veoCAST by Teraport

Simplified CAD Part Analysis for Casting and Molding

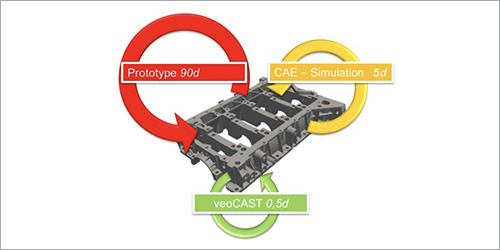

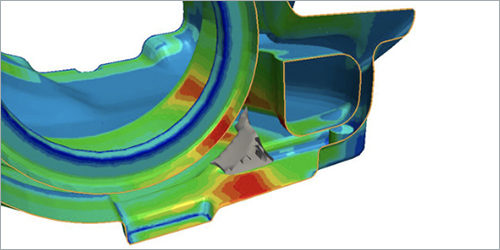

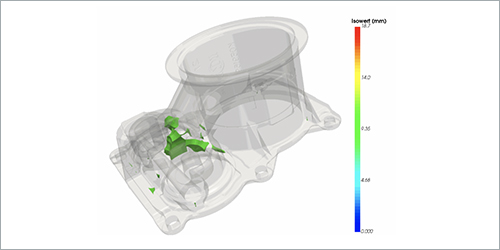

veoCAST is a stand-alone software for the analysis of CAD parts regarding their conformity with casting process requirements (design for manufacturing). With veoCAST, all a part’s relevant criteria can be analyzed quickly with no need for FEM casting

simulation. The only prerequisite is the CAD part – no further information on the tool or manufacturing process is necessary. As such, potential problem areas of the cast part can be detected and eliminated at an early stage. veoCAST can be used well before the full-scale finite element process simulation is scheduled. Thanks to its easy handling and intuitive visualization, veoCAST can be used in the design phase and also to enhance procurement and sales processes.