Morfeo by Cenaero

From Process Modeling to Integrity Analysis

Numerical tools can minimize the number of expensive trials needed during the optimization of a given process. Today, many companies use numerically simulated manufacturing techniques to experience their strategic advantages firsthand – enter Morfeo.

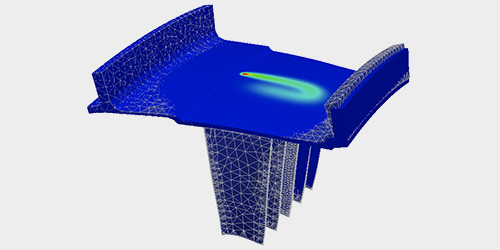

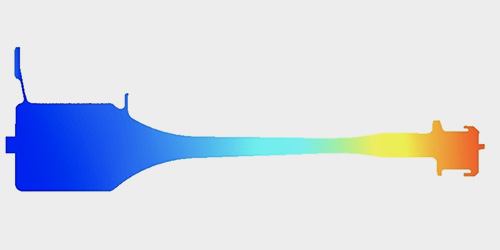

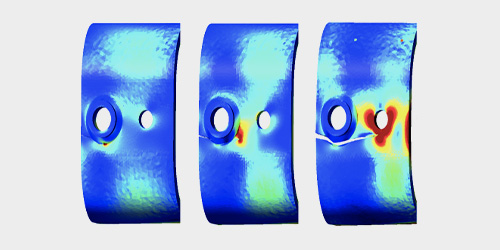

Morfeo is a modular, object-oriented finite element application. It relies on several dedicated libraries written in C++ for mesh management, mesh adaptation, material behavior, finite element features, solvers, and parallelism.

Morfeo

is dedicated to manufacturing process simulation (fusion and solid-state welding, machining, powder bed, additive manufacturing) and lifespan assessment (fracture mechanics, fatigue crack growth, damage).