Smart Products, IoT, and Digital Twins: What Do They Mean for Your Business?

Every product designer and engineer has seen these buzzwords a thousand times – smart products, Internet of Things, digital twin. They’re lauded as the future of product development, but it can be difficult to separate reality from hype. When trying to navigate the buzzword jungle, it’s critical to be able to answer the simple question of what these terms really mean, and most importantly, what they mean for your business.

In this article, we’ll try to demystify these terms and lay out the critical considerations needed before taking action.

What makes a product "smart?"

A smart product has built-in intelligence to read, adapt, and react to the operating environment in which it is used. Smart products have sensors to perceive their surroundings, and electronics, embedded code, and on-board systems to decipher the incoming signal from the sensors. Depending on the system design logic, sensor data is then stored locally or transmitted using the internet to and from the cloud. Finally, machine learning (ML) algorithms found either locally – on the edge as it is called – or on the cloud utilize this data to arrive at the appropriate action and trigger the actuators which execute the action. The data analytics also provide real-time visualization to the user and the product manufacturer through dashboards and alerts.

Smart product development process

Smart products bring a host of advantages, both to end users and product manufacturers. For end-customers, smarter products can dramatically improve user experience by bringing control, automation, and flexibility to the user’s fingertips as well as analytical insights for improving the performance and reducing the operating cost of products.

For the manufacturer, smart products enable data-driven product decisions which make operations more efficient, improve product quality and time-to-market, and enable timely support. Smart products are more future-proof and competitive, and they add the potential for recurring revenue streams.

Key elements of the operating environment of a smart product

For all their inherent benefits, the design of connected product does require a different mindset. All design decisions need to factor in the ability of the product to connect and communicate online, as well as account for limited or total autonomy that intelligence can bring to it. Also to be considered is the flexibility and scalability that comes with the IoT system connecting thousands of such devices, and how the product needs to perform in such a connected environment.

The decision of where you should put sensors to collect data, how the device will connect to the internet, and how you will digest field data can heavily influence multiple aspects of the product design and development process as well as the in-service operation. Additionally, organizations need to consider whether device connection is secure and reliable, how they will update firmware, and how the product will work in a larger network of assets.

What really is the Internet of Things?

The term “Internet of Things” was first coined in the 1980’s but has gained significant traction over the last 10 years. It defines a series of physical objects (cars, refrigerators, phones, smart watches, etc.), or “things,” that are connected and able to collect and exchange data. Sensors and actuators embedded allow the devices to communicate with each other and collect data about themselves. The Internet of Things is a network of connected devices and gateways constantly collecting and sending data.

While the jury is still out over whether consumers see value in having a “smart refrigerator” ordering milk when it finds the stock running low, matters are quite different for a manager in an industrial facility. Data collected in a factory environment can lead to more efficient processes and offer forecasts on maintenance intervals, the remaining lifespan of an equipment, or its functional safety. Specialized high value “smart” equipment and assets can further gain in terms of increased lifetime, improved operational efficiency, and provide insights that lead to better next gen versions.

Creating an IoT-enabled smart product is more than just connecting to an out-of-the-box IoT platform.

While many companies have a connected product vision, few have everything it takes to quickly and securely develop scalable software to move their product from disconnected to connected.

Companies looking to take advantage of the Internet of Things need software tools to scale up quickly and stay secure. It starts with reliable and secure device communication technology, including remote device provisioning and management. Edge compute and orchestration platforms are a must to decide if, how, and when to transfer what data between products and the cloud. Finally, data storage, stream processing, real-time data visualization, and ML tools complete the IoT system that makes the connected product operating efficiently and maximizing the value derived therefrom.

IoT device management, access control, and security

Connected devices must have robust security to protect the manufacturer’s valuable data, but above all, the private data of its users. Companies need to establish system-level oversight, using automatic container scans and other monitoring tools to detect security issues and ensure multitenancy security. Additionally, fine grained access control is needed to identify and correct issues at the individual device level. Internal communication between platform components should also be encrypted to provide an additional layer of security.

What role does CAE play towards building a true digital twin?

The phrase “digital twin” has become quite the buzzword, stirring up utopian views on what it can do for predictive maintenance, simulation, product development, and more. But how is it different from a 3D CAD product model? Can it ever live up to its full potential?

As the name suggests, a digital twin is a digital representation of a physical object or system. It is typically connected to the physical asset with sensors, enabling two-way communication. The popularity of digital twins is on the rise because they provide organizations with a wide range of benefits.

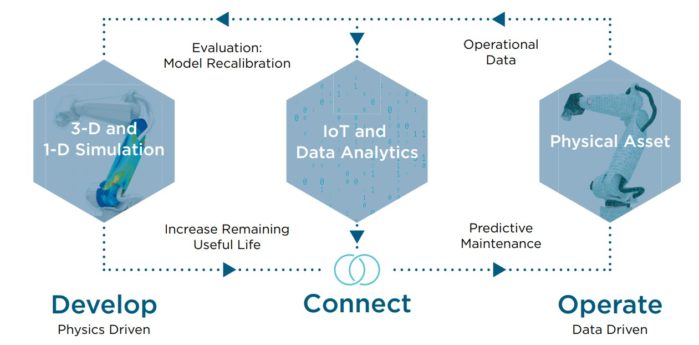

A digital twin requires a physical asset which can be connected to extract real-time or near real-time data. The data can then be pumped into either a physics driven simulation model or a data analytics model to provide solutions like predictive maintenance or predictions of asset performance, efficiency, and remaining useful life. With a connection to a physical device, CAE models move beyond virtual prototype validation, leveraging real-world data instead for simulation and thereby derive more accurate insights on the product performance. With a true digital twin, designers can also examine the impact design changes may have on system performance and predict how complex products will perform over time.

A CAE-based physics-driven digital twin leverages a combination of 1D and 3D simulations to create comprehensive virtual models to examine system-level performance. High-fidelity physics models can be simplified for system simulation using reduced order modelling (ROM). By reducing the complexity of a 3D model, engineers can quickly study system performance with minimal computational resources. Where more detail is needed in the system model, The functional mock-up interface (FMI) provides a standardized method for exchanging dynamic simulation models. Simulation models are packaged as functional mock-up units (FMU), which easily integrate into most major simulation packages.

Workflow connecting physical asset, simulation-driven and data-driven digital twin

So how do I get started?

Smart products, the Internet of Things, and digital twins have already begun to transform the way companies do business. New product lines, recurring revenue streams, more efficient operations, higher quality, and faster time-to-market are all within reach with the introduction of smart interconnections between systems and assets. Altair has the knowledge and technology to help you realize your smart product development vision from beginning to end – from ideation, to optimization, to launch and operation.

To learn more about designing an IoT strategy and effectively connecting your smart devices at scale, download the Guide to Smart Product Development: Making the Internet of Things Work for Your Business.