Altair® SimLab® Applications

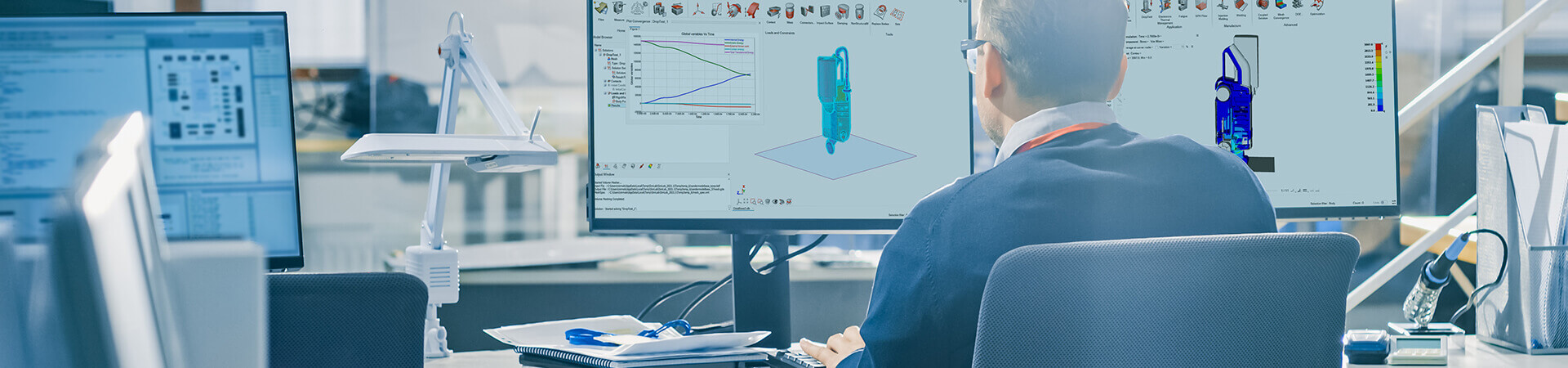

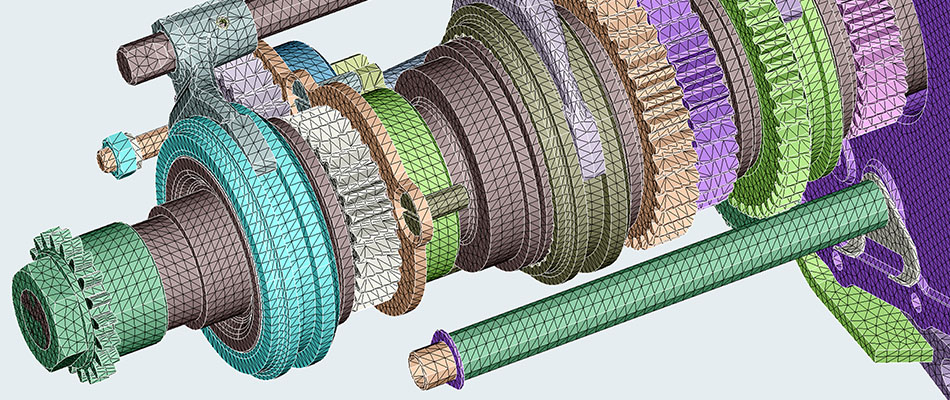

Altair SimLab is a process-oriented multidisciplinary simulation environment used to analyze the performance of complex assemblies. Multiple physics, including structural, thermal, electromagnetics, and fluid dynamics, can be easily set up using highly automated workflows, significantly reducing the time spent creating finite element models and interpreting results.

Learn More About SimLab

Enhanced Chip and 3D IC Reliability

Altair’s Electronic System Design (ESD) solution simplifies and accelerates the design of integrated circuits (ICs) and 3D packages using a unified process built around a 3D digital twin. With SimLab, engineers can explore different chiplet layouts, analyze power and cooling performance, and spot thermal hotspots early in the design phase. SimLab also boosts reliability by addressing warpage issues. With integrated, proven workflows, chipmakers can design more reliable and cost-effective systems with greater confidence.

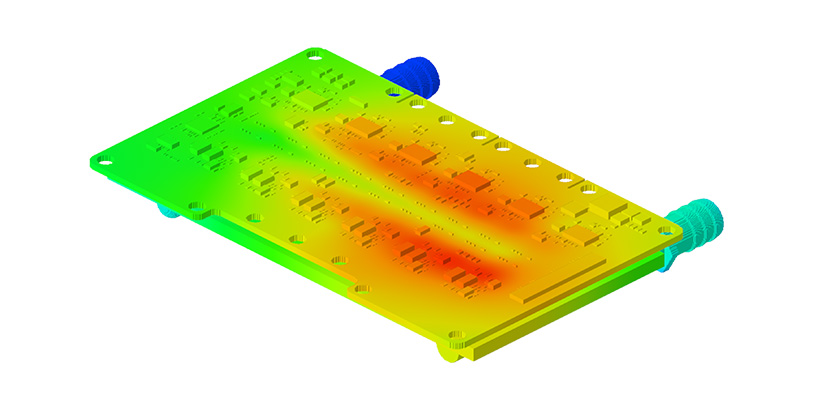

Electronics Cooling and Thermal Management

SimLab makes it easy to evaluate and optimize thermal behavior in electronic systems without requiring advanced CFD expertise. Model heat dissipation, airflow, and thermal coupling to ensure safe, efficient operation.

Use cases:

- Printed circuit board (PCB)-level and system-level thermal simulation

- Joule heating, convection, and conduction modeling

- Liquid and air-cooling design (fans, heat sinks, TECs)

- 2R-modeling for simplified system-level analysis

- Dynamic load conditions and control systems

Structural Reliability of Electronics

Protect product performance and longevity with advanced structural analysis. SimLab provides automated workflows for evaluating mechanical stress, deformation, and failure in electronics.

Use cases:

- Drop test simulation (consumer electronics, PCBs)

- Thermal warpage and deformation analysis

- Solder fatigue prediction (thermal and vibration-based)

- Delamination and shock analysis of components

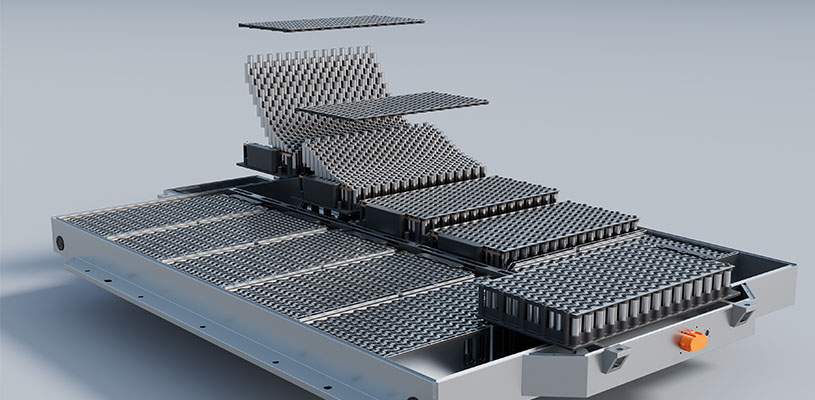

Battery Simulation and Safety

Design safe and efficient battery systems with SimLab’s multiphysics capabilities. Simulate electrical, thermal, and structural behavior to avoid overheating and predict mechanical failure.

Use cases:

- Joule heating in battery cells and busbars

- Transient electrical-thermal-flow simulation

- Structural warpage and fatigue under load

- EV inverter cooling and safety validation

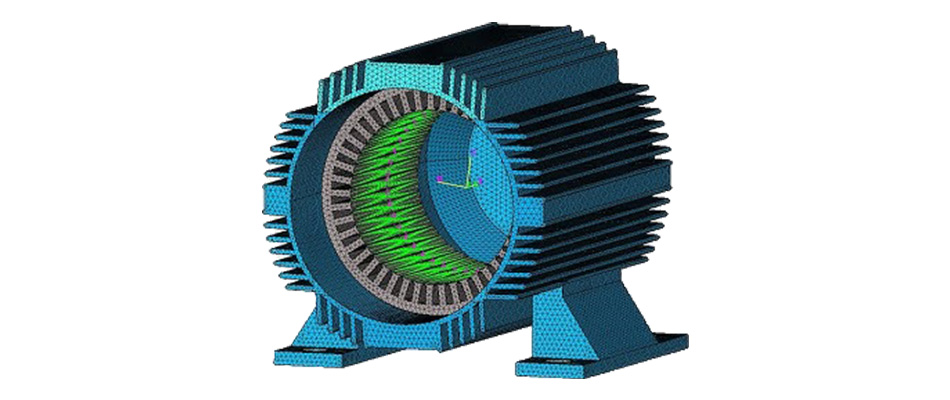

Low Frequency Electromagnetics

Accelerate the development of electric motors, sensors, and actuators with built-in electromagnetic analysis powered by Altair® Flux®. SimLab seamlessly couples electromagnetic (EM), thermal, and structural physics.

Use cases:

- Electric motor design (PMSM, SRM, WRSM, axial flux)

- Magnetic force and loss evaluation

- Coupled noise, vibration, and harshness (NVH) and thermal analysis

- Power electronics and high-voltage component design

Explore more multidisciplinary simulation solutions.

Contact Us

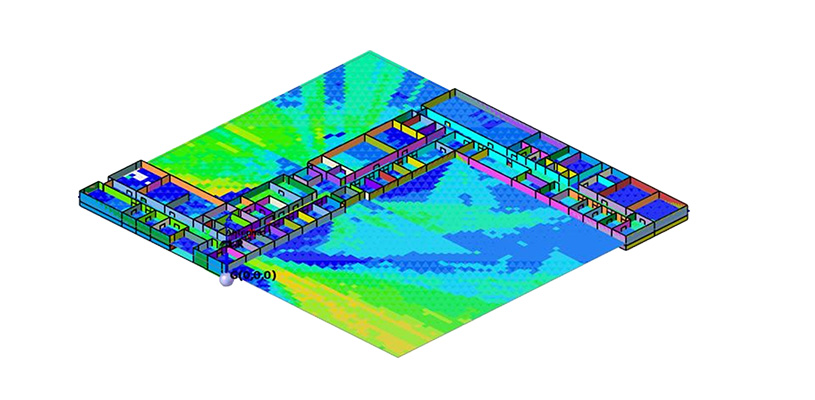

High Frequency Electromagnetics

Analyze signal propagation in communication networks using a range of wireless standards, including 5G and LTE. Design and assess the high-frequency electromagnetic performance of components and systems with integrated simulation capabilities powered by Altair® Feko®.

Use cases:

- Radio coverage analysis (indoor)

- Network planning

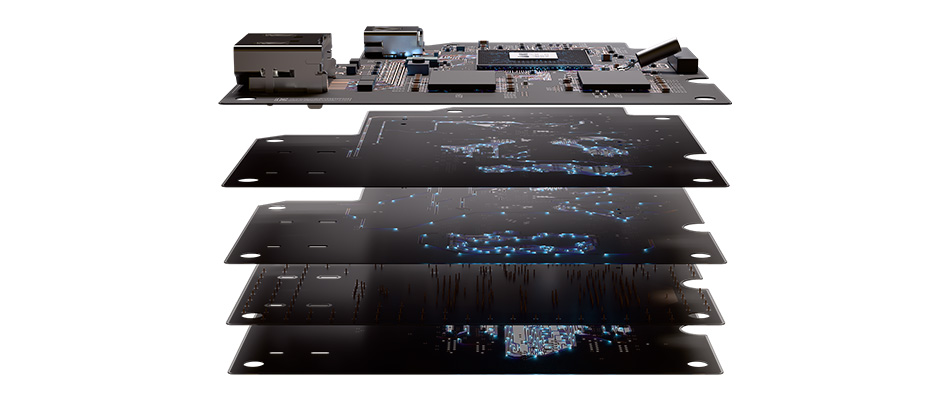

PCB and Electronic Packaging Analysis

SimLab provides robust workflows for PCB-level analysis, including mechanical, thermal, and fatigue evaluations. Work directly from ECAD and optimize packaging designs.

Use cases:

- Detailed, homogenized, and hybrid PCB modeling

- ECAD-to-simulation workflows

- Trace mapping and material property automation

- Thermo-mechanical warpage and shock analysis

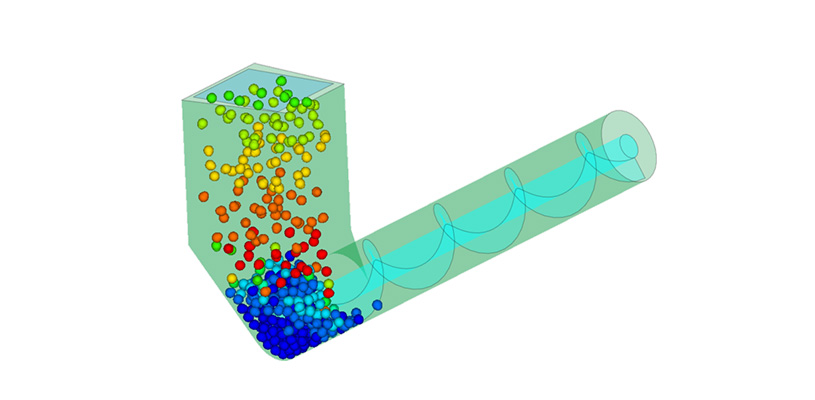

Particle-Based Simulation and Coupling

SimLab enables advanced particle-based simulations through coupling with Altair® EDEM™, allowing accurate modeling of granular material interaction with structures and fluids.

Use cases:

- Structural wear and erosion prediction

- Granular flow behavior in chutes or mixers

- CFD–particle coupling for fluid-solid interaction

- Soil-structure interaction in heavy equipment

- Powder compaction and flow behavior in manufacturing

Design Automation and Optimization

Streamline simulation setup, increase repeatability, and explore the design space with built-in automation and design of experiment (DOE) tools. SimLab supports both scripting and no-code customization.

Use cases:

- Parametric studies and optimization (DOE)

- CAD and solver parameter variations

- Python scripting and GUI customization

- Workflow templates and simulation standardization

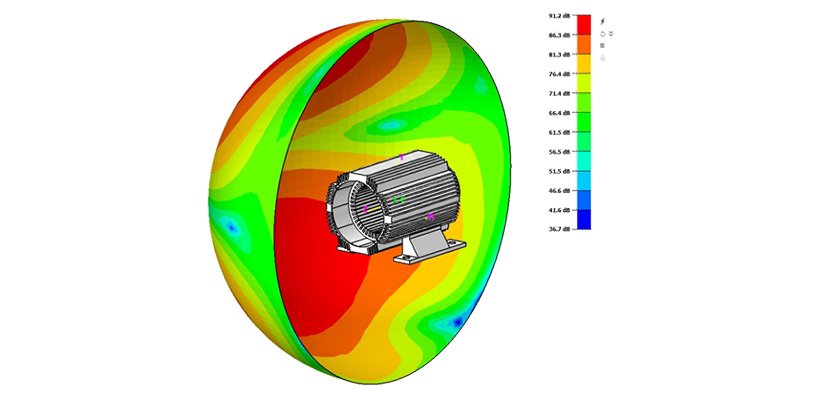

NVH and Acoustic Validation

Reduce unwanted noise and vibration in mechanical and electrical systems. SimLab supports fully coupled NVH simulations, enabling designers to analyze acoustic performance early in the design process.

Use cases:

- Vibro-acoustic simulation of electric motors

- Waterfall and order tracking analysis

- ISO-compliant microphone and panel placement

- EM-to-structural-to-acoustic force mapping

Featured Resources

6 Electronics Failures You Can Prevent with an Integrated Simulation Approach

Electronic devices today are remarkably reliable, but that reliability is no accident. It stems from skilled design and engineering and a rigorous design process powered by advanced simulation and multiphysics analysis. When companies skip or underinvest in simulation at the design stage, they take an enormous risk, often resulting in failures late in the design cycle, during testing, or in the field—where they're far more costly and damaging.

As devices become more compact, powerful, and precise, traditional single-domain analysis falls short. Most real-world failures arise from interactions between electrical, thermal, and mechanical domains.

This guide explores six real-world failure modes that can be prevented with an integrated, multiphysics simulation strategy. From thermal runaway to mechanical stress fractures to gradual deterioration due to multiphysics interactions, each example highlights how Altair® SimLab®, together with other Altair tools such as Altair® PSIM™ (power simulation) can help identify risks early, reduce costly redesigns, and ensure robust performance from the first prototype.

Expert Chat: Multiphysics Workflows in Altair SimLab

Presentation by Kamila Klug, Director, Business Development Material Solutions and Farhad Behafarid, Director, Electronics Thermal with Altair as part of Altair's Simulate at the Speed of Design 2025 conference.

Altair SimLab is a comprehensive multiphysics platform designed to streamline the end-to-end workflow from CAD to results, with a particular focus on electrification and electronics design. By integrating multiple solvers and advanced pre/post-processing in a user-friendly environment, SimLab enables fast, accurate analysis for thermal and mechanical reliability in electronics. This session explores its application in accelerating electronics design through seamless CAD and multiphysics integration.

Next-Level Thermal Management

Myway aimed to validate Altair’s thermal simulation solution against its own physical test data for a Rohm silicon carbide (SiC) inverter. Two key challenges had to be addressed: heat Loss calculation and thermal path and airflow management. Myway found that Altair's PSIM-SimLab workflow delivered accurate predictions that aligned with real-life data, providing insights for streamlining development time.

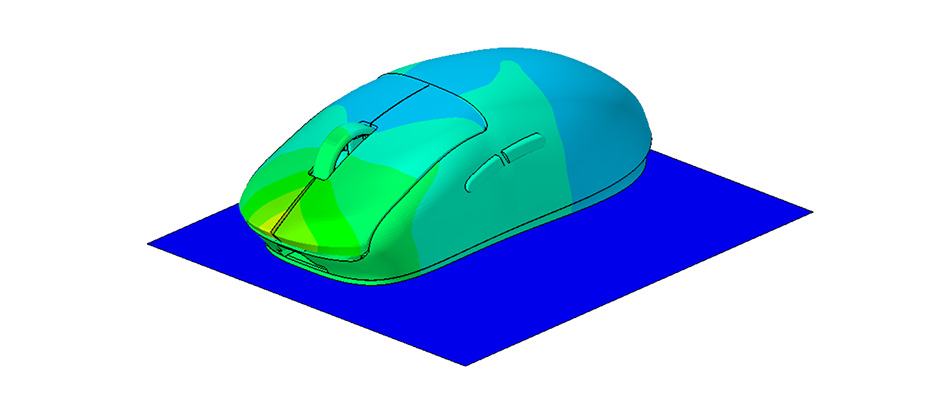

Accelerating Innovative Product Development for Consumer Electronics

Presented by Alice Lin, Manager Mechanics at GN Audio (China) Ltd., as part of Altair's Simulate at the Speed of Design 2025 conference.

In the realm of consumer electronics, rapidly innovating novel products has always been a challenge. Conventional simulation software's preprocessing phase has proven time-consuming, especially when dealing with complex models like full device drops.

Furthermore, the limitations of single-purpose solvers, e.g. separate purchases are required for structural and fluid analysis, have constrained the potential of simulation engineers.

Since 2018, Jabra started using Altair software in product design. By adopting SimLab, the preprocessing efficiency has been improved obviously, allow simulation experts saving time to delve new problem domains. SimLab also functions as a versatile preprocessing tool for fluid and thermal simulations, thus also can be used to solve thermal management challenges. Additionally, the software supports Design of Experiments (DOE) and topology optimization, enabling refined design enhancements. Empowered by Altair software, even a small-scale simulation team can seamlessly address an array of concerns encompassing structural, thermal, and even optical simulations.