QSD® by Cetim

Easy-to-use Design Optimization Workflow

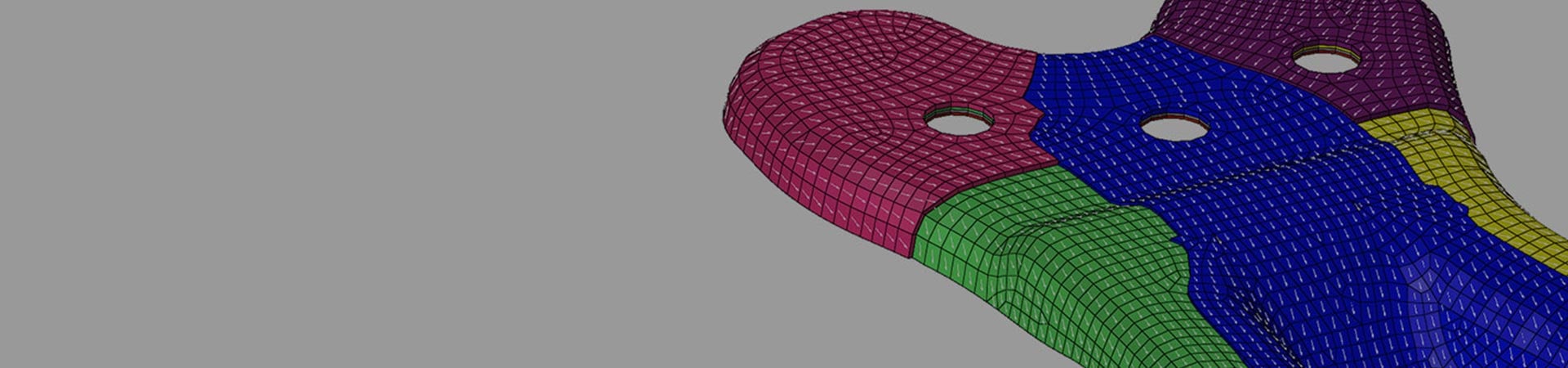

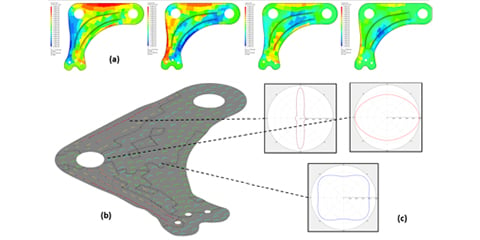

Quilted Stratum Design (QSD) offers an intuitive workflow in the Altair® HyperMesh® environment that leads the designers to a smart composite design with adapted fiber orientation and reduced material scraps, thanks to draping analysis. The process know-how integrated in the optimization, allows for considering the minimization of part cost as an objective for the final choice of material and lay-up. QSD aims at designing efficient structural parts manufactured from hot-pressed, multi thickness preforms of thermoplastic plies. Nonetheless, the QSD method fits with all process creating "tailored preform" (tape placement, QSP, hand lay-up, etc.).

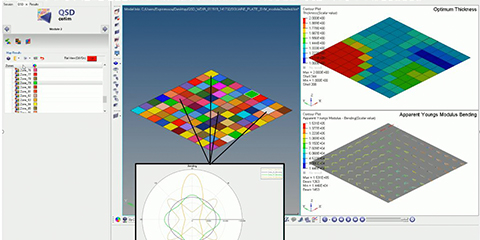

QSD has been developed by Cetim and Altair, from research results of ONERA, which has created a multi-step optimization method that reduces calculation time but maximizes the field of solution. This "stiffness matching" method is the ideal target for mechanical performance, then the lay-up to achieve it, according to the possibility of your process.

With QSD, the designer knows the ideal thickness and fiber orientation for its composite shell. Then QSD will cluster zone to propose ply shape and definition that match with the ideal target. The designer may evaluate various laying strategies and compare their cost and performance.