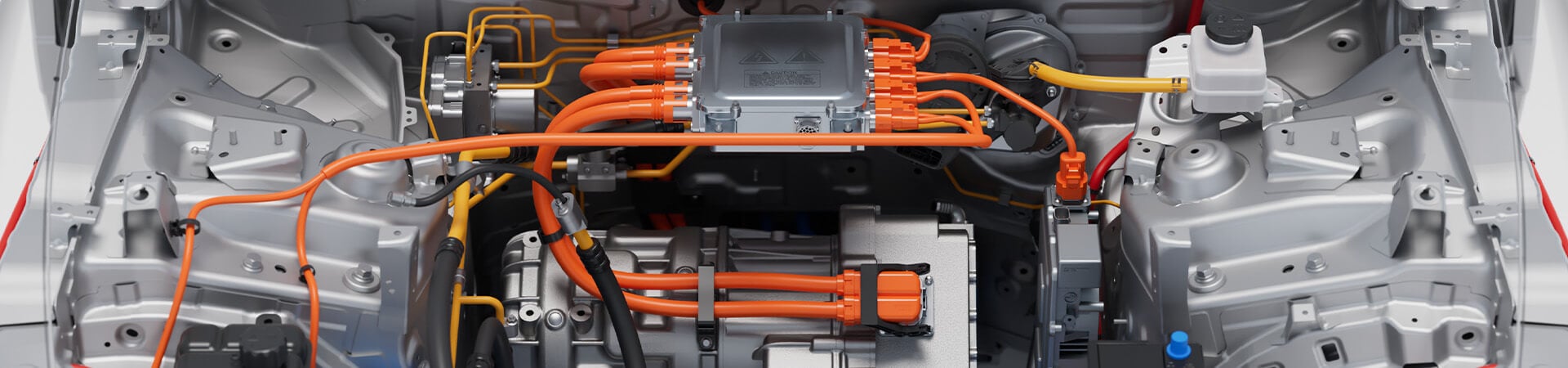

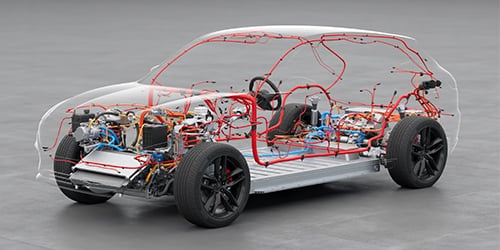

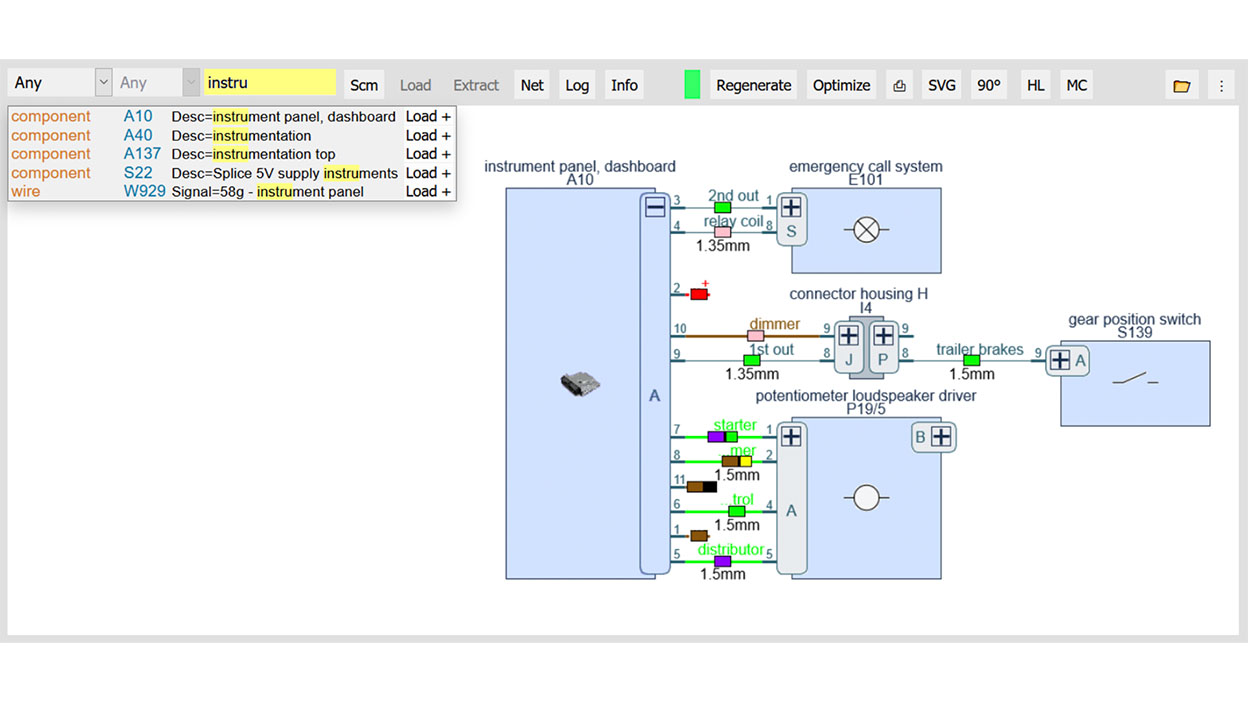

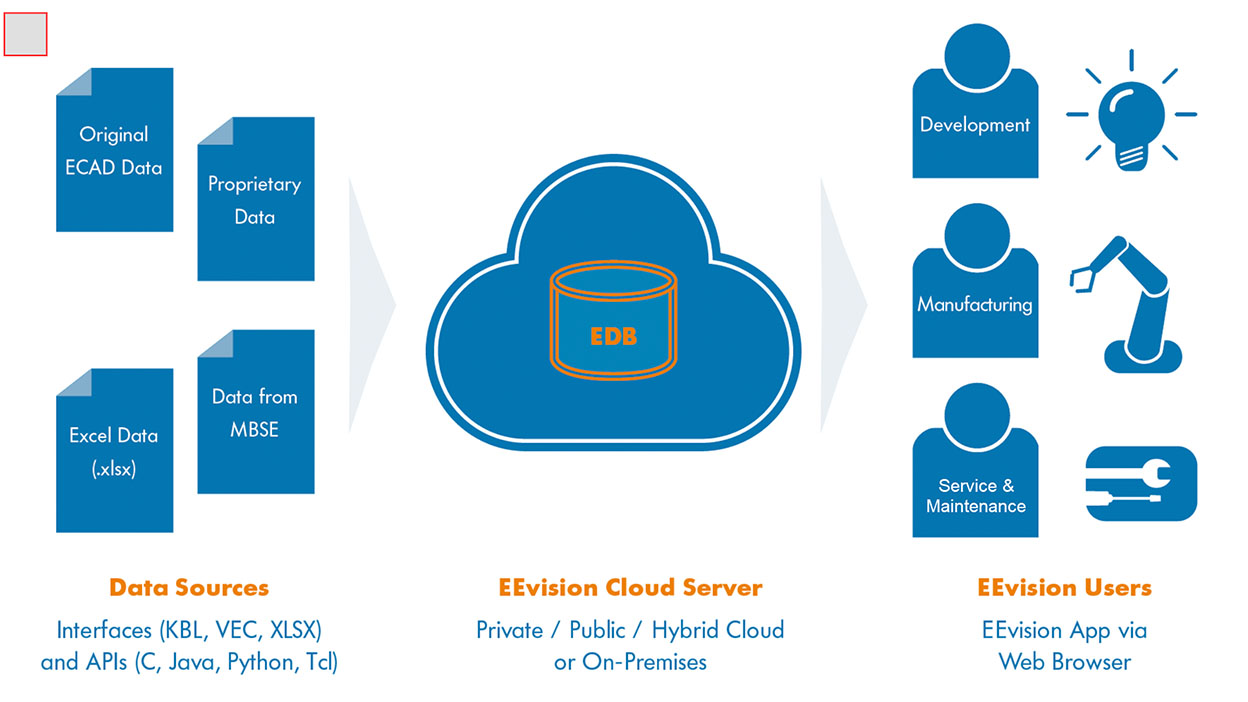

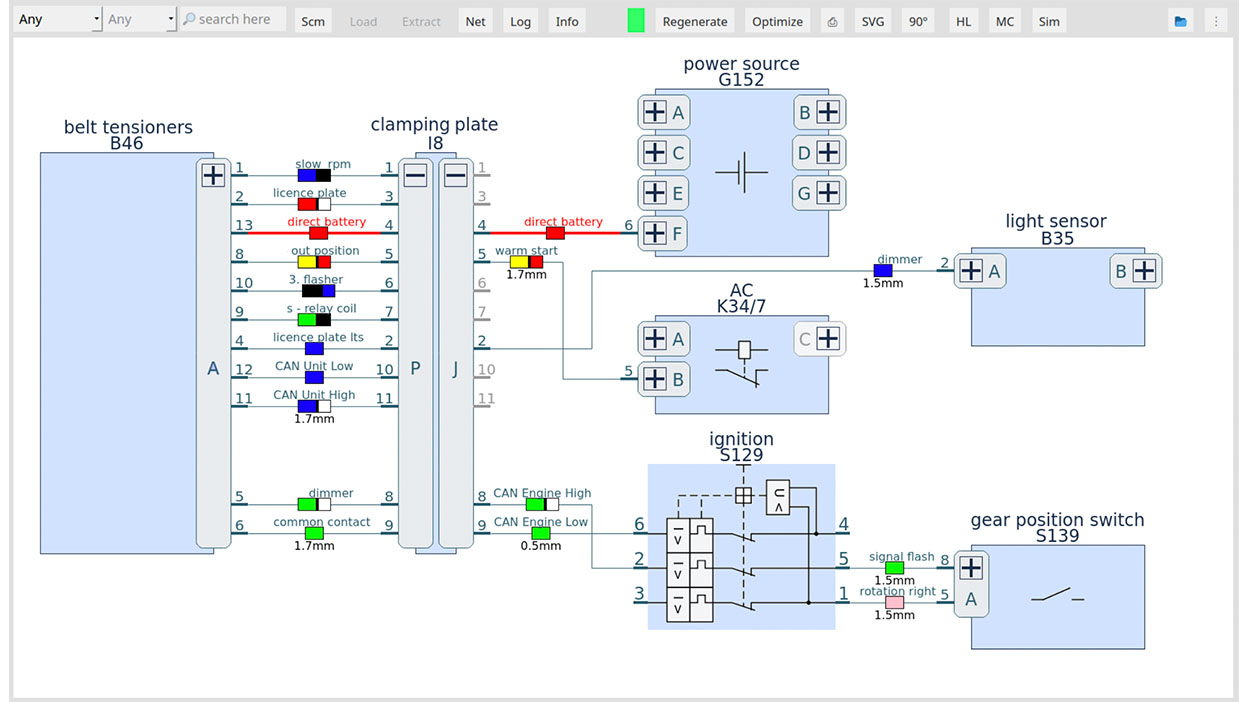

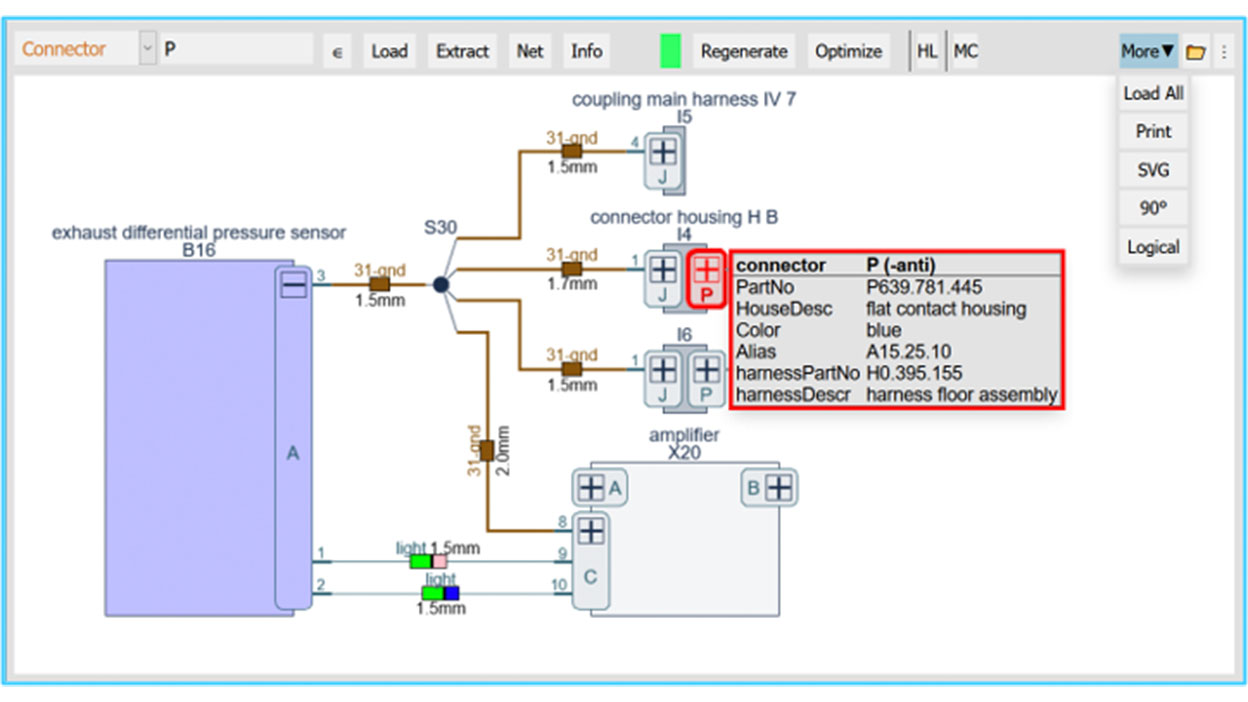

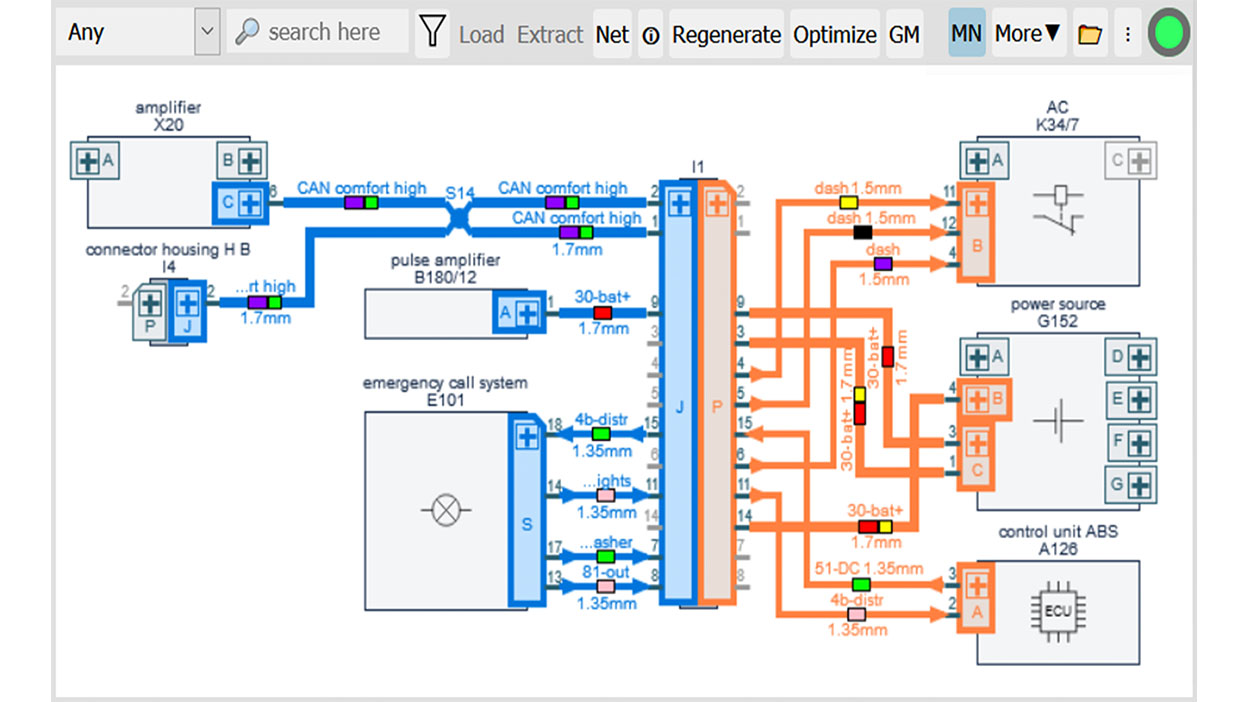

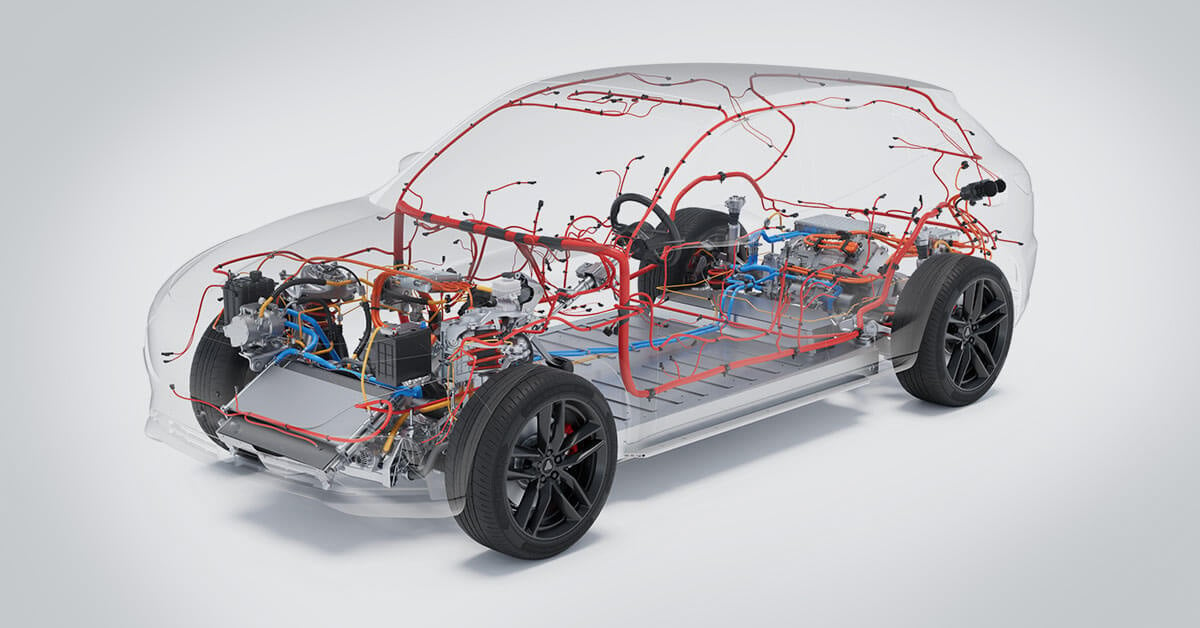

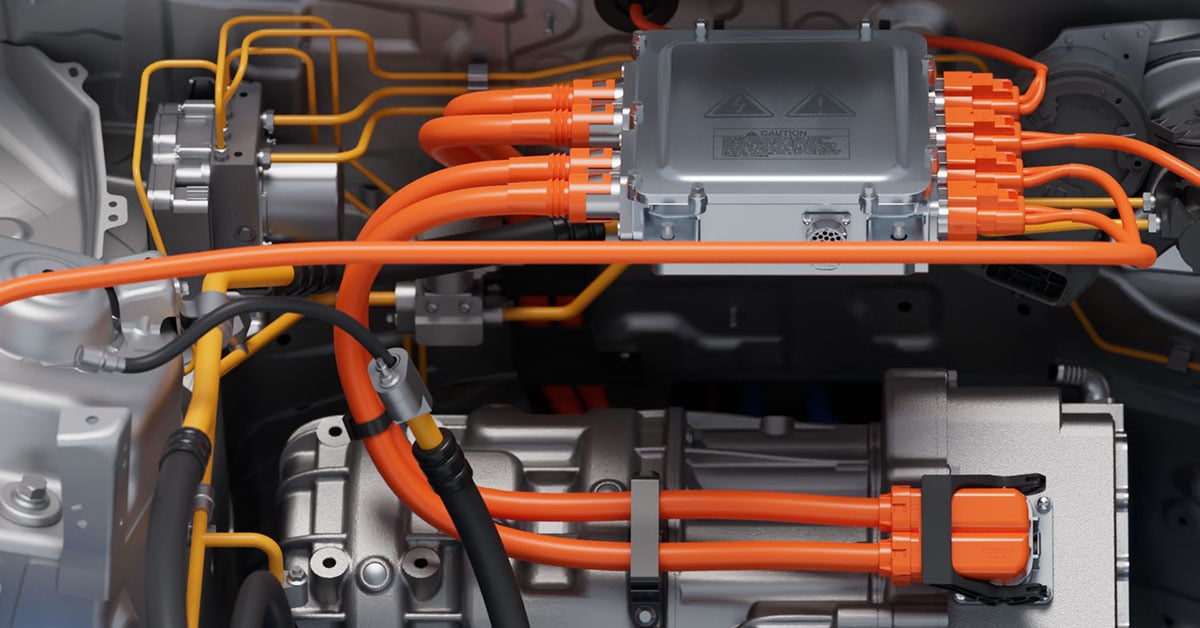

Electrical system complexity in modern automotive, aeronautical, and industrial electrical systems is accelerating. EEvision tames electrical system complexity by dynamically isolating and visualizing critical regions. System-rendered displays show up-to-date schematics for system connectivity, wiring harnesses, and component attributes to help development teams, manufacturing teams, and service operations quickly understand real-time critical information in complex electrical systems.

Digital twin model systems, generated using original ECAD data, proprietary data, or other standard formats, provide smart system visualization and automatic document creation. Users can extract precise information and display it in an easy-to-understand format with live searches that show electrical system functions and component influence, or drill down to specific component attributes linked to the digital twin model.