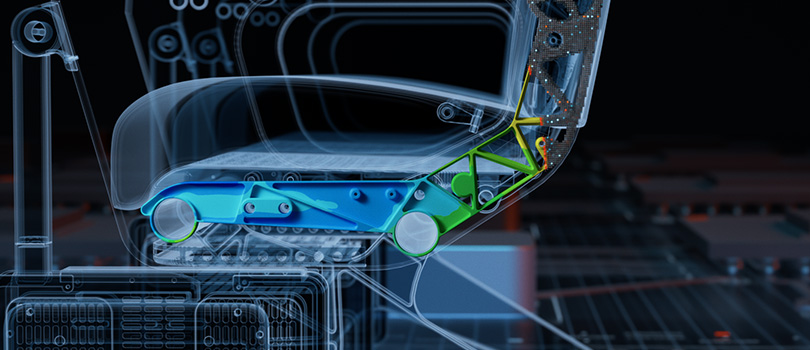

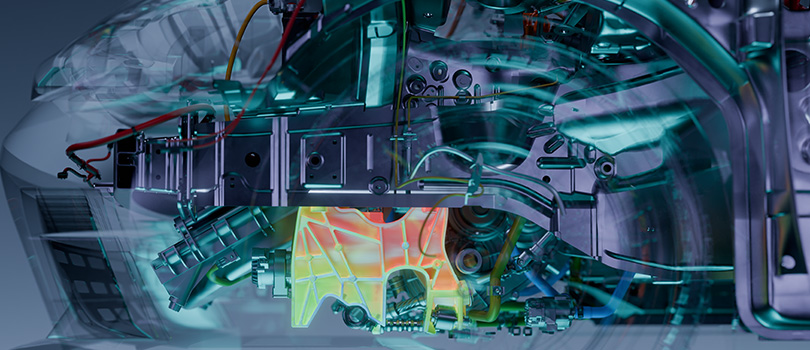

Faster Model Build and Assembly for Enterprise-Scale Simulation

Engineering teams can now handle large, complex assemblies with speed and fluidity, shortening build and validation cycles for enterprise-scale models.

- Large and complex assemblies now load and update almost instantly, eliminating long waits during model preparation.

- Model building, meshing, and connector creation are significantly faster, reducing setup time for detailed structures.

- Integrated data management keeps models consistent with shared standards across teams and programs.

- New navigation and editing tools maintain smooth performance even with massive assemblies.