5 Ways to Optimize Your Design

Have you ever felt like your design was overweight or unnecessarily exceeded its structural requirements? This could mean you are using excessive material which can directly affects the overall cost.

Or has your single part been patched up with structural Band-Aids so many times due to ever-changing requirements that it has become an inefficient, overweight monster? This could mean your casting or molding is in dire need of ribs, but you don’t know where they should be placed.

Or have you often sat wondering what the right combination of gauges is for your complex assembly in order to find the optimal balance between weight and performance? Perhaps you’re starting from a clean slate? You know the space available and the structural requirements to meet but you're just not sure what the optimal architecture would be or even where to begin drawing?

Need a solution to circumvent these situations? Altair OptiStruct is a finite element-based tool that creates lightweight efficient designs through an iterative process.

Identifying which areas to modify when considering multiple, often conflicting, loading scenarios can be overwhelming and tedious. Sometimes, whether from a faulty inception or due to multiple evolutions during its life, the structure does not follow the main load paths. This makes the design automatically, not optimal.

Using the various techniques in Altair OptiStruct, we will take a simple, clearly over-designed, tubular structure and optimize it to reduce material and cost. These concepts can be utilized on your own designs, both simple or complex.

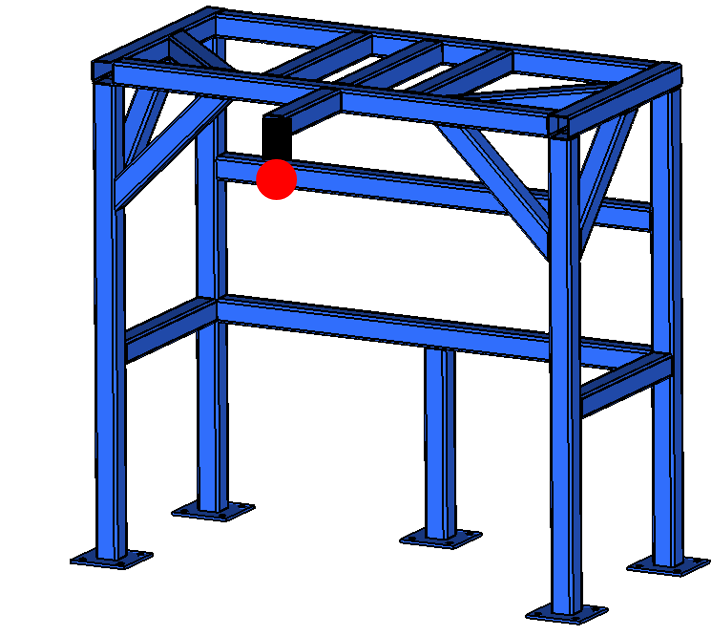

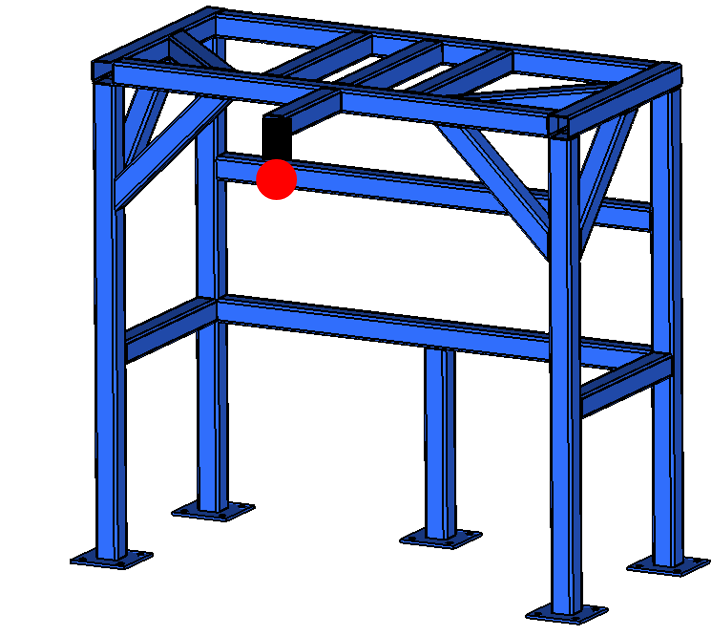

The structure we are using is made up of standard 2“x2”x0.12” tubes welded together to support a 440-lbs mass (shown in red) from the front overhanging tube. It’s supposed to withstand gravity loads, in various directions, with deflection requirements. It is bolted to the floor at five locations.

The current design weighs about 130lbs and easily meets the deflection requirements. Don’t you think this structure is slightly overdesigned? Let’s see what design iteration OptiStruct can perform for us.

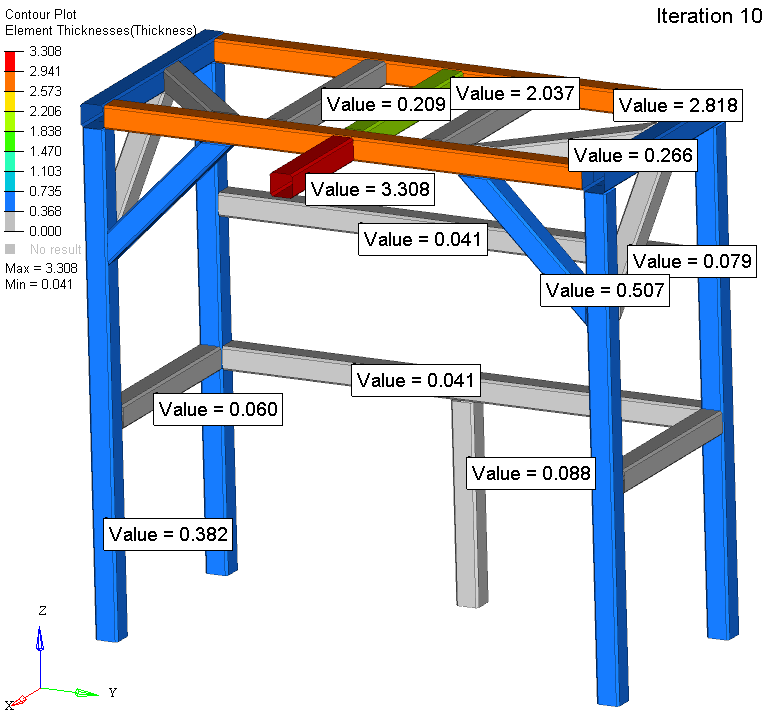

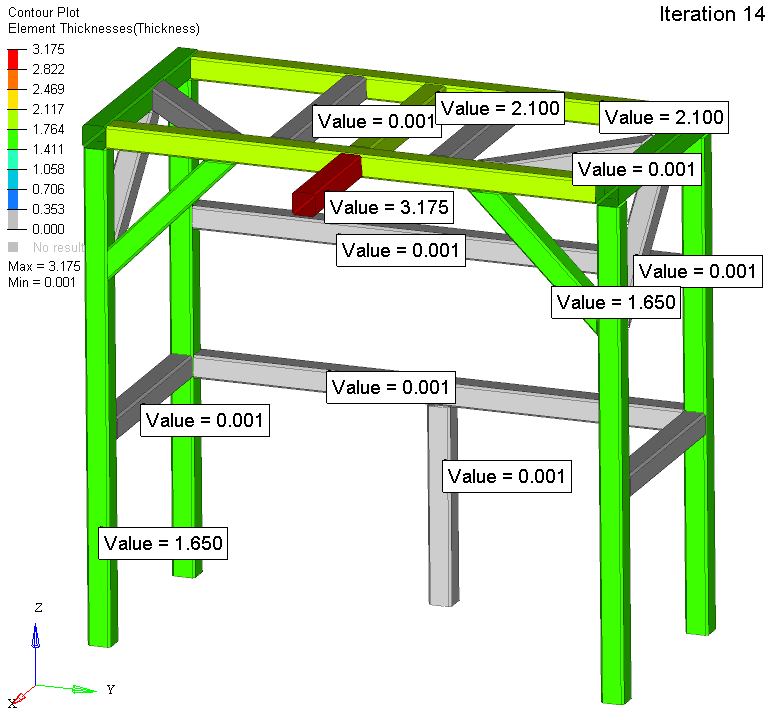

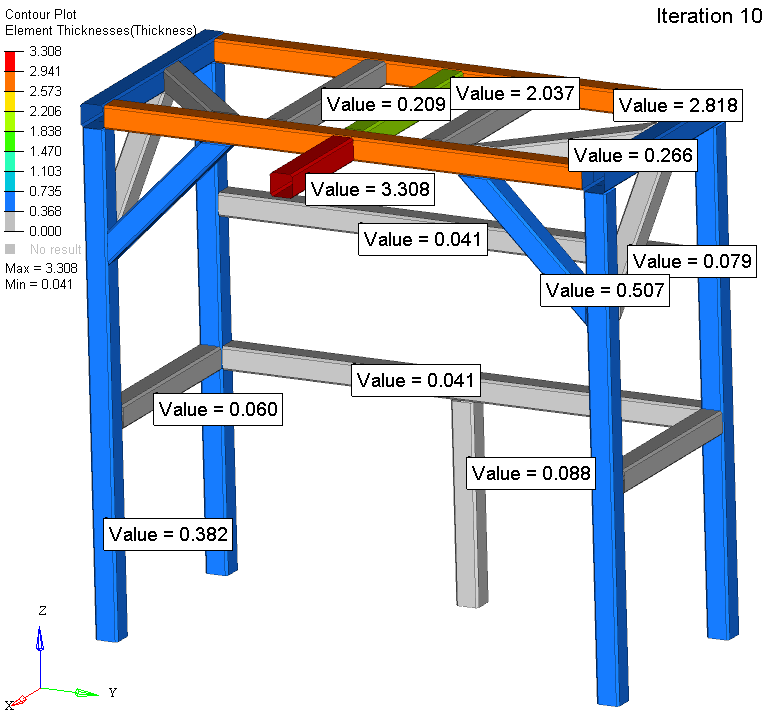

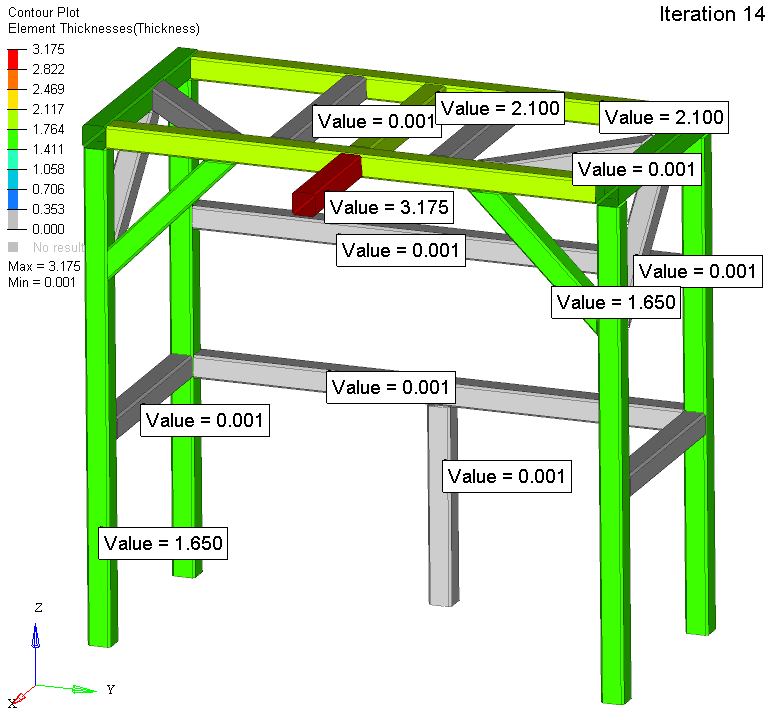

This picture below shows the outcome of the gauge optimization with the total mass of the structure being under 33lbs. (thickness in mm, starting from 3mm in the original design)

The tubes in grey show a very low thickness which indicate they can be removed. The lower fifth support is eliminated as well as some of the redundant tubes in the upper half of the structure.

However, the results are not easily obtainable and would require special order tubes.

Taking this into account, a new analysis was conducted by limiting the gauges to a few standard values. The new results put the total weight of the structure under 48 lbs. With the new constraints, the mass increase from the previous analysis is a logical outcome because this constraint has removed design freedom from the optimization problem.

We start with the original structure and tube gauges and the 22 lbs structure shown below highlights the areas that are and are not necessary to the design. Considering the gauge optimization already preformed, these results correlate well.

It is difficult to create this structure with tubes because some sections are incomplete in areas, but this provides valuable information to the user about the lightest design available that will still meet all the structural requirements.

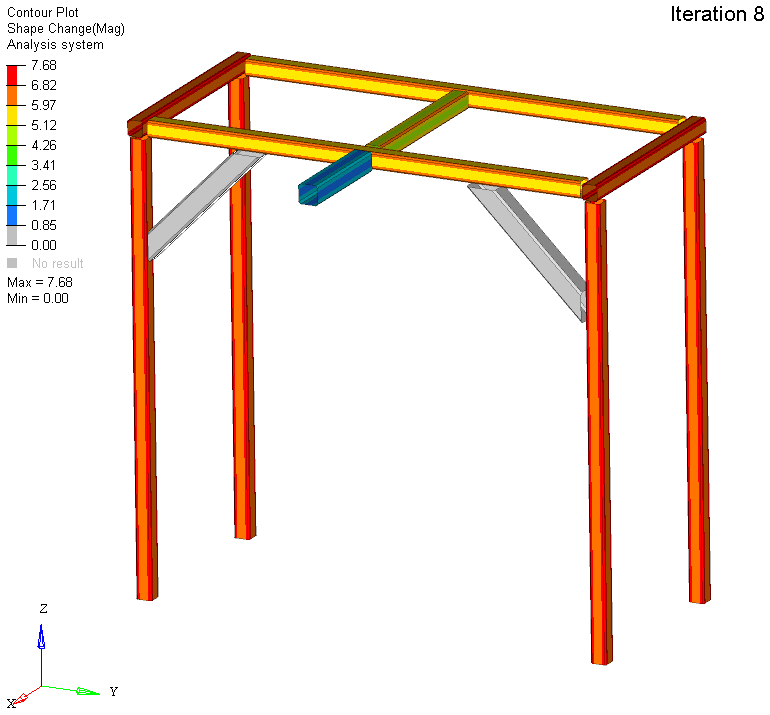

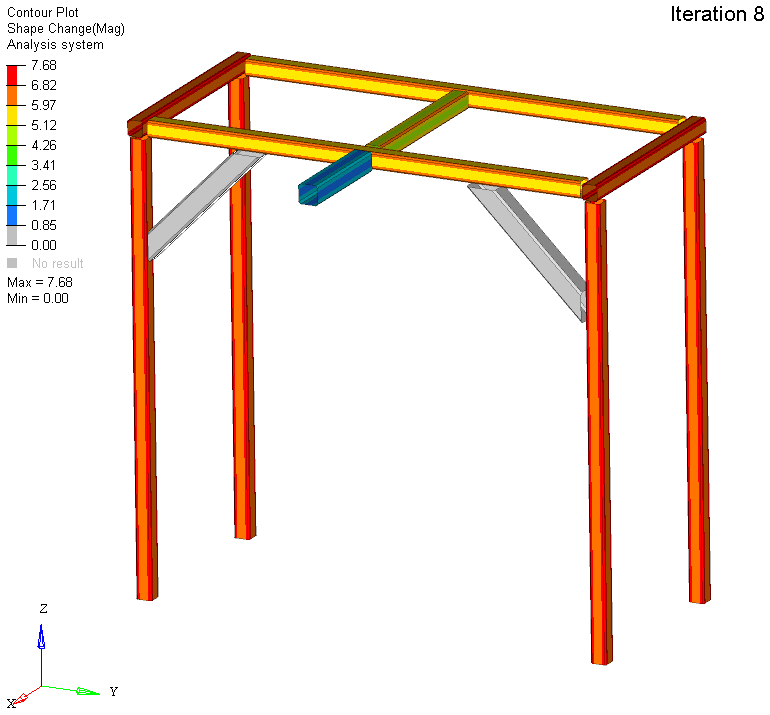

The picture below shows how much the sections have grown in either direction to determine the lightest structure (about 60 lbs) that meets the requirements.

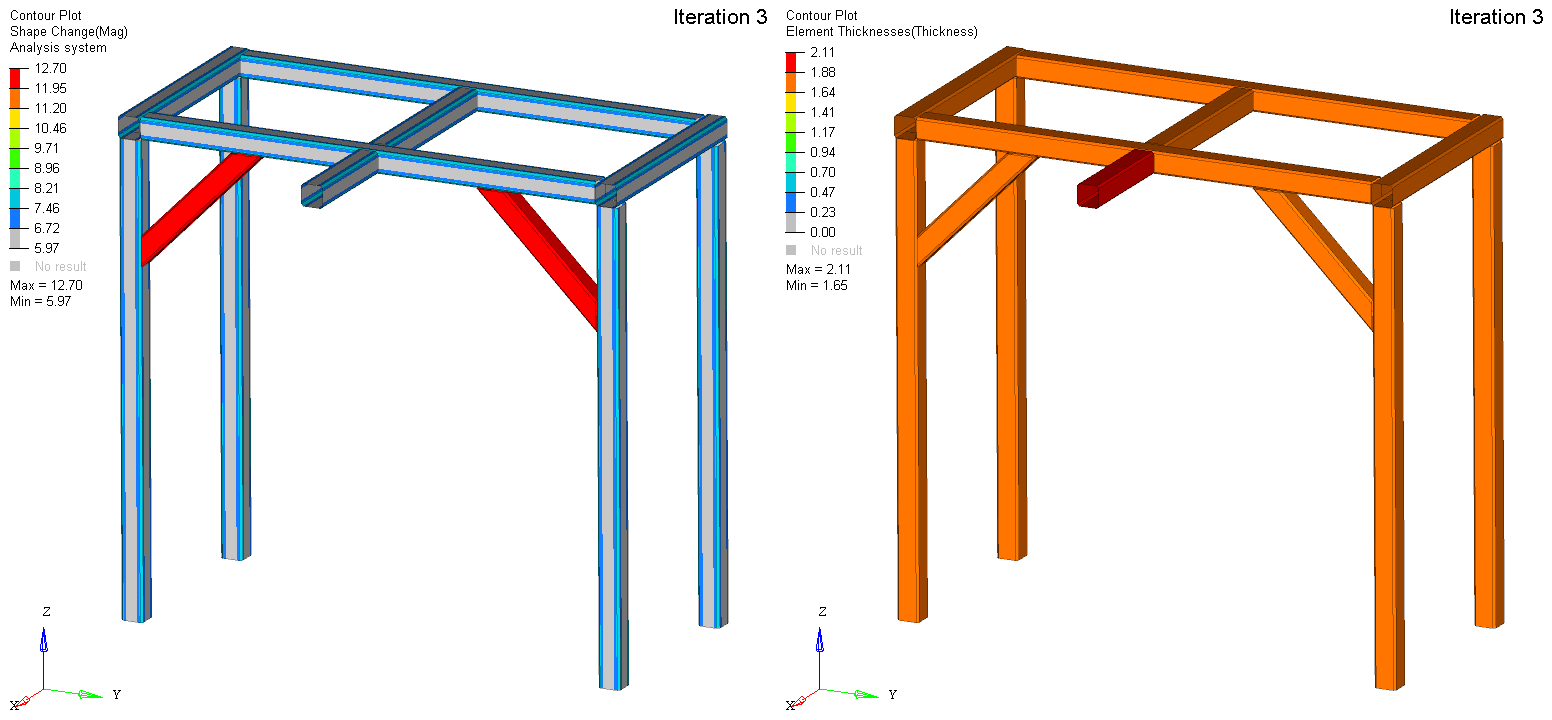

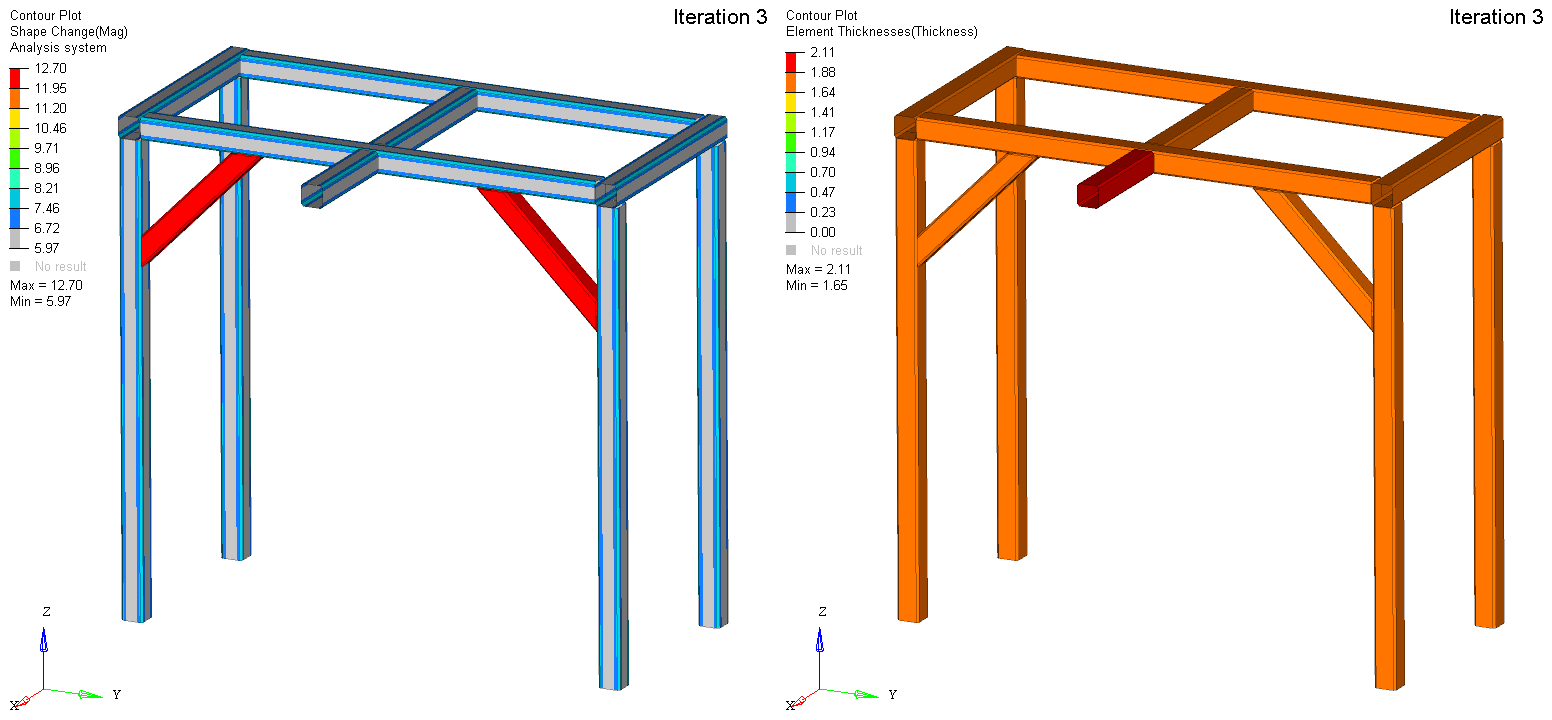

In size and shape analysis, parameters can be set to force the structure to use standard sized cross-sections and varying the gauges can also be added to the analysis for a more accessible solution. This picture shows the shape change on the left and the thickness value on the right for a final solution to the comprehensive size and shape optimization.

This type of optimization can be used for many geometric parameters other than tube cross-sections.

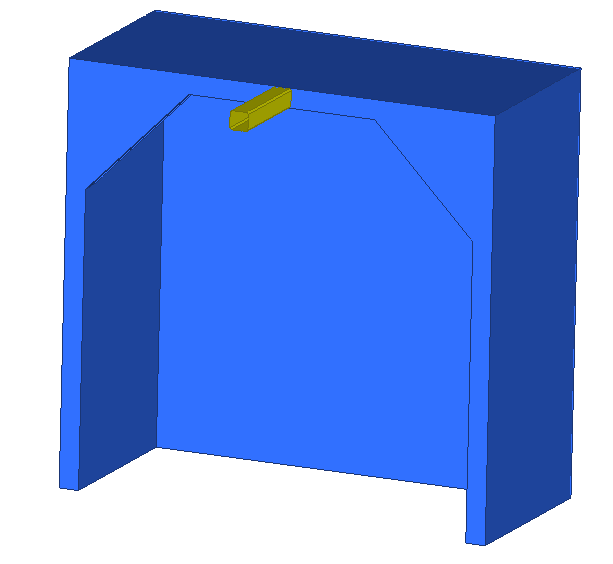

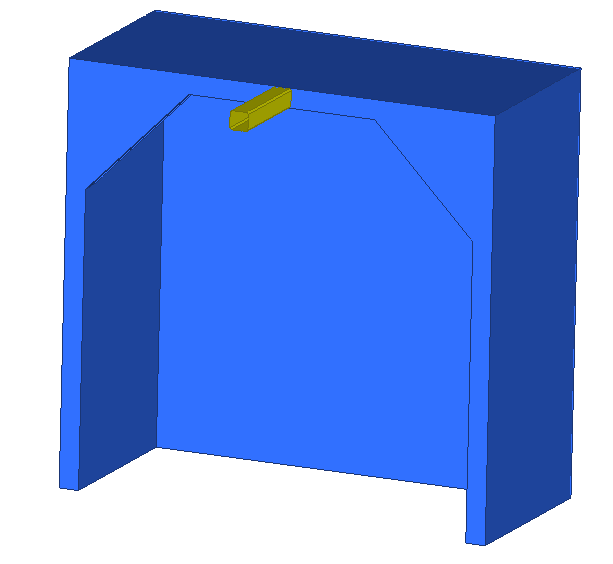

For the considered structure, the design space is shown in blue. The inside of the structure was left open, just like the original design. The overhanging tube was excluded from the 3D topology optimization, as it does not affect the overall load-paths.

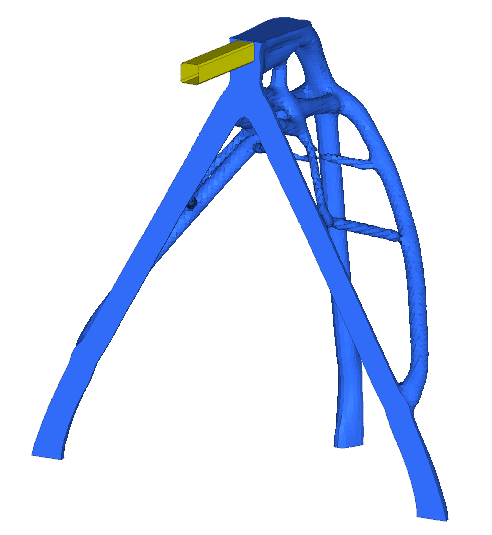

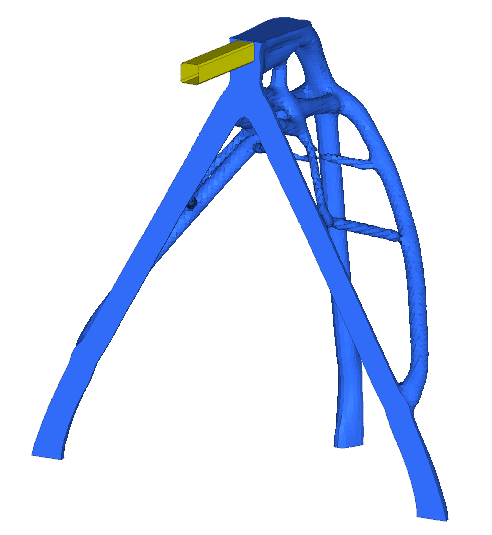

During the analysis, 3D topology optimization carves out the unnecessary material, only showing the main load-paths of the structure.

These results match up with the previous gauge optimization because Altair OptiStruct has removed unnecessary tubes. It also shows a unique, more optimal, design of the sides of the structure. The mass of this structure is not relevant until the material layout is interpreted into a manufacturable design.

These results match up with the previous gauge optimization because Altair OptiStruct has removed unnecessary tubes. It also shows a unique, more optimal, design of the sides of the structure. The mass of this structure is not relevant until the material layout is interpreted into a manufacturable design.

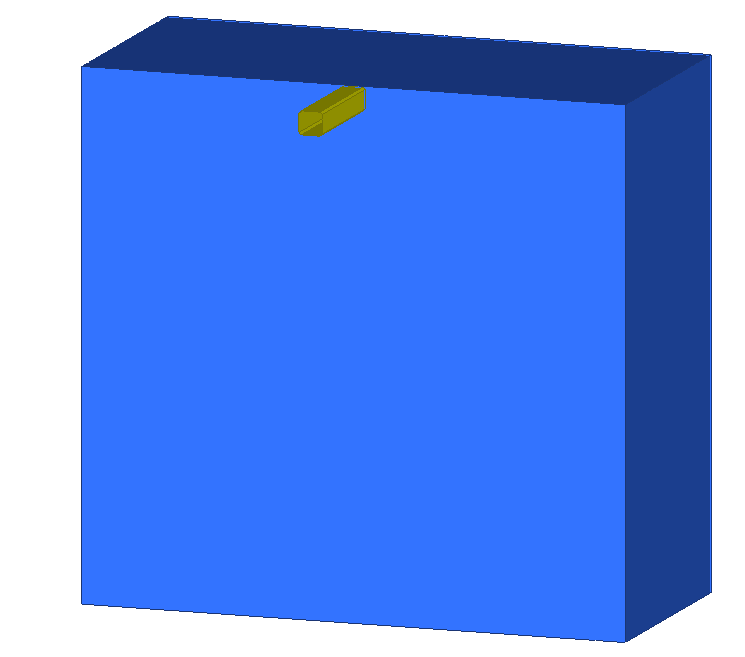

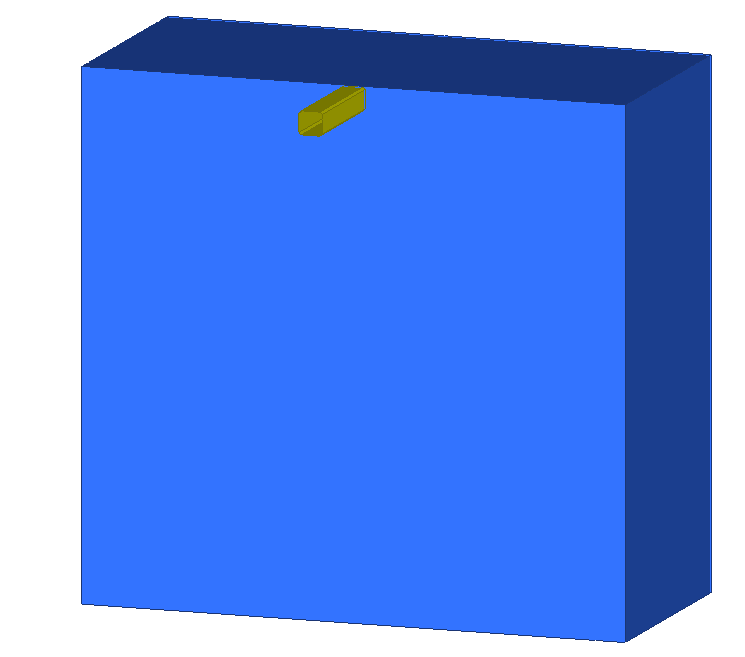

If the design space in blue is modified to include the inside area that was left out in the previous analysis, a different material layout can be obtained.

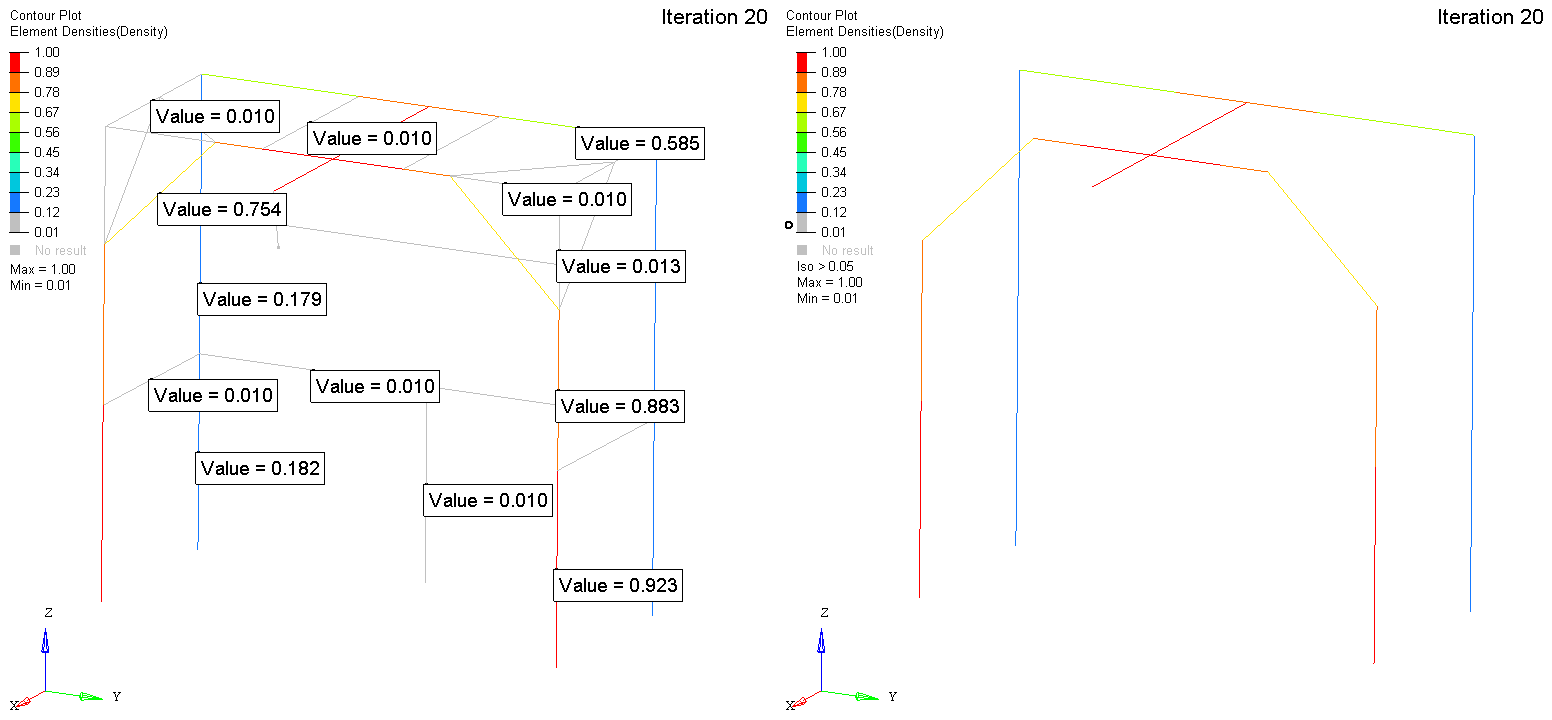

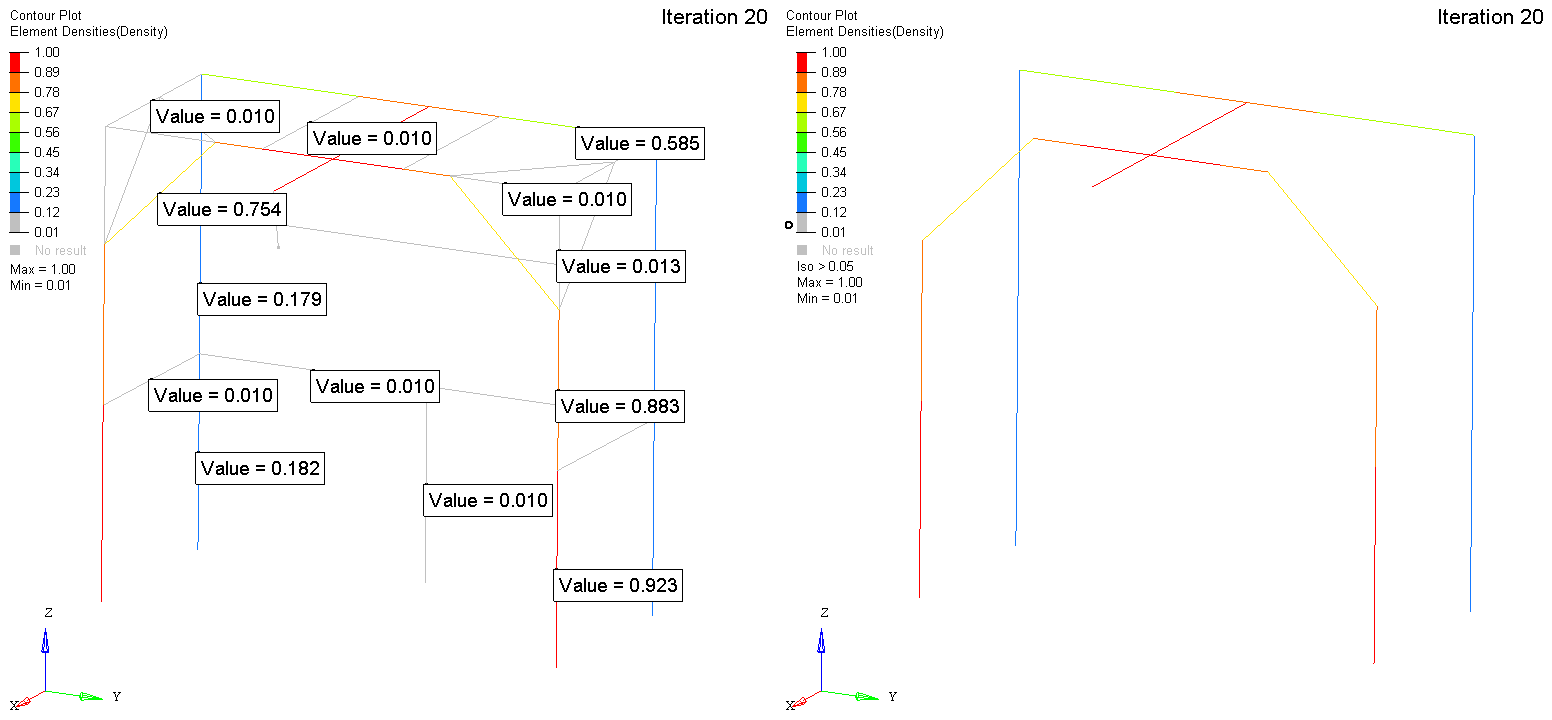

The outcome of a 1D topology optimization shows density values indicating the necessity of a tube for the overall structure. These values can be seen on the left and while the right shows all the required beams isolated. The lower the value is, the more unnecessary the beam is.

The results of this 1D optimization are compatible to the results seen in the previous analyses. Both the overall layout design and the removal of unnecessary beams appear in each of the results thus far.

Gauge optimization, size and shape, and shell optimization, can be used to improve an existing design without altering its overall architecture. 3D topology optimization can be used when a significant re-design is desired because it identifies the optimal load paths of a structure and recommend material reduction. The material layout produced in the 3D topology is then interpreted into a concept design which is dimensioned and fine-tuned with the gauge, size, and shape approaches resulting in a final structure.

Within Altair HyperMesh and Altair OptiStruct there are many other optimization techniques not covered above that can be leveraged in the design process.

Topography optimization allows you to design bead features on the surface of the design, which is a great way of tuning a localized stiffness. Multi-material optimization allows you to distribute different materials across an assembly to optimize stiffness, strength, and weight. Design exploration and optimization through Altair HyperStudy can be used to evaluate many different designs parameters and extract an optimal combination.

All techniques have potential for optimizing a design, but each have a place in the design process. For example, size and shape optimization (including gauge) should not be initiated until the material layout is known and this is usually done through 3D topology optimization.

Learn more about Altair OptiStruct and download the step-by-step tutorials!

Or has your single part been patched up with structural Band-Aids so many times due to ever-changing requirements that it has become an inefficient, overweight monster? This could mean your casting or molding is in dire need of ribs, but you don’t know where they should be placed.

Or have you often sat wondering what the right combination of gauges is for your complex assembly in order to find the optimal balance between weight and performance? Perhaps you’re starting from a clean slate? You know the space available and the structural requirements to meet but you're just not sure what the optimal architecture would be or even where to begin drawing?

Need a solution to circumvent these situations? Altair OptiStruct is a finite element-based tool that creates lightweight efficient designs through an iterative process.

Identifying which areas to modify when considering multiple, often conflicting, loading scenarios can be overwhelming and tedious. Sometimes, whether from a faulty inception or due to multiple evolutions during its life, the structure does not follow the main load paths. This makes the design automatically, not optimal.

Using the various techniques in Altair OptiStruct, we will take a simple, clearly over-designed, tubular structure and optimize it to reduce material and cost. These concepts can be utilized on your own designs, both simple or complex.

The structure we are using is made up of standard 2“x2”x0.12” tubes welded together to support a 440-lbs mass (shown in red) from the front overhanging tube. It’s supposed to withstand gravity loads, in various directions, with deflection requirements. It is bolted to the floor at five locations.

The current design weighs about 130lbs and easily meets the deflection requirements. Don’t you think this structure is slightly overdesigned? Let’s see what design iteration OptiStruct can perform for us.

1. Gauge Optimization

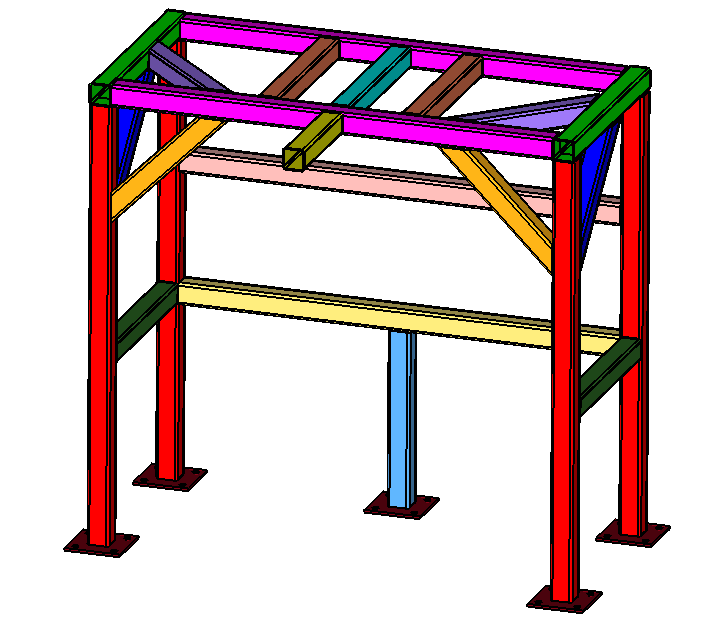

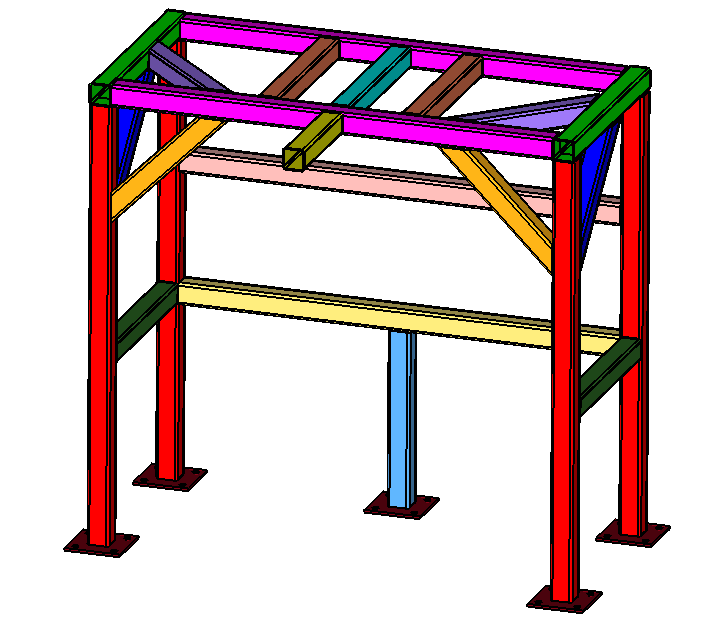

Gauge optimization will determine the lightest combination of gauges that meet the requirements of the structure. To respect the symmetry in the architecture, the tubes are grouped by different colors and the gauge of each group can vary. The base plates are excluded from the optimization as they do not contribute to the structure’s performance.

This picture below shows the outcome of the gauge optimization with the total mass of the structure being under 33lbs. (thickness in mm, starting from 3mm in the original design)

The tubes in grey show a very low thickness which indicate they can be removed. The lower fifth support is eliminated as well as some of the redundant tubes in the upper half of the structure.

However, the results are not easily obtainable and would require special order tubes.

Taking this into account, a new analysis was conducted by limiting the gauges to a few standard values. The new results put the total weight of the structure under 48 lbs. With the new constraints, the mass increase from the previous analysis is a logical outcome because this constraint has removed design freedom from the optimization problem.

2. Shell Topology Optimization

Shell topology optimization will identify the areas of the existing tubes that can be eliminated and still meet the structural requirements.We start with the original structure and tube gauges and the 22 lbs structure shown below highlights the areas that are and are not necessary to the design. Considering the gauge optimization already preformed, these results correlate well.

It is difficult to create this structure with tubes because some sections are incomplete in areas, but this provides valuable information to the user about the lightest design available that will still meet all the structural requirements.

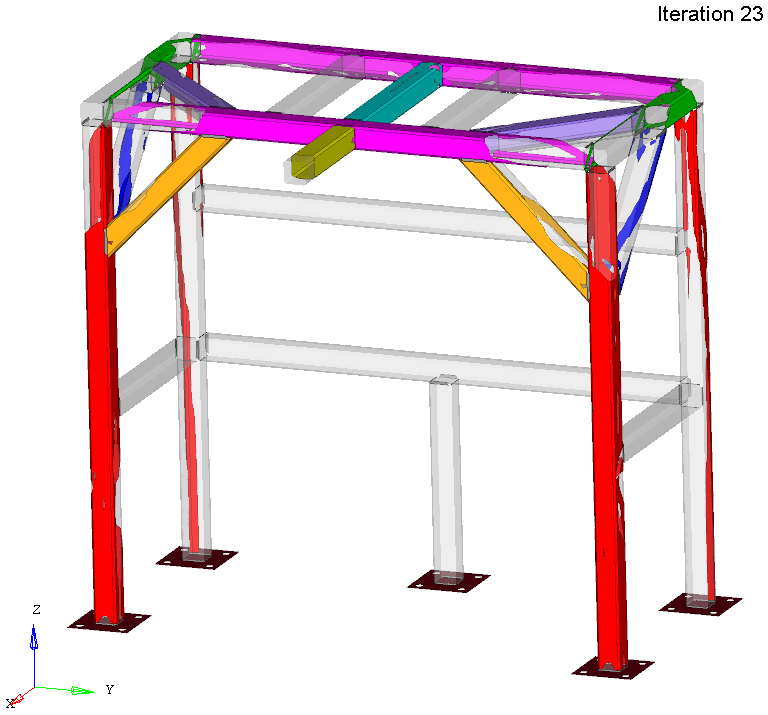

3. Size and Shape Optimization

Size and shape optimization allows users to modify some parameters of the geometry to reach a more optimal design. Within the tubular structure, the cross-section of each tube can be modified in size, adjusting the overall dimensions, and shape, changing the tube to be square, rectangular, horizontal or vertical.The picture below shows how much the sections have grown in either direction to determine the lightest structure (about 60 lbs) that meets the requirements.

In size and shape analysis, parameters can be set to force the structure to use standard sized cross-sections and varying the gauges can also be added to the analysis for a more accessible solution. This picture shows the shape change on the left and the thickness value on the right for a final solution to the comprehensive size and shape optimization.

This type of optimization can be used for many geometric parameters other than tube cross-sections.

4. 3D Topology Optimization

Sometimes it’s possible to completely re-design the architecture of the structure and start from a clean slate. 3D topology optimization will identify the optimal load-paths from the design space available based on the loading scenarios set and the defined constraints.For the considered structure, the design space is shown in blue. The inside of the structure was left open, just like the original design. The overhanging tube was excluded from the 3D topology optimization, as it does not affect the overall load-paths.

During the analysis, 3D topology optimization carves out the unnecessary material, only showing the main load-paths of the structure.

These results match up with the previous gauge optimization because Altair OptiStruct has removed unnecessary tubes. It also shows a unique, more optimal, design of the sides of the structure. The mass of this structure is not relevant until the material layout is interpreted into a manufacturable design.

These results match up with the previous gauge optimization because Altair OptiStruct has removed unnecessary tubes. It also shows a unique, more optimal, design of the sides of the structure. The mass of this structure is not relevant until the material layout is interpreted into a manufacturable design.If the design space in blue is modified to include the inside area that was left out in the previous analysis, a different material layout can be obtained.

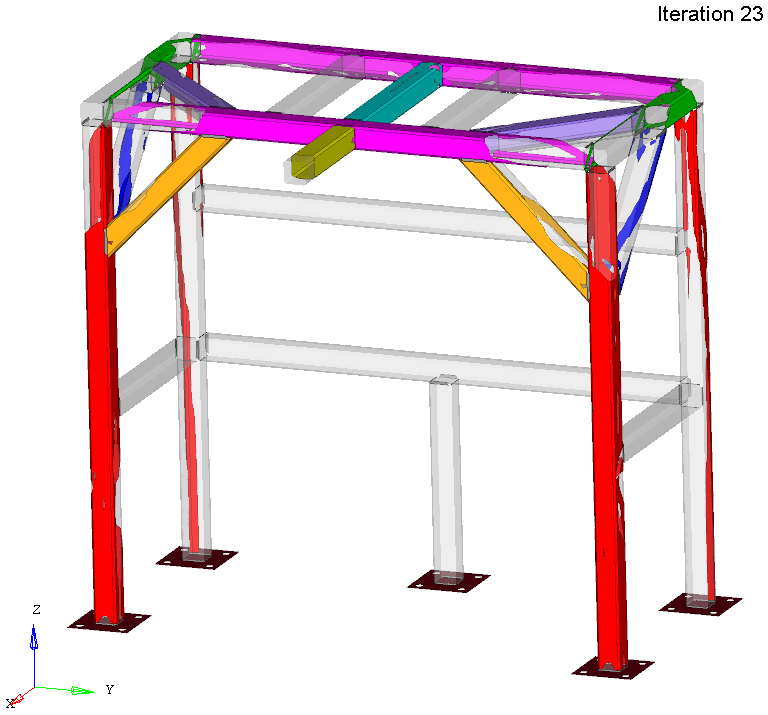

5. 1D Topology Optimization

To speed up analysis time, the structure can sometimes be modeled with 1D beam elements.The outcome of a 1D topology optimization shows density values indicating the necessity of a tube for the overall structure. These values can be seen on the left and while the right shows all the required beams isolated. The lower the value is, the more unnecessary the beam is.

The results of this 1D optimization are compatible to the results seen in the previous analyses. Both the overall layout design and the removal of unnecessary beams appear in each of the results thus far.

And then more…

All the above techniques illustrate some of the approaches that can be used to optimize a structure into a lightweight, efficient design that meets all structural requirements.Gauge optimization, size and shape, and shell optimization, can be used to improve an existing design without altering its overall architecture. 3D topology optimization can be used when a significant re-design is desired because it identifies the optimal load paths of a structure and recommend material reduction. The material layout produced in the 3D topology is then interpreted into a concept design which is dimensioned and fine-tuned with the gauge, size, and shape approaches resulting in a final structure.

Do you want to learn how to execute all the techniques mentioned? Step-by-step tutorials are available now for download

Topography optimization allows you to design bead features on the surface of the design, which is a great way of tuning a localized stiffness. Multi-material optimization allows you to distribute different materials across an assembly to optimize stiffness, strength, and weight. Design exploration and optimization through Altair HyperStudy can be used to evaluate many different designs parameters and extract an optimal combination.

All techniques have potential for optimizing a design, but each have a place in the design process. For example, size and shape optimization (including gauge) should not be initiated until the material layout is known and this is usually done through 3D topology optimization.

Learn more about Altair OptiStruct and download the step-by-step tutorials!