Are Electric Vehicles Increasing the Risk of Structural Failure in Parking Garages?

The recent partial collapse of a parking garage in New York City (NYC) is sparking serious debate over aging infrastructure’s ability to meet the demands of today’s increasingly heavy automobiles. Some observers are suggesting that a rapid switch to electric vehicles (EVs) is posing a threat to the integrity of many older multi-level garages. But is there really any correlation between the issues highlighted by events in NYC and the growing number of vehicles fitted with 1,000+ pound lithium-ion batteries? And how might Altair’s latest simulation, lightweighting, and artificial intelligence (AI) solutions help designers prevent future building failures?

Will the increasing number of EVs on our roads lead to more structural failures in parking garages? That’s one of the questions circulating in the wake of the partial collapse of a four-story structure in Lower Manhattan. In April 2023, the top floor of a 1920s-era building on Ann Street, used as a parking garage for over 60 years, fell onto the floors below.1 In the ensuing debate, some are claiming that a growing number of EVs is increasing the risk for such incidents. And it all comes down to weight. In place of internal combustion engines (ICE), EVs rely on a lithium-ion battery for propulsion. Typically, these weigh in at 1,100 pounds or more. As a result, these vehicles are imposing greater force on infrastructure. Unless action is taken, the risk of further structural failures in concrete and/or steel-based buildings never designed with EVs in mind appears certain to increase. But is this the case? Or do the root causes of parking garage collapses lie elsewhere? Moreover, what tools are available to help designers ensure the integrity of both new and existing parking facilities? Let’s explore further.

The Heavy Load of Electrification

In the search for answers, the obvious starting point is a closer look at the impact of electrification on vehicle weight. Does replacing a gasoline-powered internal combustion engine with a battery-powered electric motor inevitably create a heavier vehicle? For the moment, the answer is yes – and it’s the battery that carries the weight. A lithium-ion battery’s energy density is significantly less than that of gasoline. It takes an extremely large battery to provide EVs with an acceptable range. For instance, the battery in GMC’s electric Hummer weighs in at 2,923 pounds. That’s more than the weight of an entire Ford Fiesta – a gas-powered vehicle – which is one of Europe’s best-selling cars. More typically, a sub-compact Chevrolet Bolt EV weighs 3,563 pounds, roughly 1,000-1,500 pounds heavier than a similarly sized Hyundai Accent with an internal combustion engine. A broader calculation by JATO Dynamics, a specialist automotive business intelligence firm, found that EVs generally weigh 10% more than their gas-powered counterparts. Another assessment from the International Council on Clean Transportation puts the figure at 16% for new models in Europe.2

Tipping Point Ahead

To better assess the potential risk EVs pose, we need to dig a little deeper. Right now, EVs account for less than 1% of the automobiles on American roads.3 McKinsey, a management consultancy firm, predicts this will increase to 15% by 2030.4 However, those responsible for designing parking garages will need to treat nationwide averages with caution. In certain parts of the U.S., including NYC, EV adoption is likely to outpace the national average. That means parking garages in those areas may need to hold a higher percentage of EVs.

Piling on the Pounds

So EVs are heavier, and their adoption is accelerating. But cars were already piling on the pounds long before electrification. According to the U.S. Environmental Protection Agency (EPA), the average car in the U.S. weighed 3,200 pounds in 1981. As of 2020, that figure stood at 4,166 pounds – nearly a 1,000-pound increase.5 It’s a similar story in Europe. Between 2001 and 2022, the average weight of cars sold there increased by 21%.6 In the latter part of the 20th century, this increase was largely the result of newly-added features. In more recent years, another factor stands out: the rise of the sport utility vehicle (SUV). Between 2010 and 2018, SUVs accounted for 60% of the increase in the global automobile fleet. In 2010, there were 35 million on the road. By 2018, there were 200 million.7 And since SUVs are roughly 22% heavier than sedans on average, it’s clear that EVs are simply part of a trend, not the start of one.8

Set in Stone?

To date, none of this seems to have impacted the metrics that underpin parking garage design in the U.S. Building codes have long recommended designing parking garage floors for live loads of 40 pounds per square foot. The term live loads, in this case, refers to loads that are subject to change based on the number and location of vehicles. Even in the aftermath of the NYC collapse, there’s no sign of imminent change. Presumably, designers and lawmakers feel current regulations offer sufficient safety margin to accommodate the transition not just from gas to electric, but also from sedans and wagons to SUVs and, to a lesser extent, pickup trucks, though examination is ongoing.

Moving with the Times

But that doesn’t hold true everywhere. In June 2023, the U.K.’s Institution of Structural Engineers, a professional body of engineers whose guidelines inform building codes, issued revised advice. In its own words, an updated version of the report “Design recommendations for multi-story and underground car parks” reflects “significant changes to vehicular size, weight and manoeuvrability.” Specifically, it specifies to increase the uniformly distributed load, which represents the vehicles’ weight impact, from 2.5kN/m2 to 3kN/m2,9 a 20% increase. At the launch of the new publication, Chris Whapples, a fellow of the Institution of Structural Engineers and the overseeing consultant for the team of experts who contributed to the new guidance, noted: “Car park safety is paramount, especially given the learnings from structural failures, including the floor collapse in Wolverhampton, U.K. in 1997. And this guidance is made increasingly relevant with the recent, tragic collapse of a car park in Manhattan, New York, which is currently being investigated.”10

Simulation: The Perfect Answer to “What if?”

Is there a way to predict how a parking garage, or any structure, will perform relative to its intended design? Today, engineers use sophisticated simulation tools like Altair® S FRAME® to make such predictions. With S-FRAME, users can virtually model, test, and validate structural designs to gain insight into how structures can and will behave in the real world.

In response to reporting that EVs might increase the likelihood of structural failures in parking garages, Altair engineers decided to simulate and test a concrete parking garage design using S-FRAME. First, the engineers created a virtual model of a multi-story concrete parking structure. Next, they tested the model under a range of loads. These included live-load magnitudes of 2.5kN/m2 and 3kN/m2. The first of these figures correlates to guidance provided in the now outdated edition of the aforementioned U.K. design code. The second is taken from the new version that increases the recommended load by 20%. The structure’s self-weight (weight of concrete) was also included in the analysis.

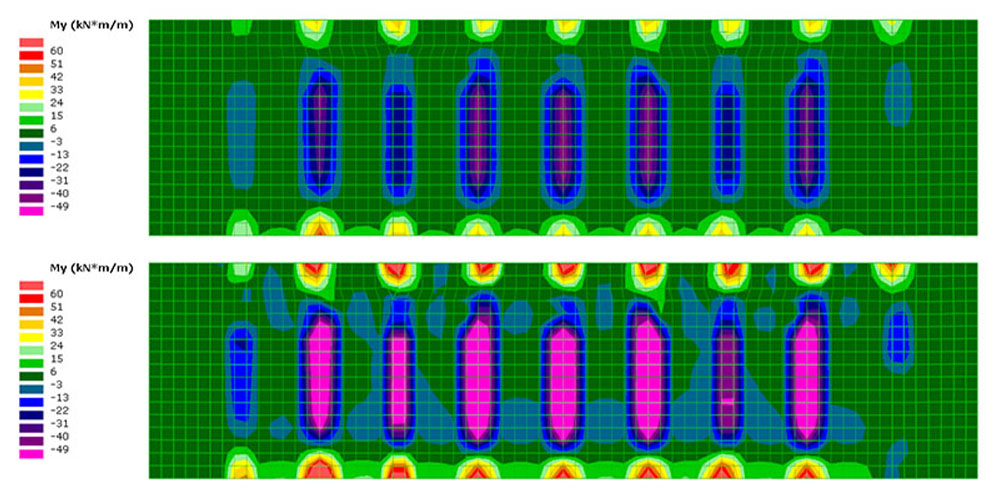

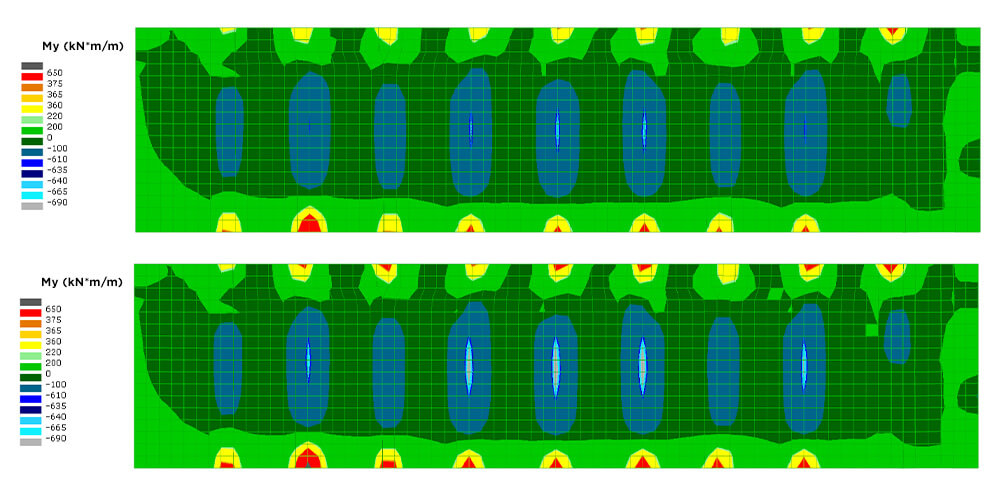

Figure 1 shows the garage model created for the analysis. Figures 2 and 3 provide a top-ramp view of selected simulation results to highlight the distributed load patterns on the concrete floor. Similar behavior patterns were exhibited throughout the model.

Viewed in isolation, the two results in Figure 2 appear to show that a 20% increase in the distributed live load has a dramatic impact. However, as Figure 3 demonstrates, when these loads are combined with the building’s self-weight, the overall load increase has a much smaller impact. For this concrete framed structure, the increase from 2.5kN/m2 to 3kN/m2 has a relatively insignificant impact on the overall structural design of the building. The key takeaway here is clear. Structural analysis and design solutions need to account for a much wider range of contributing factors than just vehicle weight. And they must reliably predict and ensure code compliance for “what-if” scenarios.

For structural engineers that need to revise loadings, simulation solutions such as S-FRAME and Altair® S-CONCRETE™ are invaluable. These intuitive tools enable designers to punch in different loadings and see immediately how the loads impact concrete and steel building design. Any number of “what if” scenarios can be run, testing design variations that might include shorter spans, stronger reinforcement, or larger parking bay sizes. Significantly, S-CONCRETE also supports reinforced concrete design with glass fiber reinforced polymer (GFRP), enabling designers to easily leverage an innovative material that’s lighter and offers better corrosion resistance than steel. As well as rapid assessment of design criteria, Altair’s solutions provide at-a-glance confirmation of compliance with relevant design codes.

The Bigger Picture

Of course, it's not just vehicle weight that’s growing. As a recent Vice article highlighted, the best-selling car in the U.S. in 1987 was a Ford Escort, which was around 13 inches narrower than the current chart-topper, the Ford F-150. Over the same period, the width of the vehicle reference size (aka the “design vehicle”) the parking industry uses has grown by a mere three inches.

The figures are based on an analysis of U.S. new car sales data undertaken every five years or so. But due to complex statistical quirks, the size of that design vehicle is hardly shifting. However, Carl Shneeman, a professional engineer and partner with Walker Consulting, a firm with extensive experience in parking projects, believes that bay sizes are still likely to grow: “If the vehicle is continuing to get wider, do we need to make an adjustment? I think we will.” 11

An uptick in standard bay size would mean fewer cars on each deck, adding another variable that designers might need to consider.

Supercharging Design Complexity

And the problems don’t stop there. Many garage operators are now looking to incorporate charging stations in parking bays. Adding to the complexity, the latest Tesla Supercharger v4 (complete with concrete footing) weighs more than 2,000 pounds. And in terms of safety, as more EVs hit the roads, parking garage designs may also need to address new fire hazards and other potential risks lithium-ion batteries pose.

Caring for the Older Generation

Advanced simulation will certainly speed the design of new structures that reflect a fast-changing world. But what about existing infrastructure? Official statements and media reports all point to numerous faults in the condition of NYC’s Ann Street building and, quite possibly, a number of unresolved building code violations. Deterioration, overloading, accidental damage, and other issues will all compromise a parking garage’s structural integrity. Unprotected steel reinforcement will corrode; at the Ann Street building, cracking and spalling (crumbling) concrete had been recorded as far back as 2003.

Adopting a Digital Twin

In NYC alone there are over 300 multi-story parking garages. More than 40 of them are as old, or even older, than the one on Ann Street. A local law introduced in 2021 now mandates professional inspections.12 Regardless of any potential impact from EVs, this is a sensible policy for any older concrete and steel building that houses parked cars. Faults should be addressed promptly, and buildings must be built and maintained per building codes. This is another area where innovative technology can mitigate risk.

Specifically, digital twins can help monitor building health. To date, this has tended to focus on major infrastructure such as bridges, and it’s not hard to see why. Bridges are subject to a wide variety of forces. What’s more, the collapse of Italy’s Morandi Bridge in 2018, which killed 43 people, underscored the potential consequences of failure.13 In the U.S., the Federal Highway Agency reports that one in three bridges needs either repair or replacement.14 By installing sensors to measure relevant data – such as strain, crack openings, temperature, etc. – and feeding this data via Internet of Things (IoT) solutions to a digital twin that leverages Altair’s simulation, data analytics and AI, and high-performance computing (HPC), teams can monitor the structural health of a bridge continuously and remotely.

Even more important, virtual sensors, also known as soft sensors, can be used to drive signal data from the physical sensors into predictive models. This Altair method reveals deeper performance insights that teams can leverage to reduce monitoring costs, enhance preventive maintenance, and boost safety.

Altair is a leader in digital twin technology and, in the not-too-distant future, it’s very possible this approach will be employed in parking garages. Initially, this would most likely be for large-scale facilities, like those located at airports or stadiums. In such a role, digital twins will enable the timely and cost-efficient assessment of any impact that heavier vehicles are having on the structure’s integrity.

Thinking Light

As with so many engineering challenges, people can also approach the EV weight from a completely different perspective. Instead of stronger parking garages, how about creating lighter vehicles? In recent years, lightweighting has emerged as a megatrend throughout the manufacturing sector. Automotive design fully depends on lightweighting to address demands for resource sustainability, carbon reduction, and extended battery range. However, within vehicle design, lightweighting is a very complex issue. Reducing weight can increase problems with noise, vibration, and harshness (NVH), which can compromise the user experience.

Electrification adds even more complexity. EV design requires a complete reimagining of vehicle architecture and major system components. Successful design outcomes depend on an integrated, multi-physics, multi-attribute approach. Altair’s electrification solutions facilitate such a simulation-driven process, combining solver and optimization technology to optimize structural design at the earliest possible opportunity. Beyond this, dedicated solutions such as Altair® e-Motor Director™ further support the multi-physics approach, addressing all variables and providing insight into the best possible trade-offs between technical requirements, safety, sustainability, performance, and comfort. With solutions like these, organizations can embed lightweighting in design workflows from the outset.

Changing the Batteries

As far as EV weight is concerned, the relationship between the battery, battery tray, and vehicle structure is particularly significant. Solutions like Altair® OptiStruct® enable design and engineering teams to test all options and parameters, and optimize topology well before committing to physical prototyping. Within the EV domain, this need for an integrated approach is evident in the latest developments, which include a new wave of cell-to-chassis designs. As the name suggests, the battery cells are integrated into the chassis itself. As a result, weight reduction is combined with better weight distribution, and the battery cells also contribute to chassis rigidity. Tesla’s Model Y, launched in 2022, is the first mass market EV to employ this technology. Other manufacturers are pursuing similarly novel techniques to reduce battery weight and increase energy density.

Predicting the Future

With several conflicting trends in motion, it’s hard to predict the future of EV design. Alongside lightweighting, consumer behavior will also influence EV design. Right now, preference for SUVs is as strong as ever. However, new trends and desires will emerge, producing vast amounts of data. Analyzing that data and identifying patterns in it before the patterns become apparent to the human eye is one of the key strengths of Altair® RapidMiner®, a tool that uses data analytics, prediction, and machine learning solutions to form yet another key strand in any automotive company’s portfolio. Altair RapidMiner’s capabilities provide data scientists and engineers with the earliest possible heads up on the need to change approaches to parking garage and EV design.

We're Only Human

Finally, amidst all the talk of technology, we shouldn’t overlook the age-old problem of human error. A 2017 article by Stan Caldwell, a structural engineer, cites a number of floor collapses in U.S. parking garages.15 Many were the result of overloading, albeit from activity such as construction work and snow clearance rather than regular car parking. A couple of years ago, Altair’s solutions supported an innovative robot car parking concept.16 Clearly, it would be a relatively straightforward process to delegate valet parking to such a robot (or autonomous driving feature). In conjunction with appropriate sensors, rules could be imposed to ensure that the weight of parked vehicles isn’t allowed to exceed the building’s design limits.

Ready for Anything

The future of EVs and their potential impact on parking garages is still the subject of debate. Right now, the evidence suggests they don’t present an imminent risk to building integrity. However, if the current trend of rising vehicle weight continues and the menace of building neglect combined with aging parking garages persists, there will certainly be grounds for concern. The good news is that with the availability of modern simulation, lightweighting, and AI solutions that easily integrate into design workflows, teams can gain the insight needed to address these issues faster and more efficiently than ever.

1. 1 person is dead after a parking garage collapses in New York City : NPR (archive.org)

2. https://uk.motor1.com/news/622233/obesity-of-cars-new-industry-challenge/

3. https://www.reuters.com/graphics/AUTOS-ELECTRIC/USA/mopanyqxwva/

5. https://www.epa.gov/sites/default/files/2021-01/documents/420r21003.pdf

6. https://uk.motor1.com/news/622233/obesity-of-cars-new-industry-challenge/

8. https://uk.motor1.com/news/622233/obesity-of-cars-new-industry-challenge/

9. https://www.istructe.org/resources/guidance/car-park-design/

10. https://www.istructe.org/resources/news/car-park-design-needs-to-evolve-to-cope-with-bigger, heavier electric cars - The Institution of Structural Engineers (istructe.org)

11. https://www.vice.com/en/article/y3pyzx/american-cars-are-getting-too-big-for-parking-spaces

12. https://www.nytimes.com/2023/05/15/nyregion/nyc-garage-collapse.html

13. https://www.bbc.co.uk/news/world-europe-65684334