Altair® Twin Activate® Applications

As demand for smarter, more connected, and more sustainable products increases, companies need digital twin tools that can simulate efficiently at the whole system level.

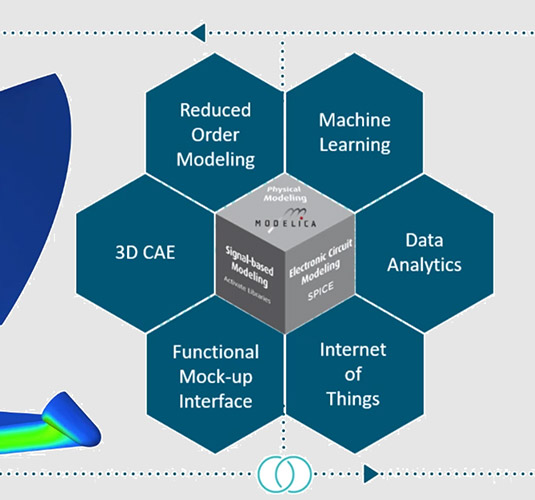

Twin Activate’s multidisciplinary simulation capabilities help companies develop smart, complex mechatronic systems holistically while enabling streamlined product development workflows and collaboration between diverse engineering domains. Twin Activate breaks down silos between mechanical subsystems, electrical subsystems, control subsystems, electronic subsystems, software, hardware-in-the-loop, data analytics, and more.

Learn More About Twin ActivateDigital Twins

Leverage Twin Activate as the core of Altair's open, flexible digital twin platform to easily combine high-fidelity models with reduced-order models (ROMs) built using 3D+1D+0D techniques (i.e., using CAD geometry + block diagrams + equations).

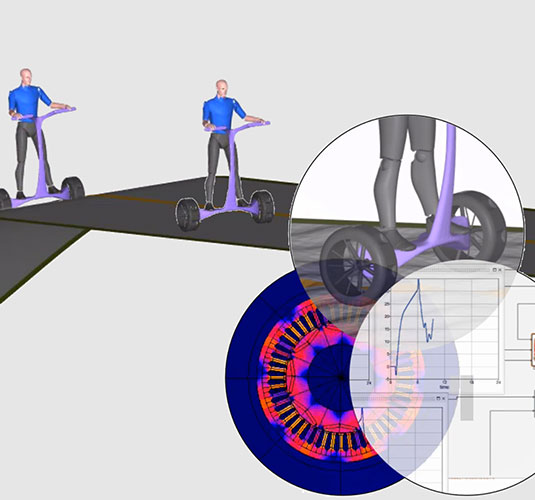

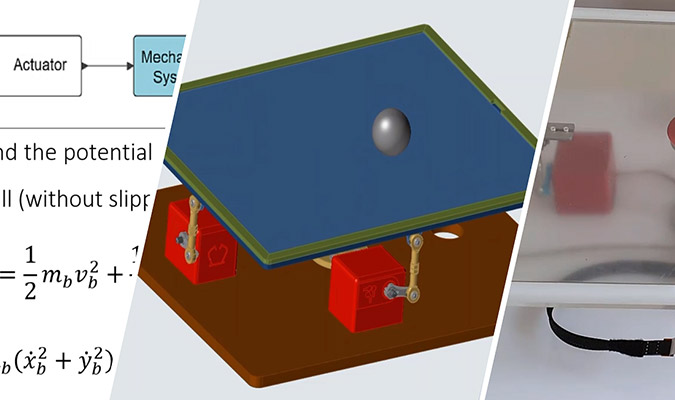

Integrated Multi-disciplinary Systems

Integrate models for mechanical, electrical, and controller subsystems (including sensors and actuators) to simulate your mechatronic product holistically as a system-of-systems. Exchange models and/or co-simulate with other CAE tools either from Altair (such as Altair® MotionSolve® and Altair® Flux®) or from third parties through the Functional Mockup Interface (FMI) open standard.

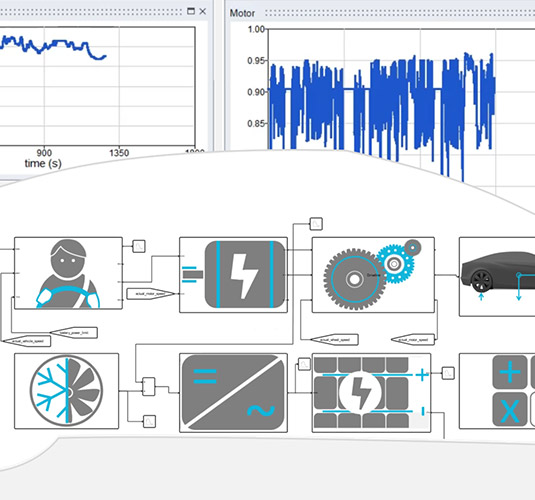

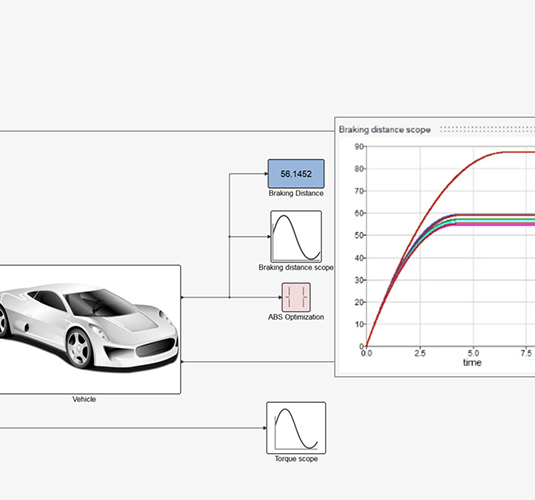

Electric Vehicle (EV) Systems

Simulate electric powertrains for various types of vehicles combining mechanical plant models with motors, batteries, and controllers together with realistic drive cycles. Then, optimize the overall performance of your electric vehicles (optionally, in combination with Altair® HyperStudy®).

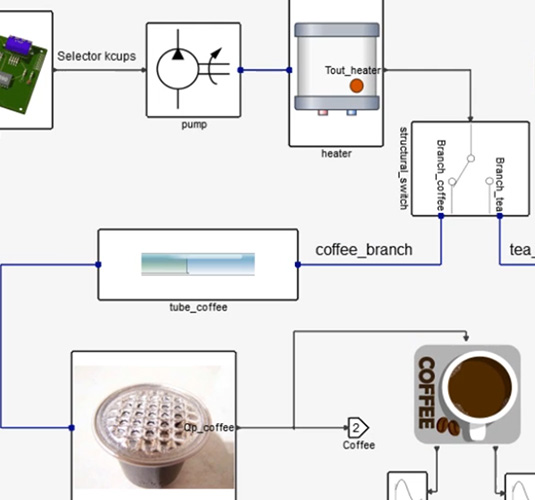

1D Thermal-Fluid Dynamic Systems

Model thermal-fluid system dynamics using 1D modeling &and simulation (rather than using only 3D CFD) to yield nearly-as-accurate results significantly faster – to enable more design exploration and optimized performance in less time.

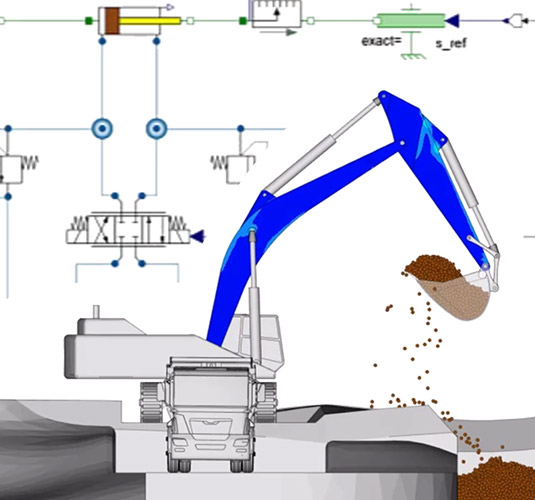

Hydraulic Systems

Create detailed hydraulic circuits and actuation systems as part of multi-disciplinary system simulations – particularly for heavy machinery and agricultural equipment, in combination with multi-body systems and granular material systems.

Model-based Systems Engineering (MBSE)

Connect product-level system simulations to your product's functional requirements so that your system model serves as the Authoritative Source of Truth (AST) for virtual product development activity.

Featured Resources

Sensor Accuracy Drives Performance - Model-Based Development Improves E-Motor Reliability and Efficiency

High accuracy sensors and encoders are integral components of an e-motor drive, greatly impacting the quality and efficiency on the system. A purpose-driven simulation approach is needed to account for all the physical interdependencies within these complex multi-domain systems. Lenord + Bauer worked with Altair to develop a system simulation process for their high-accuracy encoders to understand their impact on the quality and efficiency of the system.

Open Integration of Digital Twins and Model Based Systems Engineering (MBSE)

Dr. Cynthia Dean is the Director of Model Based Systems Engineering (MBSE) Training and Solution Development at Belcan. She will present a future facing vision for integrating model-based systems engineering, architecture, and simulation with digital twin technology in modern systems engineering. The presentation will highlight the major Industry challenges in adopting these technologies and how Belcan and Altair have joined forces to uniquely address the challenges via an open Integration platform.

Human Plus Machine: How Sarcos is Revolutionizing the Future of Work with Industrial Robotics

With the prospect of increasing labor shortages among a wide variety of industries, combined with the significant costs of occupational injuries and the ever-increasing pressure to increase productivity, leading robotics company, Sarcos is in a unique position to deploy industrial robotics designed to increase productivity while eliminating injuries, by augmenting rather than replacing human workers.

Chris Beaufait, COO of Sarcos, discusses the current robotics landscape, why automation is not the right solution to the problems industries are facing, how Sarcos and its product lineup - including the full body, fully powered Guardian XO exoskeleton - will play a critical role in defining the workforce of tomorrow, and his vision for the robotics industry over the next five to 10 years.

Achieving Aerospace Design Confidence with Model-based Systems Engineering

Reducing aircraft design and development time is critical for all aircraft manufacturers, from urban air mobility and electric aircraft startups to military to commercial OEMs. In order to fully understand and optimize the complex systems of systems required in modern aircraft, aerospace engineers leverage a simulation method called Model-based Systems Engineering (MBSE). MBSE allows the evaluation of various types of vehicle systems to determine which best meet the mission requirements.