Technical Development of Discrete Element Method for Plant-Scale Kiln Simulation

Dr. Motoaki Saruwatari I Chief Researcher, Technology Div, CAE Dept, Sumitomo Metal Mining Co., Ltd.

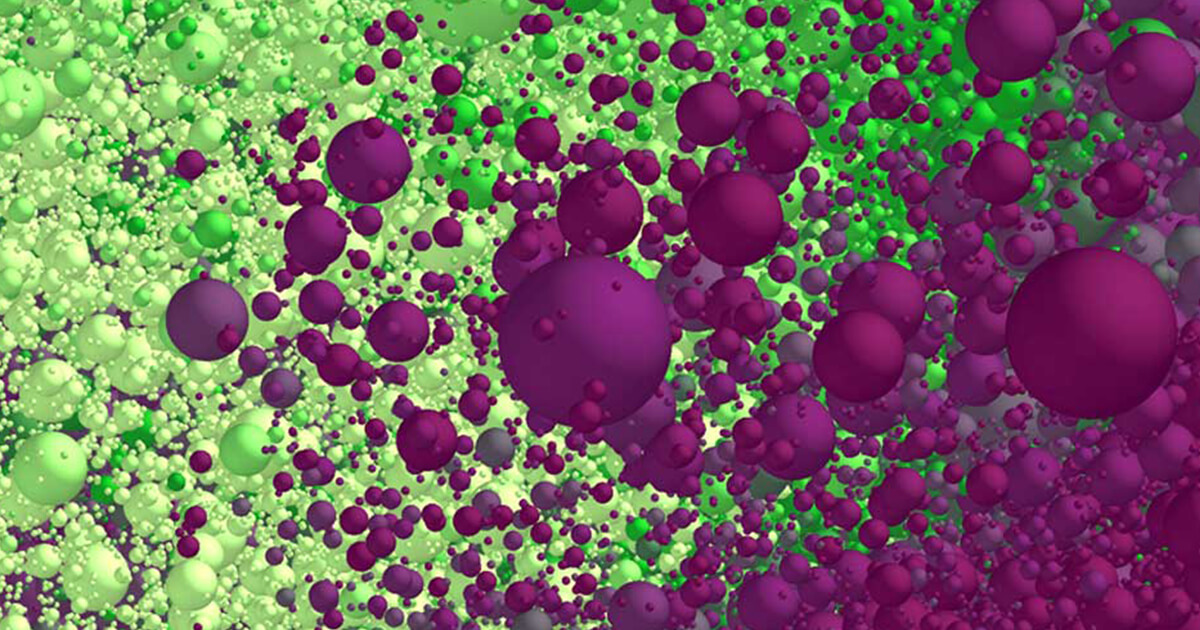

Rotary kilns are widely utilized in industrial applications, particularly for heat treatment processes. Due to the high temperatures inside a rotary kiln, it is difficult to understand the behavior of the materials within it. Recently, the Discrete Element Method (DEM) has enabled the calculation of powder movement. However the industrial rotary kilns are typically large, the materials stay inside the kiln for a long time. Therefore, comprehending the movement of materials throughout the entire kiln requires long computation times, which is a heavy computational load. In this study, to address this issue, we proposed a coarse-grained model to reduce the computational load and a model to predict the residence time distribution of the materials.