Predicting Compression and Impact Damage in Cereal Grains using DEM

Dr. Kingsly Ambrose, Professor at Purdue University presents at the 2024 ATCx DEM.

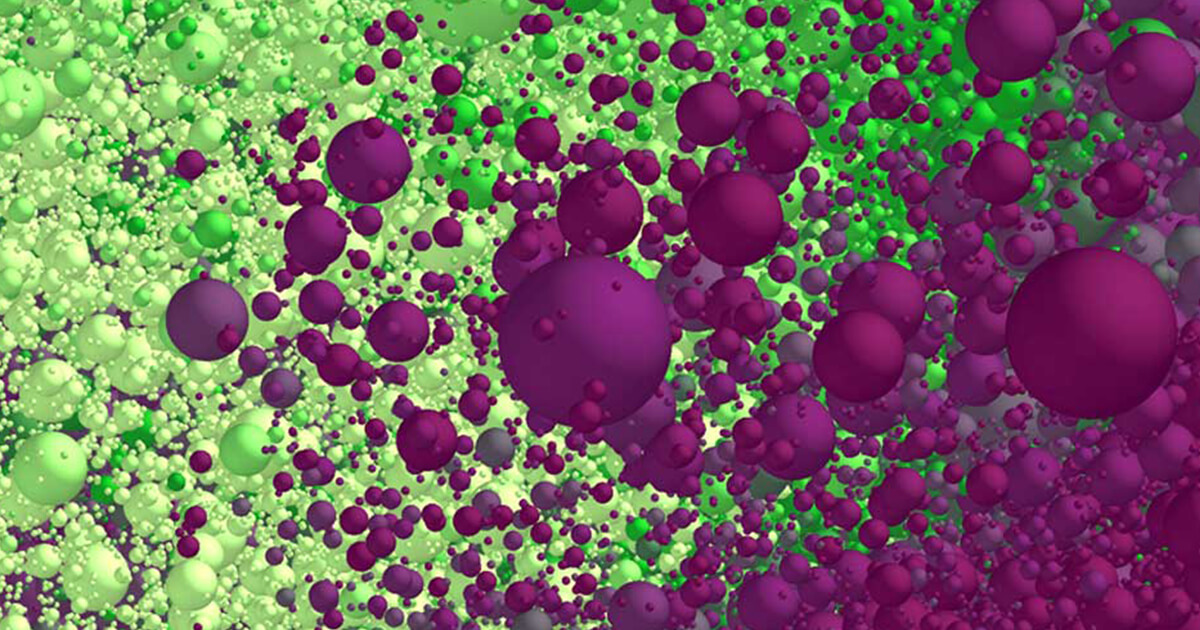

Impact and compression are the major sources of grain kernel damage during harvesting and handling. For instance, grain kernels are subject to excessive impact load when being threshed inside a combine harvester, being transported inside a pneumatic conveyor, and being unloaded and falling onto a hard surface from a significant height. Grain kernel damage models were developed and validated to predict damage, to help optimize design and operation settings of agricultural equipment and, thus, reduce grain loss and improve grain quality. The damage probability of grain kernels was modeled as a three-parameter Weibull function of mass-specific impact energy. A modified Wisconsin breakage tester was used to measure the model parameters. The developed damage models were then incorporated in Discrete Element Method (DEM) software and was validated in a Stein breakage tester. DEM simulation was able to give a good prediction on the percentage of damaged corn kernels with a low root-mean-square deviation between the experimental and simulation results. In addition, a sensitivity analysis indicated that particle shape, coefficients of restitution, and damage resistance parameters had a significant effect on simulated damage fraction.