Smart Simulation of Hydraulic and Pneumatic Systems

This post on Innovation Intelligence was written by Dr. Heiko Baum, owner of FLUIDON GmbH, developer of fluid power simulation software DSHplus. FLUIDON is a member of the Altair Partner Alliance.

Hydraulic systems and components are fundamental building blocks for state-of-the-art technology in the automotive, aerospace, naval, and energy sectors. Whether you consider hydraulic dumpers, hydraulically driven floors, hydraulic accumulators, hydraulic actuators or hydraulic hoses, modern hydraulic systems are typically subject to extreme requirements in terms of reliability and frequency of use. In addition, hydraulic systems are typically integrated into complex larger systems with multiple interactions.

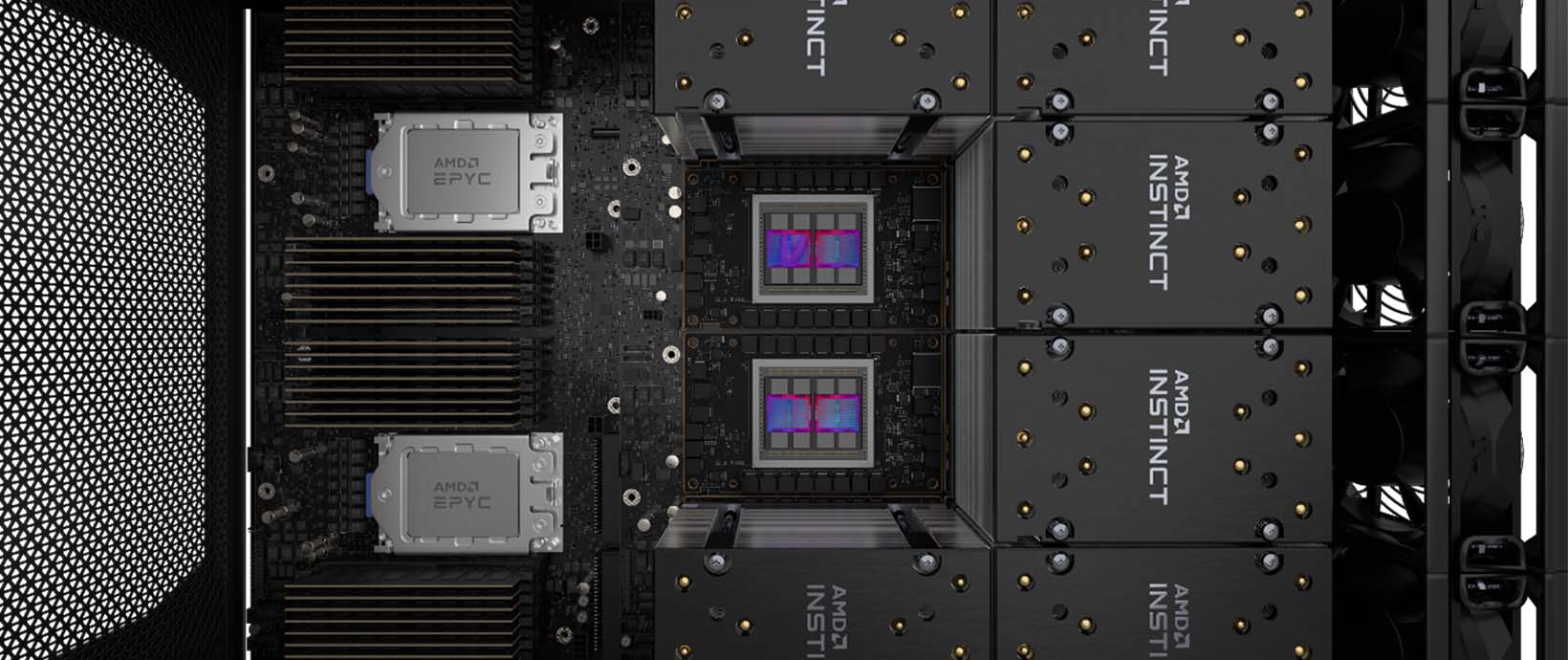

Due to higher expectations with respect to realism and calculation accuracy in simulation-based development, a detailed consideration of the interactions of various technical sub-systems becomes more and more necessary. A computer-based system development approach using specialized computer-aided engineering (CAE) tools provides a detailed understanding of hydraulic systems and their integration requirements. By coupling programs from different technical domains and with different specific strengths, it is possible to take advantage of all the software tools used within a simulation framework.

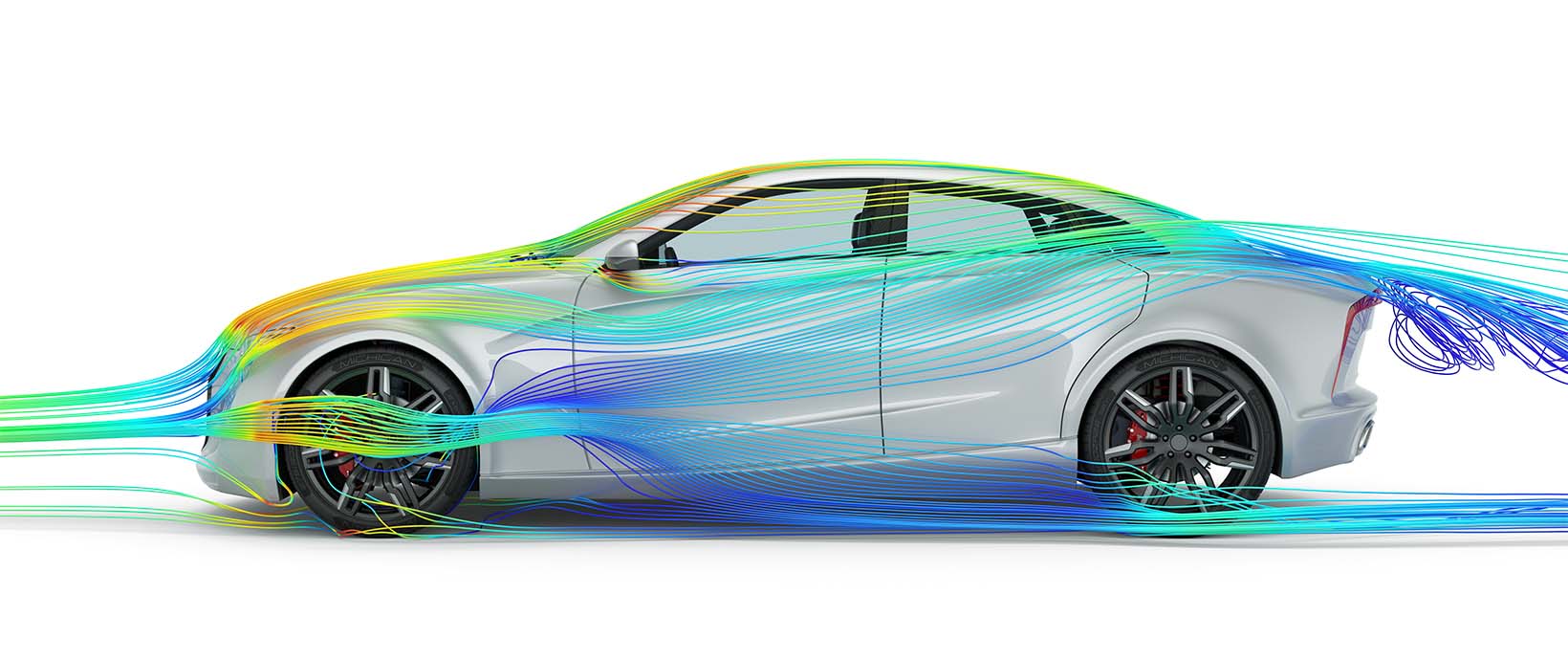

This co-simulation primarily focuses on the coupling of three-dimensional multibody dynamics (MBD), computational fluid dynamics (CFD), control engineering tools, and non-commercial programs for special areas, such as tribological simulation tools. Some advantages of software couplings are obvious, such as enabling the mechanics of a system to be modeled one-to-one within a 3D-MBD program. This would include all boundary conditions, flexible structures, and accurate physical component properties and would not have to be approximated by 1D mass-spring-damper systems or look-up table-based load cycles.

The hydraulics of a system, on the other hand, may be modeled in detail within DSHplus and coupled to the MBD program via defined interfaces. As a result, the strengths and the full functionality of all programs could be used, resulting in an accurate mechanical simulation as well as a detailed hydraulic simulation.

Hydraulic systems and components are fundamental building blocks for state-of-the-art technology in the automotive, aerospace, naval, and energy sectors. Whether you consider hydraulic dumpers, hydraulically driven floors, hydraulic accumulators, hydraulic actuators or hydraulic hoses, modern hydraulic systems are typically subject to extreme requirements in terms of reliability and frequency of use. In addition, hydraulic systems are typically integrated into complex larger systems with multiple interactions.

Due to higher expectations with respect to realism and calculation accuracy in simulation-based development, a detailed consideration of the interactions of various technical sub-systems becomes more and more necessary. A computer-based system development approach using specialized computer-aided engineering (CAE) tools provides a detailed understanding of hydraulic systems and their integration requirements. By coupling programs from different technical domains and with different specific strengths, it is possible to take advantage of all the software tools used within a simulation framework.

This co-simulation primarily focuses on the coupling of three-dimensional multibody dynamics (MBD), computational fluid dynamics (CFD), control engineering tools, and non-commercial programs for special areas, such as tribological simulation tools. Some advantages of software couplings are obvious, such as enabling the mechanics of a system to be modeled one-to-one within a 3D-MBD program. This would include all boundary conditions, flexible structures, and accurate physical component properties and would not have to be approximated by 1D mass-spring-damper systems or look-up table-based load cycles.

The hydraulics of a system, on the other hand, may be modeled in detail within DSHplus and coupled to the MBD program via defined interfaces. As a result, the strengths and the full functionality of all programs could be used, resulting in an accurate mechanical simulation as well as a detailed hydraulic simulation.