CAD Data Quality and its Importance in Downstream Data Interoperability

Throughout the product manufacturing lifecycle, specialized software exists for specific fields, creating a need to ensure one has “the right software in the right place.” It is without a doubt that many software solution providers have stood up to challenge this status quo, which has not been easy.

As a result, numerous software developers have developed the culture of complementing others’ weaknesses and functionalities. What becomes a seed of discussion is how these complementary solutions communicate with each other. There has been movement of standardized neutral formats to universally bridge the gap between the different languages. ISO standards such as STEP and JT have risen to a level where they are widely used by suppliers as an exchange format. While these solutions offer a good place to start, it is also important to consider how the quality of the data or Product Data Quality (PDQ) is preserved and maintained throughout the process.

So, what is the definition of “good quality” data? What happens when we do not have good quality data?

With the constant and rapid changes in market trends today, it goes without saying that shorter lead time for manufacturing is a necessity. What once took several years to complete now has to be done in two to three years, and what originally took days, will have to be done in hours. Time is ticking but how do we overcome this obstacle?

The key here is the ability to pass digital data one player to another in a seamless manner. Very simple, but difficult to do. This requires knowledge of each unique system’s characteristics as well as having “good quality” data.

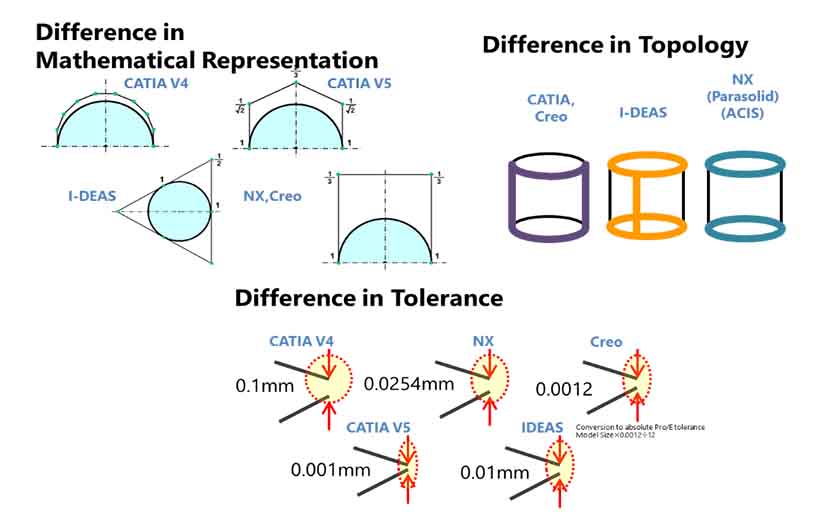

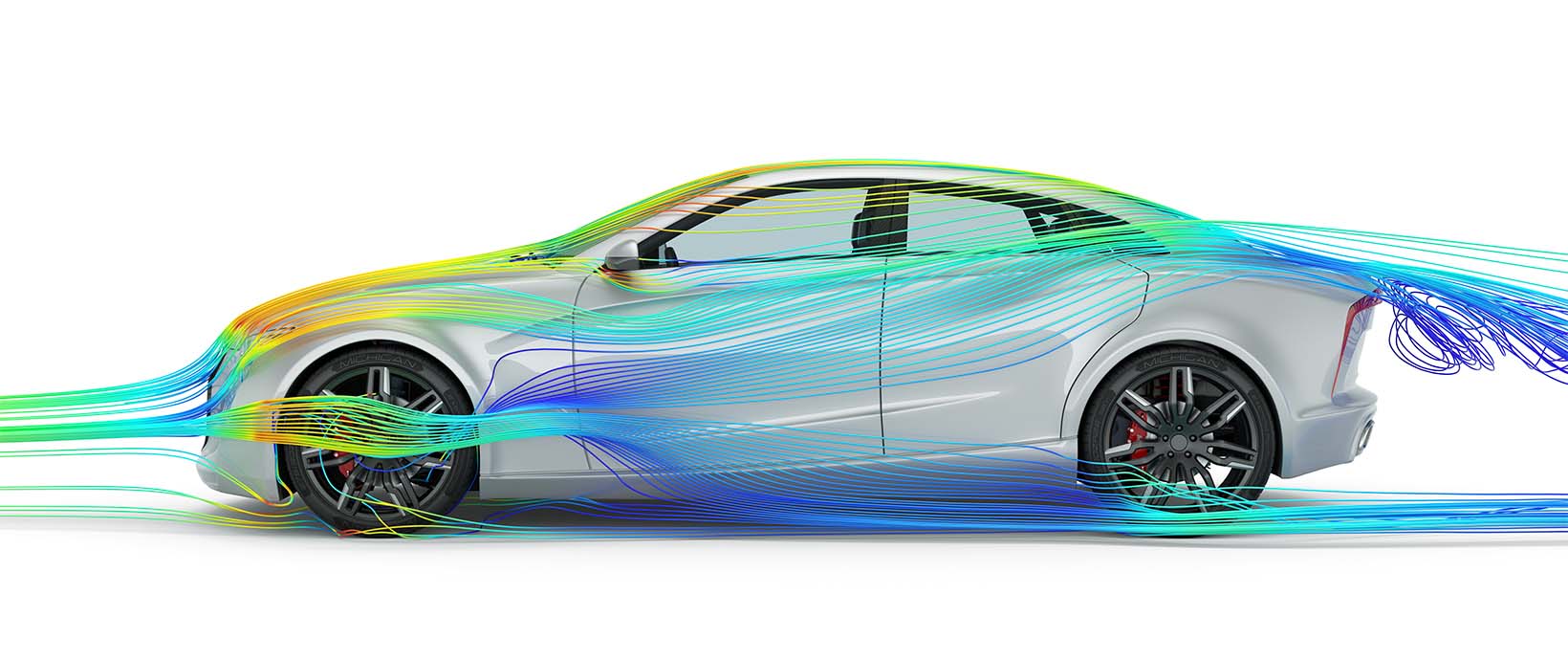

Each unique system has its own style, and whether the data is going from one CAD system to another, or even going up and down different versions in the same system, there are obstacles that bind the communication, like between processes of design and simulation, for example.

The image reflects how each system has its own representations and proves why bridging systems is a difficult task

“Quality” refers to whether the modeled data meets a certain set of criteria, but in terms of 3D geometry data translation, it is important to satisfy the topological and tolerance requirements of what you are translating to. This becomes the first step of having “good quality” data.

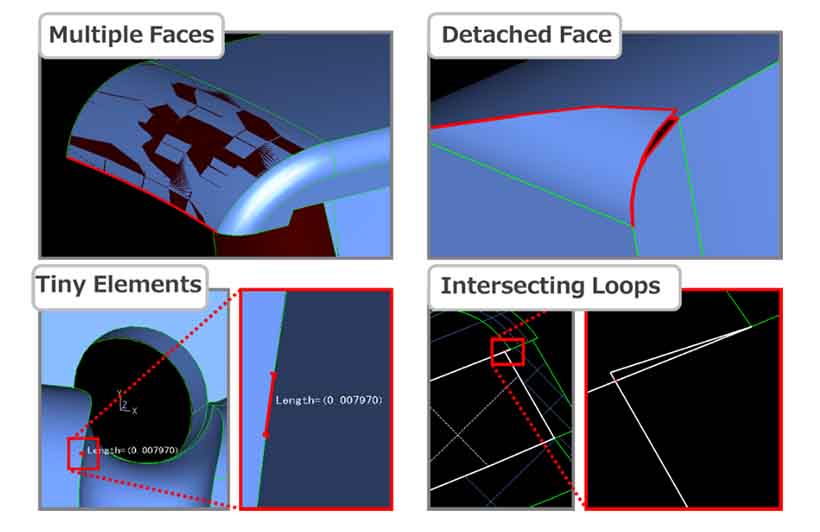

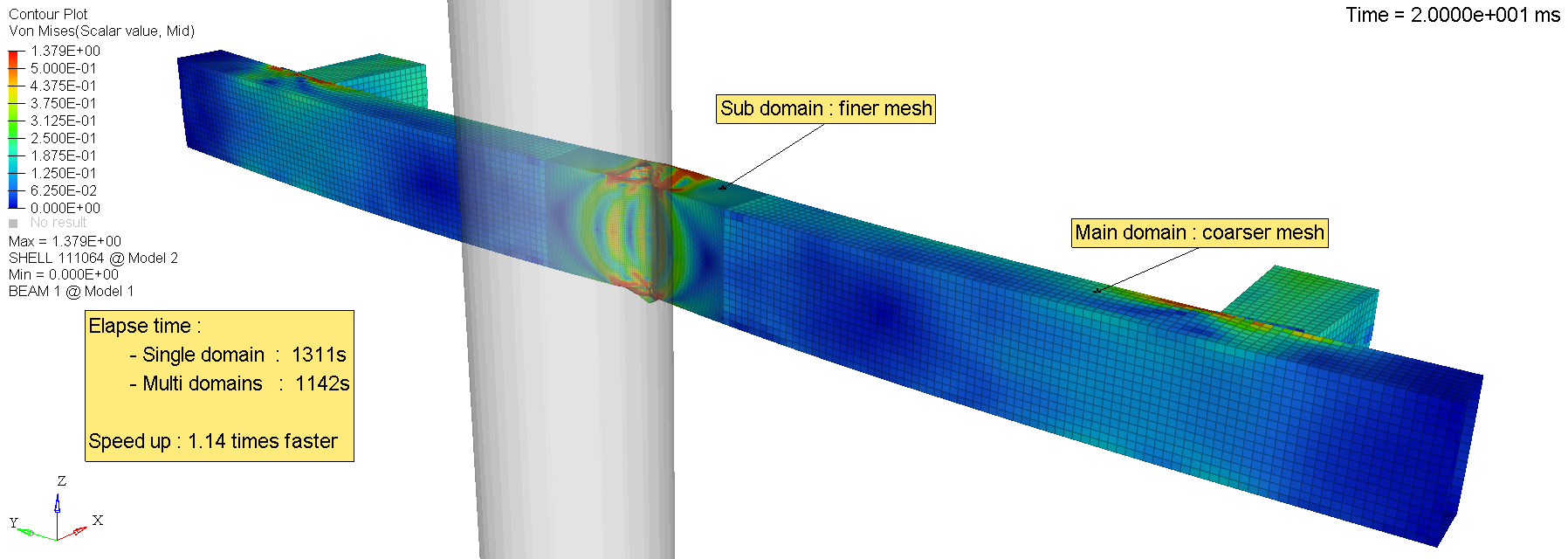

Even if all the topological and tolerance conditions are taken into consideration, there are cases where geometry errors, such as that below, could result in failure of mesh creation.

Examples of geometrical errors which causes problems in downstream data processing, such as mesh creation

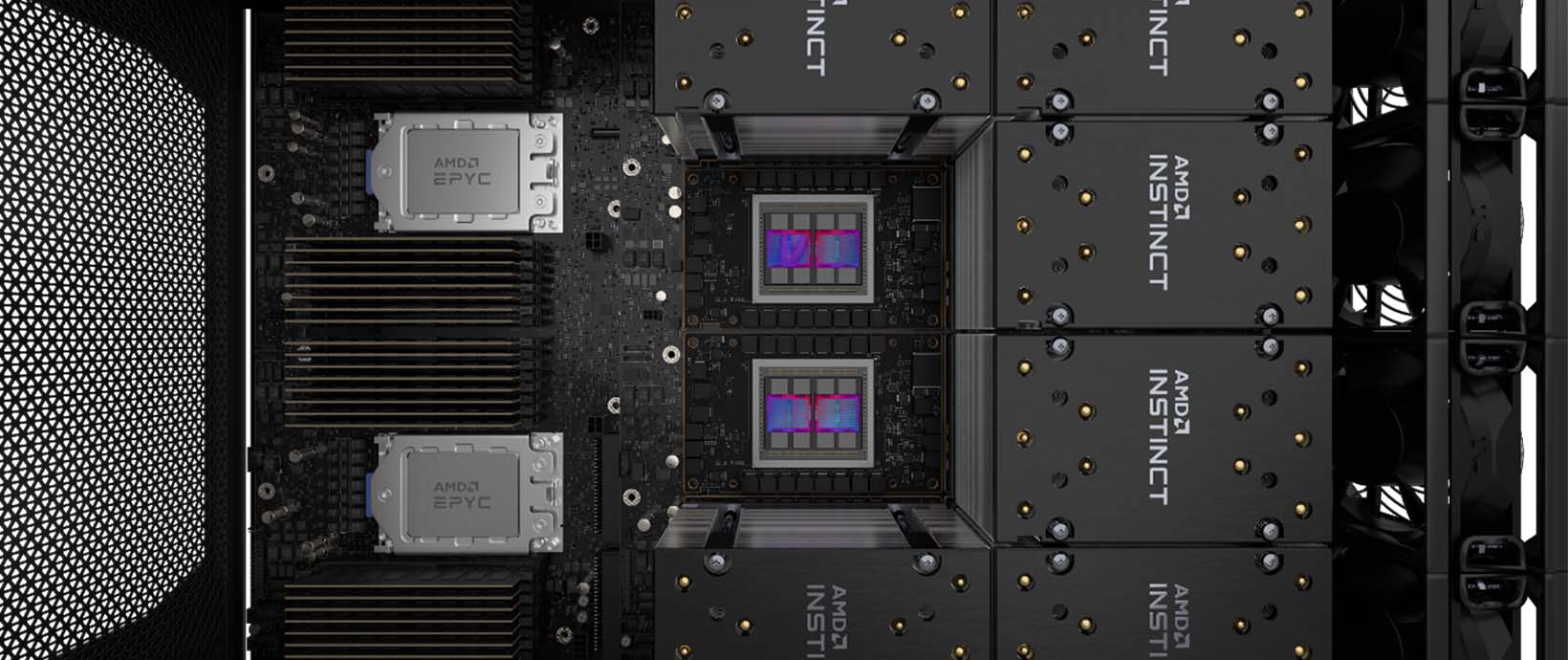

CADdoctor offers a solution for these problems. Based on over 30 years of experience handling sophisticated geometry, this desktop application is a user friendly tool for high-quality translation and optimization of 3D data. Configurations for the ideal quality criteria for each system are done automatically, and detailed settings for individual jobs can be performed as well. This simple yet powerful solution will “heal” the data in a way so that it is in the optimal state for simulation, eventually minimizing the lead time for the entire product manufacturing lifecycle.

(Top left) CADdoctor

(Bottom right) Geometrical errors which are often found as problems in meshing

To learn more about CADdoctor, as well as ways to build a workflow with Altair solutions, register for the upcoming workflow webinar (http://web2.altairhyperworks.com/hypermesh-caddoctor-workflow-webinar) and make the next step toward a successful project.