Real-life Applications of Drivetrain CFD

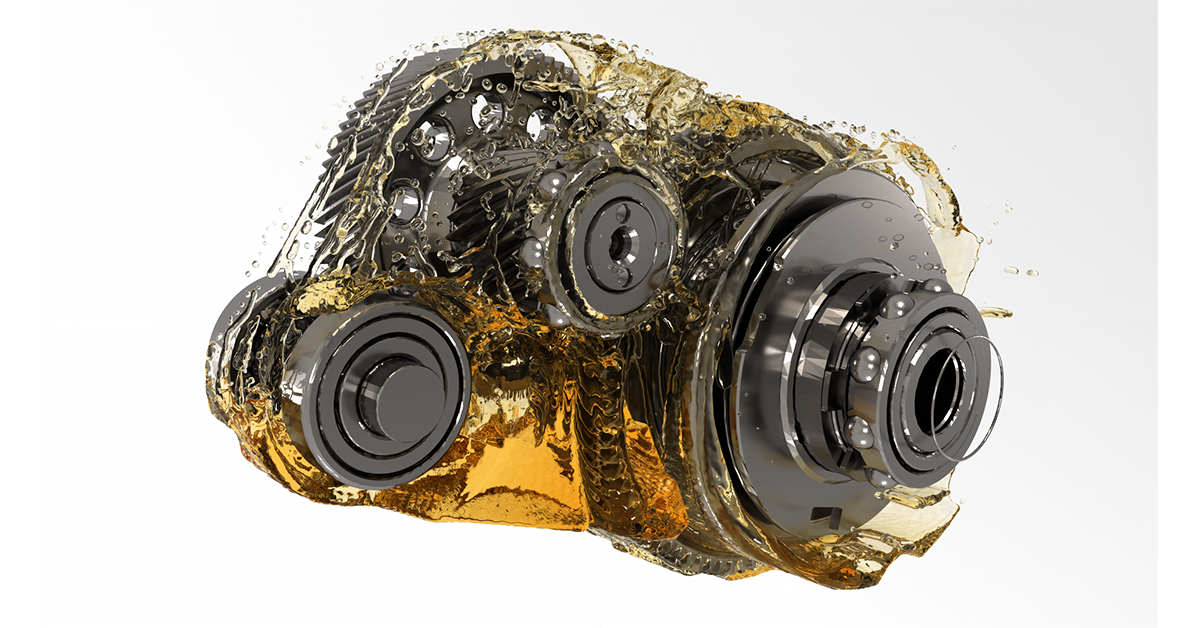

Accelerate Your Drivetrain Design Process with SPH Technology

While the topic of efficient drivetrain oil management has been a long-standing engineering problem, significant improvements in simulation of such components and physics has only recently become plausible in an industrial environment. Classic (Eulerian) CFD methods were too cumbersome to fit into the fast-paced modern design process of drivetrain components. The SPH (Lagrangian; particle-based) method shows a number of advantages in this arena of application, but is often misunderstood in terms of purpose.

In this webinar you will learn how to correctly use SPH technology in your drivetrain design process. Presenters will also provide a basic demonstration of SPH technology capabilities, followed by a real-life industrial example of use and validation. Dr. Milos Stanic of Altair will discuss particle-based CFD in the electric vehicle drivetrain component design process. Specifically, he will start with a high-level overview of how nanoFluidX can be used in the design process and end with an overview of capabilities and examples. Dr. Robert Johansson of CEVT will discuss electric drivetrain activities and how nanoFluidX capabilities were leveraged in the process.