Digital Twin of Crop Harvesting System using Altair EDEM

Dr. Mehari Tekeste, Associate Professor, Director, Soil Machine Dynamics Laboratory at Iowa State University presents at the 2024 ATCx DEM.

Creating a virtual representation that serves as the real-time digital counterpart of grain biomass using the Discrete Element Method (DEM) and Computational Fluid Dynamics (CFD) techniques provides a promising methodology to predict mechanical and pneumatic fractionation of Whole-Plant-Corn (WPC) particles for food and biomass energy production. Applying digital twins and multi-physics coupling of DEM & CFD allows for accelerated design analysis of mechanical and pneumatic machine systems for energy-efficient value-added biomass fractionation.

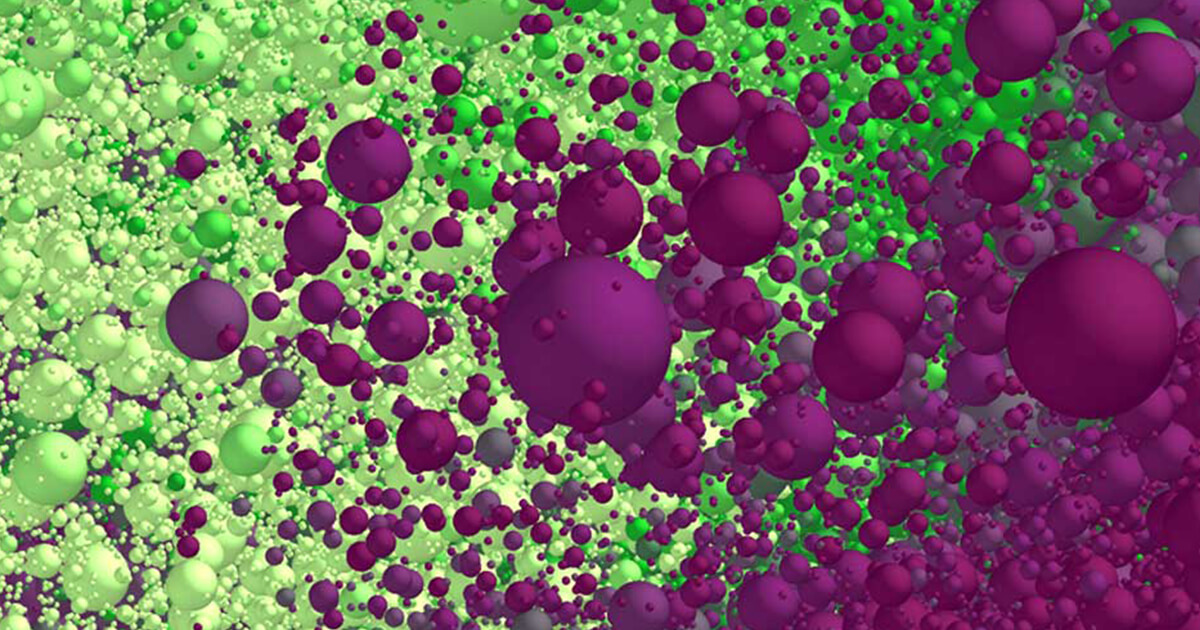

Complex shapes of WPC particles (kernel, husk, and stalk) were modeled in Altair EDEM using spherical and cuboid primate shapes after applying Gaussian multivariate regression and bootstrap sampling from axial dimension data of WPC particles. Applying meta-model regression and inverse optimization techniques, DEM predicted the mass percent of the WPC anatomical fractions at a 3% mean percent relative error compared to ASABE standard mechanical sieving data. Using Altair EDEM - Altair AcuSolve multi-physics modeling of vertical wind tunnel and ¼ scaled cleaning shoe systems, pneumatic separation efficiencies of kernel, husk, and stalk were successfully predicted with a mean percent relative error of 15%. Using spherical and cuboid EDEM approximates and systematic calibration of WPC particles, DEM-CFD modeling techniques simulated WPC materials' mechanical and pneumatic fractionation, enhancing the development of digital twins of crop-harvesting processes.