Types of Lattices for Additive Manufacturing – Terms Engineers Need to Know

What types of lattices for additive manufacturing (AM) are there, and why are they so important? One of the advantages of AM is the ability to create fine-featured high-precision shapes, and many designers have taken advantage of this and added lattice or cellular structures to their components. These structures can extend the capabilities of the part beyond what’s possible using traditional manufacturing methods.

Let’s explain the terminology that AM engineers use when referring to lattice structures.

What is a Lattice Structure Using AM Techniques?

We define lattice structures as meso-level design elements consisting of repeating unit cell elements in 3D space. With AM, lattices bring many advantages. They reduce an object’s mass, which means less material is used. Cellular structures can also give objects extra strength. You can see this concept in nature, such as cork, sea urchins, honeycomb, and trabecular bone.

Lightweight, strong designs such as lattices reduce production costs, fuel use, and material waste. They have a host of other benefits as engineers move toward more optimized structures and begin to overcome the difficulties initially seen in their production.

Three Common Families of Lattice Structures

Lattice structures are incredibly important across all industries because they can be used to shape the physical properties of a part. There are three types of lattices for AM. These are different subsets of lattice structures that should be used depending on the properties you’re trying to achieve.

The three most common families of lattice structures are:

- Surface-based lattices – lattices that are generated from trigonometric equations. Modifying the equation controls the shape, size, and density of the 3D structure.

- Strut lattices – structures that consist of a series of rod-like forms that are connected in different orientations to form the different unit cells of the lattice.

- Planar-based lattices – structures created as a periodic pattern in a 2D plane and then extruded in a single direction to create the 3D structure

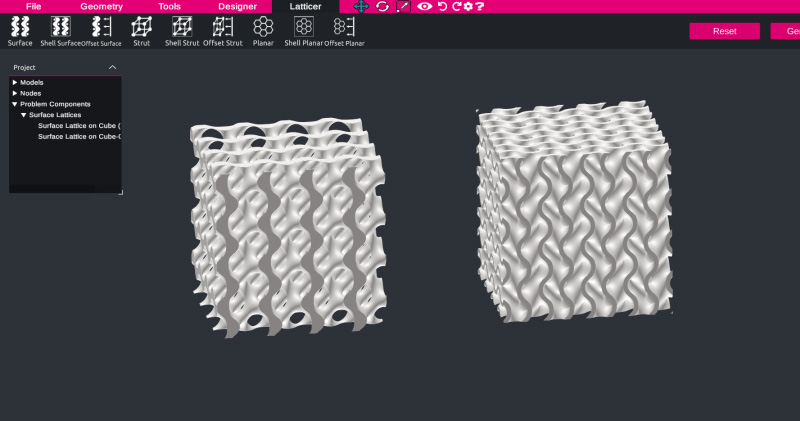

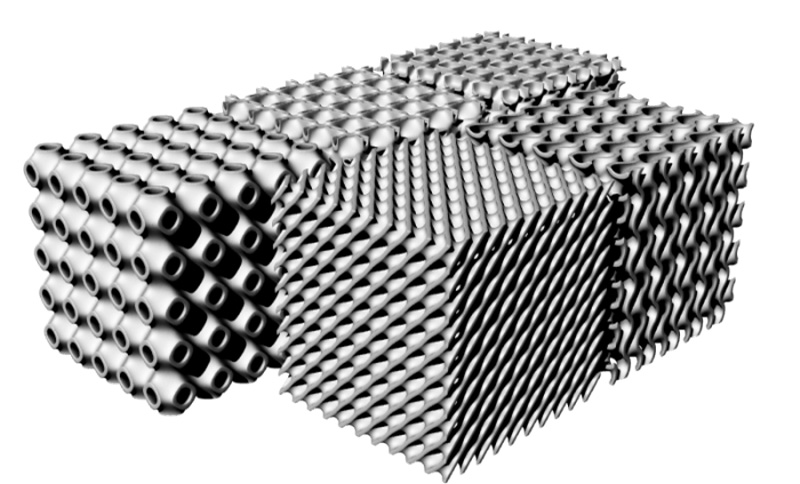

Examples of three different lattice families. On the left, we have surface-based lattices, in particular TPMS surfaces. In the center, we have a strut-based lattice and on the right, we see a planar or 2.5d lattice.

Surface-Based Lattices

A subset of surface-based lattices are triply periodic minimal surfaces (TPMS). TPMS structures are defined using equations. A famous example is the gyroid lattice structure, which can be seen in the figure above. The gyroid structure is defined using the following equation: sin(x)cos(y) + sin(y)cos(z) + sin(z)cos(x)=0.

TPMS Structures

TPMS structures come in two different forms, these are known as sheet and skeletal-based surface lattices. Each of the TMPS lattices can be modified to have these forms and they can be created by toggling the double skin checkbox within Altair Altair Sulis. The sheet and skeletal versions of TPMS lattices can be used for different purposes, these can include bioscaffold for the skeletal-based lattice, and the high surface area to volume ratio of the sheet-based TPMS structures makes them ideal for thermal management applications.

Two types of TPMS gyroid lattice. The left lattice is a skeletal version, and the right is a sheet version of the gyroid structure.

By modifying the equation different structures can be created. Over the years, researchers and mathematicians have derived many different structures based on this format.

Examples of different TPMS gyroid structures created in Altair Sulis. These can be created by manipulating the trigonometric functions.

Strut-Based Lattices

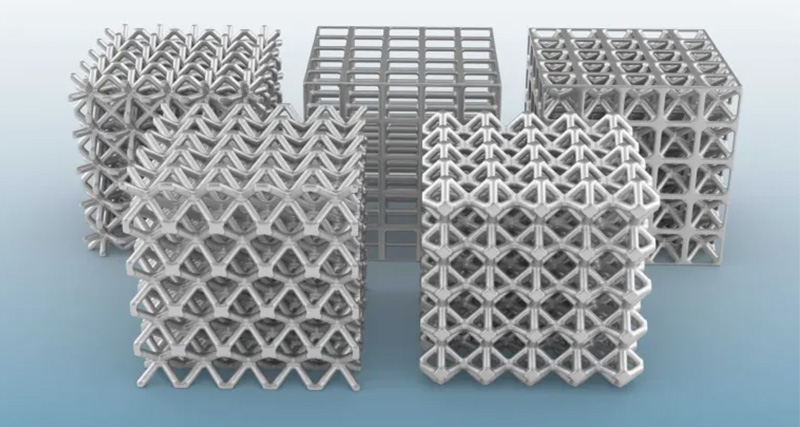

The next family of lattice structures are strut-based lattices. These are structures that consist of a series of rod-like forms that are connected in different orientations to form the different unit cells of the lattice. Some examples of these structures, created with Sulis, can be seen in the figure below.

A range of strut-based lattice structures compromising different unit cell types.

As you can see, the way that the rods are connected can have a significant effect on the mechanical properties of the lattice structure. Traditionally, strut-based lattices have been the most common type of lattice structure. However, designing correctly with strut-based lattices can be challenging.

Periodic and Stochastic Lattice Structures

The way the rods are connected also gives us another descriptor for strut-based lattices. Some lattices have the same repeating unit cell throughout the entire part. These are known as periodic lattices. The alternative to this is where the cells are connected randomly throughout the global structure. These are called stochastic lattice structures.

Stochastic lattices are commonly used in biomedical applications since they can be designed to closely resemble the properties of human bone and are excellent at reconnecting bone structures inside the body.

Periodic vs stochastic lattice structures. The left lattice shows a uniform periodic lattice structure made up of the same repeating unit cell. On the right, we can see a stochastic lattice with randomness built into the direction and structure of the struts.

Planar-Based Lattices

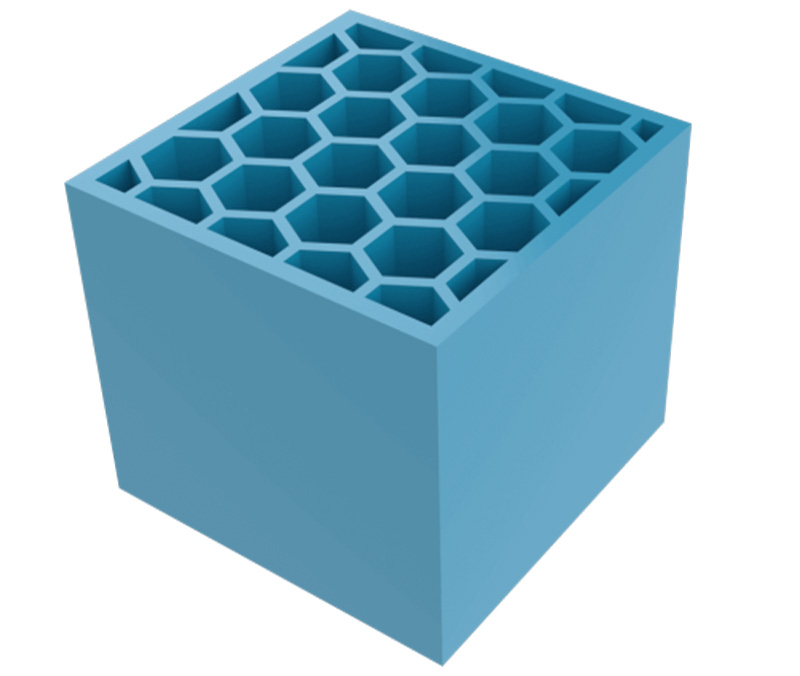

The final category of meso-level design elements consisting of repeating unit cell elements in 3D space is the planar lattice. This can sometimes also be referred to as 2D or 2.5D lattices. These structures are created as a periodic pattern in a 2D plane and then extruded in a single direction to create the 3D structure. An example can be seen in the following figure.

An example of a planar lattice structure.

These structures are extremely useful when designing for minimal material usage – one of the four key principles of design for additive manufacturing – because they can be used wherever bulk material is present to reduce the mass and material required to print a part.

Planar lattices are the simplest type of lattice structure and can typically be created using any traditional CAD software as a BREP model. Sulis can be used to create these types of structures for more complex shapes. You can see how planar lattices can be used to remove material and create an aesthetically pleasing part in this design tutorial.

Are All Lattices Uniform?

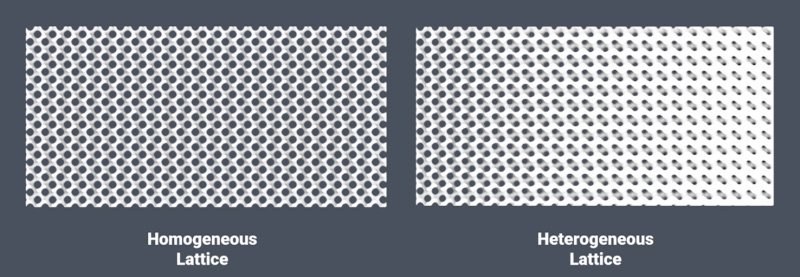

We’ve covered the basics terminology describing the different lattice families. However, these are still a couple more important terms that you need to know. Firstly, we need to describe whether the lattice is the same or changing through the part. To describe this, we introduce the terms homogeneous and heterogeneous lattices.

Homogenous Lattice Structures

A homogeneous lattice structure has uniform lattice properties across the entire part. Conversely, with a heterogeneous lattice structure, one or more of the lattice properties are changing. Common properties that users can decide to change include the unit cell’s density, wall thickness, and size.

Examples of both homogeneous and heterogeneous lattice structures.

Heterogenous Lattice Structures

Heterogeneous lattices are useful because we can tailor the properties of the lattice in specific regions of the part. For example, the density of the lattice can be driven from a finite element analysis (FEA). In areas, where the part stress is higher, we can increase the density of the lattice and therefore increase the strength in that location.

Conformal Lattices

The final lattice descriptor that we will introduce in this post is a conformal lattice. Lattices can either be uniform in a design space or conform to the shape of the part. Conformal lattices can be set up to follow the contours of a part. This makes the lattice look more appealing, and more importantly, can reduce stress concentrations building up at the part’ boundaries.

TPMS structures have been created by using a cylindrical coordinate frame within a cubic structure. Manipulating the coordinate reference frame can create interesting shapes that can have interesting applications. In this case a heat sink.

To learn more about Altair’s additive manufacturing capabilities, click here.