New Altair SimSolid safety factor plots

Safety factors are used to characterize zones of possible material failure and are based on material specific failure criteria. Now available in the latest release of the Altair SimSolid Standard and Power editions, safety factors contour plots can be displayed for any structural analysis.

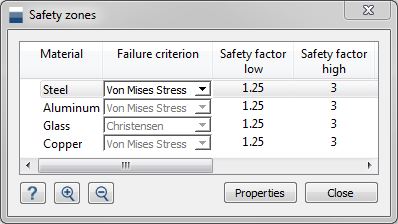

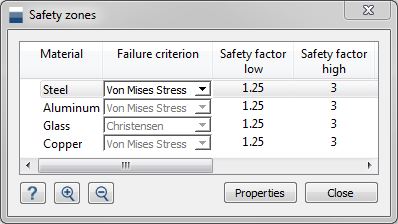

Safety zone contours are presented in 3 color bands (red, yellow and green). The threshold between bands are controlled by the Safety Factor Low and Safety Factor High values. The factors act as multipliers on the criterion value and reflect the degree of uncertainty that the user is looking to tolerate. For example, a safety factor value of 1.25 indicates a 25% safety margin on the failure criterion value.

Safety zone contours are presented in 3 color bands (red, yellow and green). The threshold between bands are controlled by the Safety Factor Low and Safety Factor High values. The factors act as multipliers on the criterion value and reflect the degree of uncertainty that the user is looking to tolerate. For example, a safety factor value of 1.25 indicates a 25% safety margin on the failure criterion value.

To view the safety zone contour plot, simply select one or more material rows on the dialog. CTRL or SHIFT select to choose more than one row. For complex assemblies, the selected part can be easily located in the assembly using auto-zoom in/out buttons (the plus and minus magnifier icons located at the bottom of the dialog).

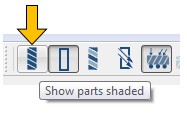

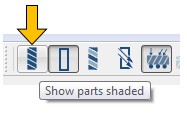

Notice that the rest of the model is displayed in wire-frame. If you prefer to see contours on all materials at one, select the Show part shaded button on the main toolbar.

All dialog values (Failure Criterion, Safety Factor Low, Safety Factor High, Tensile Yield Strength and Compressive Yield Strength) can be adjusted by the user. Contour plots will update on-the-fly as each adjustment is made. To see the Tensile Yield Strength and Compressive Yield Strength values, simply scroll the columns using the horizontal slider on the dialog. To see the database default material property values, select the Properties button.

All dialog values (Failure Criterion, Safety Factor Low, Safety Factor High, Tensile Yield Strength and Compressive Yield Strength) can be adjusted by the user. Contour plots will update on-the-fly as each adjustment is made. To see the Tensile Yield Strength and Compressive Yield Strength values, simply scroll the columns using the horizontal slider on the dialog. To see the database default material property values, select the Properties button.

We hope you like the new safety zone capability. Please let us know any areas that we can extend it further.

Using Altair SimSolid safety zones

The display of failure criterion plots can be invoked by selecting the Safety Zones button in the results area of the structural workbench toolbar. This opens the new safety zones dialog which displays all model materials along with their default failure criterion. Safety zone contours are presented in 3 color bands (red, yellow and green). The threshold between bands are controlled by the Safety Factor Low and Safety Factor High values. The factors act as multipliers on the criterion value and reflect the degree of uncertainty that the user is looking to tolerate. For example, a safety factor value of 1.25 indicates a 25% safety margin on the failure criterion value.

Safety zone contours are presented in 3 color bands (red, yellow and green). The threshold between bands are controlled by the Safety Factor Low and Safety Factor High values. The factors act as multipliers on the criterion value and reflect the degree of uncertainty that the user is looking to tolerate. For example, a safety factor value of 1.25 indicates a 25% safety margin on the failure criterion value.To view the safety zone contour plot, simply select one or more material rows on the dialog. CTRL or SHIFT select to choose more than one row. For complex assemblies, the selected part can be easily located in the assembly using auto-zoom in/out buttons (the plus and minus magnifier icons located at the bottom of the dialog).

Notice that the rest of the model is displayed in wire-frame. If you prefer to see contours on all materials at one, select the Show part shaded button on the main toolbar.

All dialog values (Failure Criterion, Safety Factor Low, Safety Factor High, Tensile Yield Strength and Compressive Yield Strength) can be adjusted by the user. Contour plots will update on-the-fly as each adjustment is made. To see the Tensile Yield Strength and Compressive Yield Strength values, simply scroll the columns using the horizontal slider on the dialog. To see the database default material property values, select the Properties button.

All dialog values (Failure Criterion, Safety Factor Low, Safety Factor High, Tensile Yield Strength and Compressive Yield Strength) can be adjusted by the user. Contour plots will update on-the-fly as each adjustment is made. To see the Tensile Yield Strength and Compressive Yield Strength values, simply scroll the columns using the horizontal slider on the dialog. To see the database default material property values, select the Properties button.

Altair SimSolid failure criteria

The following four failure theories are implemented in Altair SimSolid:- Max von Mises Stress – Most appropriate for ductile materials, this theory is also known as the maximum distortion energy criterion, octahedral shear stress theory or Maxwell-Huber-Hencky-von Mises theory. It is computed as the ratio of the material’s tensile yield strength to the von Mises stress.

- Max Shear Stress – Most appropriate for ductile materials, this theory is also known as Tresca's or Guest's criterion. It states that yielding begins whenever the maximum shear stress in the model becomes equal to the maximum shear stress in a tension test specimen that has begun to yield.

- Max Normal Stress – Most appropriate for brittle materials, this theory is also known as Coulomb’s criterion. It is computed by examining the ratio of the material’s tensile and compressive strength to the max principal stresses.

- Christensen - this is a more recent theory that tries to bridge the gap between failure criteria for ductile and brittle materials. The Christensen failure criterion is composed of two separate subcriteria representing competitive failure mechanisms. One has a quadratic form similar to the von Mises criterion and the other is a Coordinated Fracture criterion similar to the Coulomb-Mohr criterion. Details on this theory can be found at the website www.FailureCriteria.com.

Additions to Altair SimSolid material database

The Altair SimSolid material database has been extended to support the new safety zones capability. We have added new material property entries for tensile and compressive yield strengths, ultimate tensile strength and default material failure criterion. In addition, many new material have been added.IMPORTANT NOTE: Since the material database has new added fields, you must delete your existing material database, prior to running this version of Altair SimSolid. Go to the directory C:UsersYOUR-USERNAMEAppDataRoamingSimsolid and remove all *.ssm files. Now when Altair SimSolid starts it will move the new sample database (with the added fields) into the same directory. An alternative is to keep your existing material database, but manually add in the new values given above on your own.

As always, these materials should be used as examples only. We recommend that you consult your supplier for more exact property specifications.We hope you like the new safety zone capability. Please let us know any areas that we can extend it further.