World’s Leading NVH Simulation Partner

Our NVH solutions automate analysis tasks to reduce lead time, deliver NVH performance with attribute balancing, predict and eradicate squeak and rattle phenomena, and eliminate expensive late design changes; all backed by a dedicated team of NVH experts across the globe.

Let us show you how.

Contact UsGlobal Expertise

Computer aided engineering and simulation technologies (CAE) are widely recognized as an essential part of the NVH design process. However, methods, procedures, and industry best practices must be continually reviewed and developed if design and business challenges are to be met. This is where our NVH consulting team can help.

Leverage Global Best Practices

Our NVH consultants are veteran industry experts from leading OEMs and have a proven history in delivering best in class NVH performance. Our team routinely helps companies develop products and methods, encompassing global best practices for benchmarking, target setting, modeling and load cases that enable true, upfront design and problem solving.

Enhancing NVH Performance

Simulations that include more physical effects take account real world variability and allow noise and vibration to be experienced subjectively. Industry trends are followed closely, such as the increase in electric and hybrid vehicles and the lightweighting of engines. Specific approaches are developed to meet these challenges and deliver leading NVH performance.

Reducing Lead Times

We lead the world in structural optimization techniques, and have done so for more than 20 years. Leveraging our optimization technologies and expertise, in conjunction with NVH analysis and diagnostic capabilities, we can help your team find the optimal design fast, significantly reducing development lead times.

Explore More with Simulation

The Altair® HyperWorks® simulation suite contains a broad range of solutions for NVH model build, assembly, diagnostics, analysis and optimization; all designed to reduce the simulation cycle time and allow CAE engineers to focus on performance enhancement at component, system, and full vehicle levels.

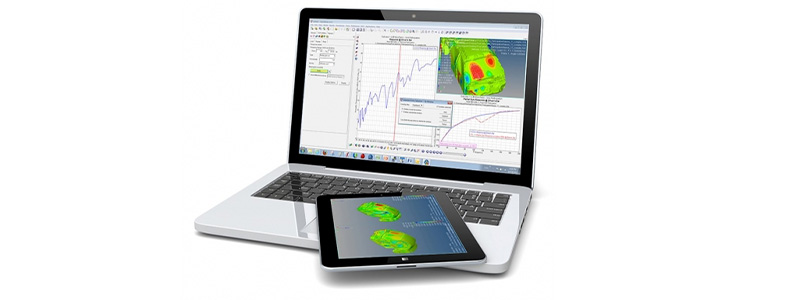

Automating NVH Analysis

NVH Director employs the HyperWorks suite of computer-aided engineering (CAE) tools in a fully integrated, user-friendly, customizable form to automate the tasks involved in NVH analysis. By integrating the entire process of meshing, assembly, loadcase setup, and post-processing, it dramatically reduces the full-vehicle NVH simulation time, freeing CAE engineers to focus on optimizing product design and performance.

Optimizing NVH Performance

Altair® OptiStruct® - Altair’s structural solver for linear and nonlinear analysis - provides unique and advanced functionalities for NVH analysis and optimization, including Auto–TPA analysis, a large scale Eigen solver (AMSES), several model reduction techniques, design sensitivities, and ERP response, which makes it easy to optimize structures for NVH performance.

“With OptiStruct, it is now possible to run larger, full vehicle NVH models for more accuracy without the errors generated by our existing NVH solver on the same computer.”

- SsangYong Motors

Eliminate Squeak and Rattle Noise

Silence has become synonymous with quality; and with the advent of electric vehicles, we can no longer rely on the engine to mask undesirable noise. Physical testing provides a solution, but costs are high and design input is given late in the development process. Our simulation based approach provides an alternative approach.

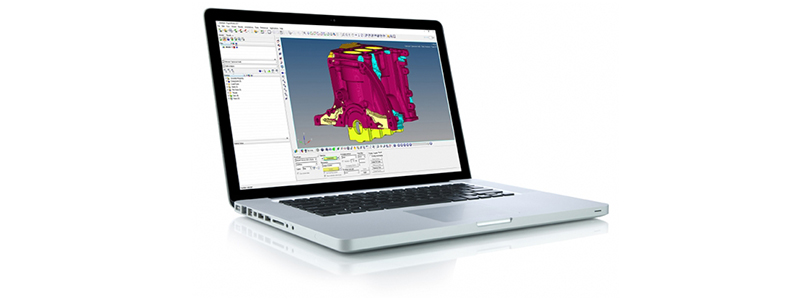

Squeak and Rattle Director

Altair® Squeak and Rattle Director™ is a novel set of software automations that rapidly identify and analyze design alternatives to eliminate the root causes of squeak and rattle (S&R) in assemblies. Tailored to be deeply integrated within your environment and processes, SnRD offers a complete set of capabilities to streamline the entire S&R simulation workflow process from model creation to results visualization.

Collaboration at Our Core

We partner with companies throughout the NVH world, leveraging their techniques and technologies to help streamline the NVH analysis process for our clients.

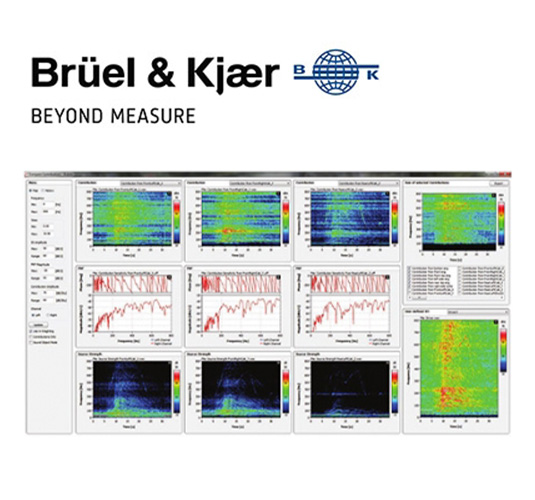

Integrated Test & Simulation Services

Integrating physical test data with simulation and analysis results can accelerate development programs while improving vehicle NVH performance. We are working closely with sound and vibration specialists, Brüel & Kjær, to combine simulation and physical test data into the company's range of vehicle simulators. Together we are coupling Brüel & Kjær's Insight+ technology with our own NVH Director to provide holistic solutions from physical test to simulation, optimization and visualization of NVH results.

Tire Modeling & Analysis Solutions

Tires are an extremely difficult component to model accurately within an NVH model, but their impact on NVH performance can be significant. We work with research and technology company, Fraunhofer, to integrate its CDTire tire model family with our NVH Director. Together, our solutions allow you to represent tire belts, sidewalls and treads, perform modal analysis, balance accuracy, and optimize performance.

Extensive Materials Database

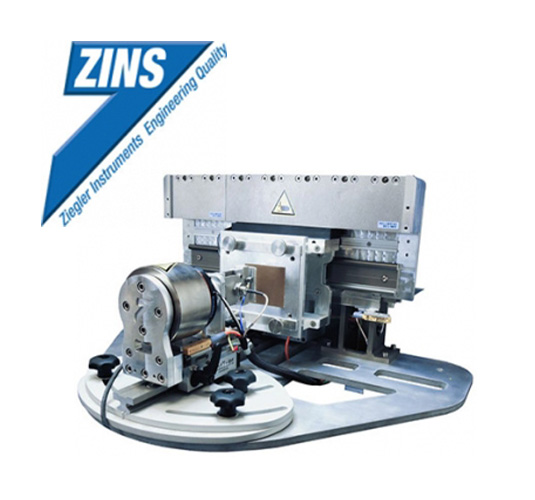

ZINS Ziegler Instruments has collected its extensive knowledge of material into its leading Precise Expert Materials (PEM) database which consists of over 6,000 individual measurements, all designed to help manufacturers choose material pairs to avoid squeak and rattle noise. Altair works with ZINS to enhance the Squeak and Rattle Director with high quality materials data to enhance simulation accuracy.