Altair® romAI™ Applications

Altair® romAI™ is a versatile and robust artificial-intelligence (AI) powered technology within Altair® Twin Activate™. An indispensable asset to your model-based development workflows, romAI serves many applications: digital twin creation and deployment; faster optimization and multidisciplinary analysis; model-order reduction; test-data processing for system identification; and better simulation accuracy.

The solution supports popular formats including Functional Mock-up Interface (FMI) standard, C code, and dynamic link library (DLL) for exporting to third-party software or hardware-based applications. When used for handling dynamic problems, romAI generates continuous-time dynamic models and works with any solver at any timestep.

Learn More about romAIromAI Customer Testimonials

Meeting Sustainability Goals

Mabe leveraged romAI to generate a real-time compliant digital twin from test data for its washing machines. This AI-powered solution helped Mabe meet its sustainability, quality, cost, and efficiency goals.

“romAI helped us leverage the value of our historical data. Now we are more enabled than ever to continue optimizing our sustainable products and features.”

— Martin Ortega, Ph.D., design manager, Mabe

Airworthiness and Multidisciplinary Optimization

Leonardo leveraged Altair® romAI™ to build and train efficient reduced order models (ROMs) with Altair® HyperStudy® simulation data. This solution addressed two important aircraft design challenges: airworthiness and multidisciplinary optimization for a power unit.

“The romAI technology seamlessly integrated into our current workflow and gave us highly accurate results while reducing the HPC time needed to perform our simulations.”

— Federico D’amico, digital engineer specialist, Leonardo

Thermal Management for Electric Vehicles

Discover how Chery Automobile Company adopted Altair® romAI™ to address thermal management and reliability challenges for its electric vehicle (EV) designs.

“romAI allowed us to work with incredible precision and eliminate technical bottlenecks. For those of us in engineering who may not excel in AI or programming, romAI’s visual interface makes training AI models simple and accessible.”

— Wang Shuang, supervisor analyst, Chery Automobile Company

Operational Digital Twin

Advanced Engineering Solutions (AES) collaborated with Altair to monitor and improve a sheet metal forming process for a leading parts manufacturer. To address this challenge, the team leveraged romAI to create efficient ROMs and deploy them into a digital twin of the entire manufacturing process.

“The efficiency of the romAI models made it possible for us to get immediate feedback about the production quality of our manufacturing process. The digital twin advantage gave us a clear and near real-time view of the entire process. This visibility enabled us to identify manufacturing issues and therefore make the needed decisions to address them.”

— Antonio Del Prete, CTO, Advanced Engineering Solutions

Deep Learning for a Real-Time Hardware Application

This study explains how romAI was used to turn high-fidelity 3D simulations into an efficient and accurate deep learning model deployed for a real-time hardware application.

“romAI merges a user-friendly interface with an explicit definition of the training parameters. This combination enables users to produce accurate models that are easily deployable.”

— Giuseppe Gullo, senior FEA analyst, CNH Industrial

Featured Applications

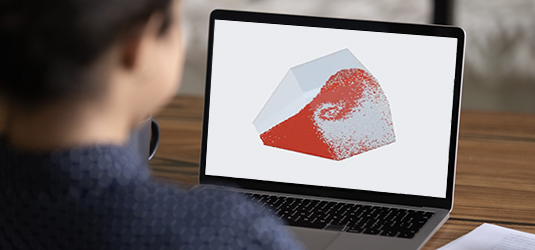

Speeding Up Simulations via Model Order Reduction

AI power is key to generating accurate ROMs.

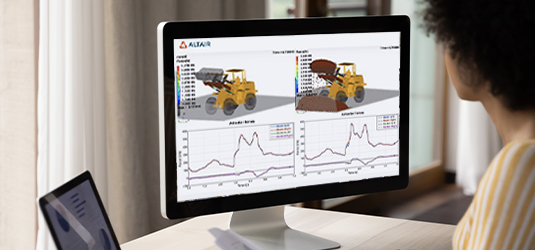

Creating High-Fidelity Optimization Models

Combine AI and simulation for efficient bulk solids handling.

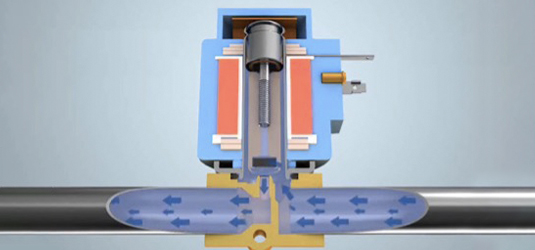

Holistic Multidisciplinary Simulation

Accelerate a solenoid valve analysis using AI and multiphysics.

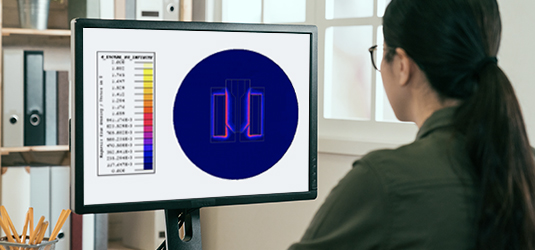

Different Orders of Model Fidelity

Generate an efficient, accurate ROM of a linear actuator.

Additional Resources

Getting the Signal with Digital Twin - Leonardo Deploys Digital Twin to Capture In-Flight Behavior of Helicopter Radar

Leonardo needed to correct a helicopter radar transmission loss caused by in-flight vibration to the helicopter's radome. Leonardo deployed Altair's digital twin solution to solve the problem. Using a multiphysics approach, the team created a digital twin of the radar antenna's structural and electromagnetic systems. They then correlated deformation to the antenna's design, tracked changes based on vibration, and calculated the antenna's electromagnetic signature. With these findings, Leonardo could optimize its next antenna build version without using expensive prototypes. Altair's solution also closed loops and slashed turnaround times between Leonardo's structural and electronics engineering departments by enabling teams to evaluate the radome and antenna system models in a unified ecosystem. The resulting streamlined workflows produced valuable insights into the antenna radiation patterns, physics drivers, and best trade-offs early in the development cycle, saving Leonardo time and technical resources.

romAI and Altair® nanoFluidX®: Leveraging AI on Drivetrain CFD Simulations

Learn how romAI can predict the thermal behavior of gearboxes during operations by smartly reusing data from nanoFluidXR oil flow simulations. To solve the thermal problem, a dynamic non-linear ROM is generated to estimate the gear-oil heat transfer coeff

Altair romAI: AI-powered Solution to Speed-up System Design and Optimization

Nowadays, machine learning techniques are used in many applications. In the field of reduced-order modeling, they are conveniently used especially when dealing with complex non-linear systems when a standard equation-based approach can’t achieve the needed performance in terms of efficiency and accuracy. To tackle this need, Altair has developed a novel approach: Altair® romAI™.

This application combines AI and system modeling techniques to generate reusable static or dynamic models extremely time-efficient, hence able to speed-up system design and optimization.

Besides introducing the romAI approach, in this session we present 2 applications of romAI applied on Altair® EDEM™ simulations to better understand and appreciate the benefit of this novel approach in the DEM discipline.

Presented as part of the virtual ATCx DEM in November 2022.

Speaker: Livio Mariano, Director Math Systems, Altair

Duration: 15 minutes