If Batman Was a Product Engineer, What Would Be in His Toolbelt?

Batman is known for his remarkable ability to seemingly always have the right tools for the right jobs at his fingertips. From grappling hooks to boomerangs, no matter the trouble he is in, his utility belt has tools always ready to go when trouble arises. Likewise, product engineers understand the importance of having access to the tools necessary for product development and analysis.

Presumably, when he’s not fighting crime, Batman is in the Bat Cave designing gadgets to help him against his next foe. So when he goes into product engineering mode, what tools would he need in his toolbelt?

Similar to the function of his utility belt, Altair SimLab™ is an essential tool that provides product engineers with all the modeling and solver technology they need along with a unified interface for multiphysics including fluids, thermal, electronic design, as well as structural analysis and optimization tools.

To ensure the proper technology is readily available, Altair designed this integrated multidisciplinary simulation environment to be easily navigated by all product engineers, even those without specific domain expertise.

To engineer his gadgets, Batman would need the following tools on hand...

Electronic system design

For electronics applications, SimLab automates structural stress, vibration, and drop test performance assessments with robust and repeatable workflows for fast, accurate, and consistent analysis, even for occasional users.

To protect the utility belt from falling into the wrong hands, Batman designed a taser to shock anyone attempting to access his gadgets. Electronic system design would be critical to make sure this device delivered a powerful but non-lethal shock without overheating the circuitry. There’s no doubt structural stress, vibration, and abusive load performance would also be key to ensure the intricate electronics were suitably protected during a fight.

Structural analysis and optimization

With application specific workflows for drop test, fatigue, and structural optimization, SimLab simplifies complex analysis problems. Navigating design space, responses, and constraints is simplified in the platform so multiple design alternatives can be compared and optimized in the same tool.

One of Batman’s most essential tools for both fighting and traveling is his Batarang. Not only used as a throwing weapon, Batman also utilizes this as a grappling hook when attached to rope. To support his bodyweight when climbing, structural analysis and topology optimization would be an important part of the design process for light weighting the tool while also guaranteeing enough strength to support his weight.

Thermal and flow analysis

Understanding the performance of a heat sink, convection heating system, or the cooling of an axle housing with fast meshing, material property assignment, and defined boundary conditions are important applications of SimLab for thermal analysis. Users can reduce the complexity of transient heat transfer, steady state, and transient flow, plus injection molding simulations all within the SimLab platform.

Since his utility belt houses enough gadgets for any type of crime or escape scenario, Batman has to make sure any possible defect or manufacturing error is avoided in the belt itself to ensure his safety. Using an injection molding manufacturing approach for production, he can guarantee manufacturability and eliminate defects in the belt, which uses lightweight, high-strength plastic materials.

Multiphysics modeling

With simulation-driven design, accelerating the simulation of structural, mechanical, thermal flow, and electromagnetic physics is possible using a single model. Observing these advanced simulation models provides insights into how parts and products will behave under real world conditions, and takes into consideration linear or nonlinear steady-state, linear transient analysis, or contact-based thermal analysis during the development process.

The infamous Ultrasonic Bat Beacon emits a high-frequency ultrasonic signal to attract swarms of bats to a targeted area or enemy. Using SimLab’s multidisciplinary simulation environment, Batman can use the tool to model thermal, mechanical, and electromagnetic properties to understand how these interacting physics would affect the Batcall’s performance under real-world conditions.

Process inefficiencies lead to product failure

Even though engineers and designers alike strive to follow a customer-centric approach to product development, a lack of both time and technology can hinder design goals from being met.

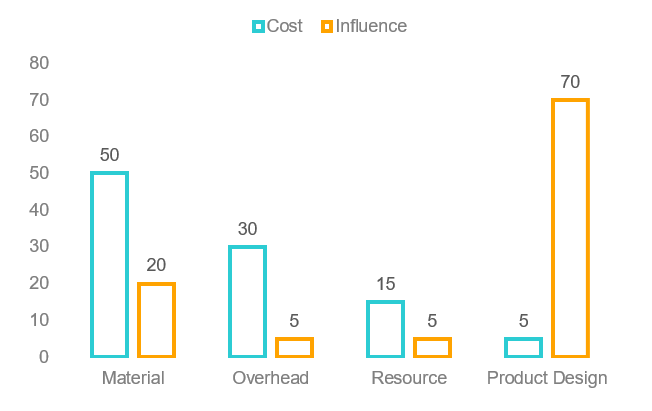

Oftentimes, there’s an inconsistency between the design goal and the outcome because without a simulation-driven design approach design teams are unable to balance product performance and accuracy with zero defects. Development factors like material costs, overhead, and production resources have an impact on bottom line costs, but not as much as product design does.

Minimizing design challenges begins with evaluating your current approach to product development. Traditionally, simulation, optimization, and validation has a longer lead time because of physical testing and over-designing. With simulation-driven design techniques, bridging the gap between goal and outcome can be achieved with early, up-front design changes and alleviating design errors at the beginning of the design cycle.

Using simulation to minimize design error

With the SimLab platform, modeling realistic product behaviors can be automated, making it easier to update designs at any point during development. By drastically reducing the time spent testing design proposals and correcting costly errors down the line, engineers and designers can redirect focus to product analysis and simulating their product under a wide variety of real-world use and abuse conditions. Durability and drop testing, electronics, thermal, and multiphysics analysis are just some of the advanced simulation capabilities SimLab has to offer.

Learn more at https://www.altair.com/simlab/.