Improving Quality and Lifetime of Forged Products with Process Simulation

This guest contribution on Innovation Intelligence is written by Adhish Majumdar, Research Engineer at GeonX, and Laurent D’Alvise, CEO & Founder at Geonx. Virfac® by GeonX is a tool used to simulate welding, additive manufacturing, machining, heat treatment and damage resistance and is available through the Altair Partner Alliance.

There are several techniques used to perform surface hardening on large steel parts, the most popular of which is induction hardening. Induction hardening is a very quick process that allows precise control of the hardening depth and leaves the surface clean and smooth. Simulating this process ahead of time helps overcome several challenges and saves time and money during the production process. A couple of these challenges include unexpected hardening depths due to an improper temperature profile and distortions and residual stress “hot spots” which can both lead to an increased number of trials before production. Virfac®- Virtual Factory developed by GeonX, makes it possible to easily setup and simulate the entire manufacturing chain in order to optimize the parameters involved in the induction hardening process. This simulation results in higher quality and longer-lasting products.

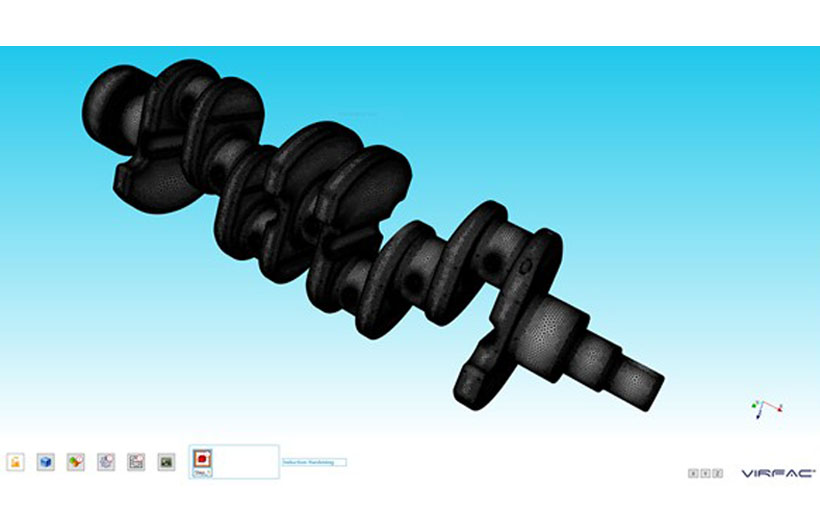

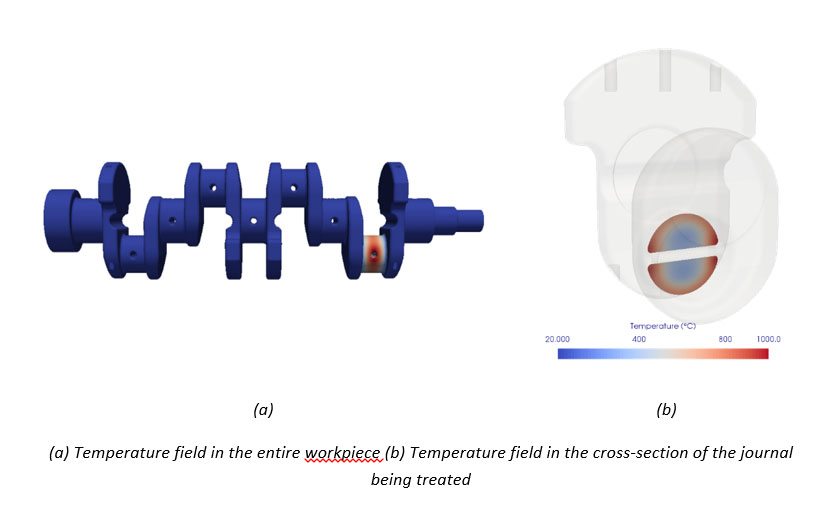

This article presents results of simulations of the surface hardening heat treatment on a forged crankshaft. Surface hardening is done to increase the fatigue resistance and service life of crankshafts, which continuously experience cycling loads. The treatment consists of heating the surface of a journal by induction to above the austenitization temperature, followed by quenching in an agitated water bath, resulting in a layer of martensite on the surface.

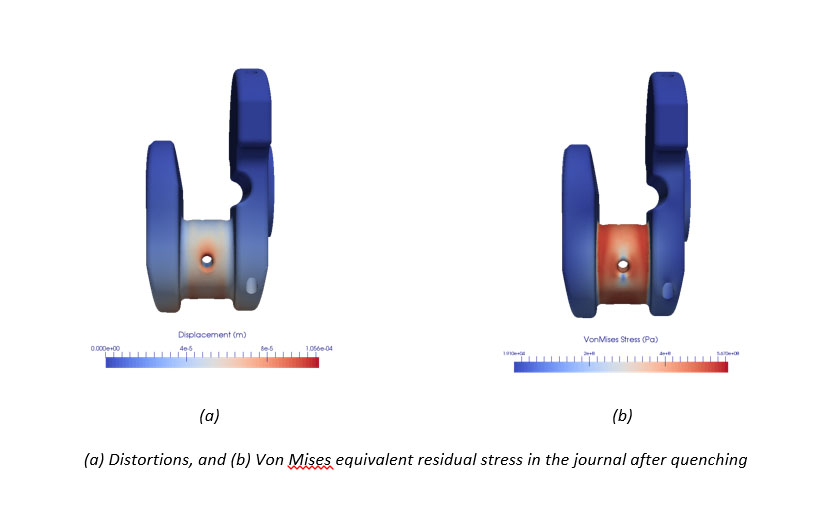

The simulations implement a strong coupling between the thermal, metallurgical, and mechanical phenomena and predict the distortions and residual stresses in the quenched workpiece. Taking the metallurgical phase transformations into account is crucial in order to represent the gradient of material properties produced by the surface heat treatment.

Chaining between Virfac® and JMAG

The simulations are set up using Virfac® and the temperature rise due to induction is simulated using JMAG, a specialized software for magnetic induction developed by JSOL Corporation. These temperatures are then used in the coupled simulations. The size and complexity of the crankshaft geometry results in a mesh containing 1 million nodes and 6 million elements. The simulations were carried out on a high performance computing (HPC) facility using the finite element solver Morfeo.

Setting up the heat treatment simulation of a crankshaft using Virfac® - Virtual Factory developed by GeonX

Setting up the heat treatment simulation of a crankshaft using Virfac® - Virtual Factory developed by GeonXResults and Validation

The currents induced in the journal heat the material in a thin layer near the surface. This thin layer, heated beyond the austenitization temperature, converts from the initial ferrite-pearlite-bainite phase to austenite.

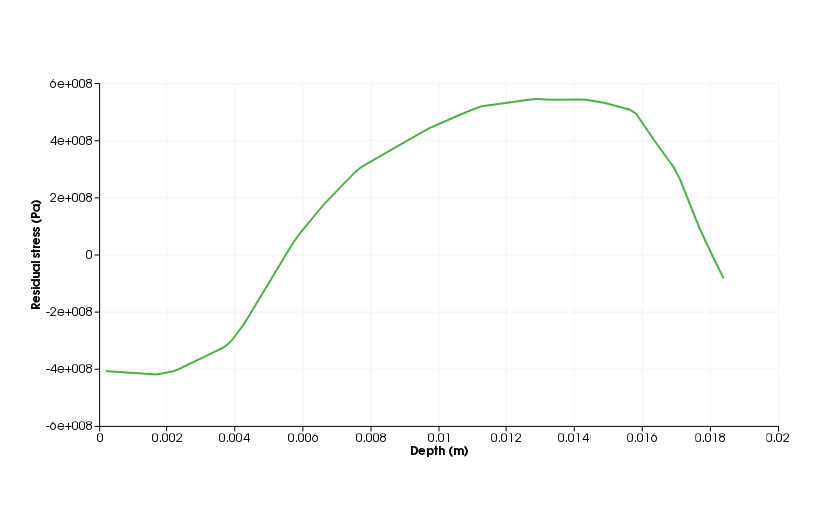

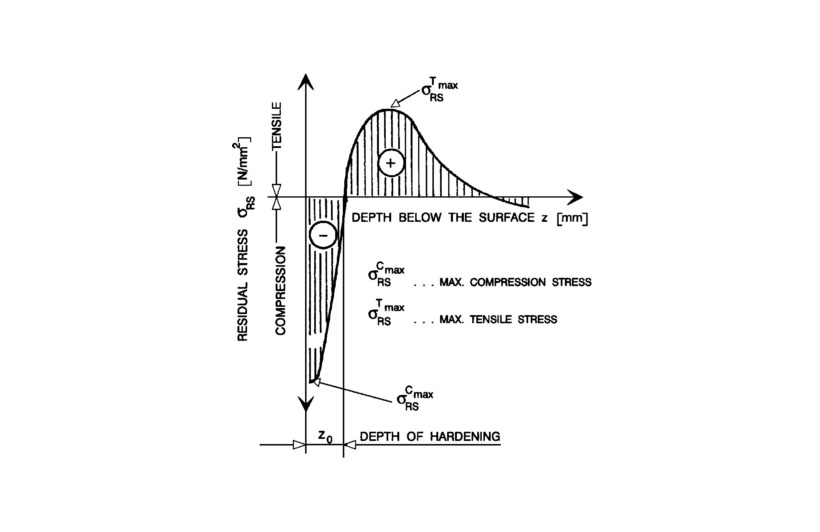

After the quenching process, the thin layer of austenite transforms to martensite. The phase transformation is accompanied by changes in volume, because the densities as well as coefficients of thermal expansion of austenite, ferrite-pearlite-bainite, and martensite are all different. In addition to this change of volume, there is a transformation induced plasticity which introduces some plastic strains into the material. All these phenomena result in distortions and residual stresses in the journal, and are predicted by the simulation

After the quenching process, the thin layer of austenite transforms to martensite. The phase transformation is accompanied by changes in volume, because the densities as well as coefficients of thermal expansion of austenite, ferrite-pearlite-bainite, and martensite are all different. In addition to this change of volume, there is a transformation induced plasticity which introduces some plastic strains into the material. All these phenomena result in distortions and residual stresses in the journal, and are predicted by the simulation

Summary

This demonstrates the capacity of Virfac® to import results from a simulation of electromagnetic induction carried out using JMAG, and then simulate the following heat treatment process.

The temperature field resulting from currents induced magnetically in a crankshaft journal were calculated using JMAG. The calculated temperature fields were used in Virfac® in a thermal-metallurgical-mechanical simulation to obtain the phase fractions and distortions resulting from the heating, and a subsequent quenching step. The residual stress profile predicted by Virfac® was compared to the typical stress profile obtained after induction hardening and a very good correspondence was observed. Through this simulation, the process parameters were optimized to obtain the required hardening depth. This, coupled with the least possible amount of distortions and residual stress hot spots leads to a longer service life of the manufactured part.

Acknowledgements

The authors would like to acknowledge Takahiko Miyachi and Toshihiro Hayashi of JSOL Corporation for providing the license of JMAG used for the electromagnetic-thermal simulations.

References

[1] P. Bristiel, “Modeling thermal magnetic, metallurgical and mechanical surface hardening after induction heating applied to crankshafts” National School of Arts and Crafts, Center of Bordeaux, 2001.

[2] Grum, J. (2001). A review of the influence of grinding conditions on resulting residual stresses after induction surface hardening and grinding. Journal of Materials Processing Technology, 114, 212–226.