Automotive

The automotive industry is undergoing a rapid transformation that’s changing the way vehicles are designed, developed, produced, and sold. Altair is at the forefront of this digital transformation, delivering comprehensive expertise and support

across the entire product development lifecycle.

From design and engineering to manufacturing and supply chain management, Altair's cutting-edge technologies and solutions in e-propulsion, connectivity, electromagnetic compatibility

(EMC), and data analytics enable us to support the world’s largest OEMs and suppliers to accelerate product development, enhance advanced safety and user experience, optimize vehicle fuel economy and vehicle architectures, reduce time to market

and optimize costs, and improve sustainability.

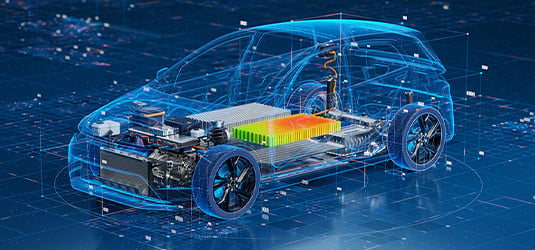

Digital Twin for Every Stage

Altair's digital twin solutions use simulation, machine learning, and artificial intelligence to create virtual representations of physical assets. This technology optimizes vehicle performance, reduces costs, and speeds up time-to-market. Real-time monitoring and analysis of vehicle data helps automakers identify and fix issues before they occur, improving reliability and reducing downtime. Altair's digital twin solutions reduce the need for physical testing, enabling automakers to simulate and test new designs and performance scenarios.

Accelerate Automotive Design with High-Performance Computing (HPC)

The best simulation tools won’t deliver what you need unless they’re supported by the right solutions to keep your high-performance computing infrastructure running optimally. Altair computing solutions give automotive designers and manufacturers faster times-to-market and superior product quality with a comprehensive set of workload management and optimization tools for clusters, supercomputers, and cloud.

Automotive’s Only Award Dedicated to Vehicle Lightweighting

The Body | Accelerate Design and Development

Streamlined Design Process

Altair's expertise in product development and data analytics enables clients to streamline the design process and reduce time to market. Our automotive software solutions, such as Altair® Inspire™ and Altair® HyperMesh®, provide engineers with tools to optimize product design, increase collaboration, and reduce physical prototyping. With our solutions, automakers can quickly and efficiently design and develop high-quality products.

Cost-Effective Prototyping

Altair's solutions in e-propulsion, such as model-based development (MBD), help clients reduce costs and improve efficiency by simulating product performance in a virtual environment. This creates a more efficient prototype development process, and ultimately, a faster time to market.

Optimize Your Manufacturing Process

Efficient manufacturing processes are vital for success. However, traditional methods are expensive, time-consuming, and error-prone. Altair's solutions for process simulation, additive manufacturing, and tooling design help automakers optimize processes, increase efficiency, and reduce costs. Our predictive analytics solutions can identify low-quality products early, thereby eliminating waste, ensuring high-quality outputs, and reducing energy usage.

Efficient Platform Design

Altair’s solutions in automotive vehicle development, such as multi-disciplinary optimization (MDO), are designed to optimize “skateboard” platform designs for a wide range of use cases (including BEV, HEV, PHEV), as well as functions (sedan, truck, adventure) to improve performance and reduce development costs.

Discover the future: Explore megacasting and AI-powered generative design.

Learn MoreThe Heart | Enhance Electric Vehicle Propulsion

Accelerating E-Motor Design and Development

The shift towards electric propulsion demands efficient, quiet, and lightweight motors, while reducing cabin noise and vibration. Altair provides an end-to-end solution for designing and developing electric motors, offering fast concept evaluation, detailed analysis of electromagnetic and thermal phenomena, automated design exploration, drive cycle simulation, and powertrain component optimization.

Achieving Optimal Motor, Inverter, and Battery Interactions

Ensuring safe, efficient inverter-motor interactions is a crucial challenge in electric vehicle design. Altair provides an approach to develop exceptional power density systems while identifying EMI/EMC compatibility issues early. Complementary solutions ensure high-energy battery packs immune to thermal runaway, help reengineer vehicle structures for the load of the battery, and protect vehicle occupants and the battery during crashes by simulating crash scenarios.

Maximizing Electric Vehicle Range

Accurately calculating the energy balance and range of electric vehicles requires careful consideration of critical subsystems like the powertrain, vehicle aerodynamics, and battery pack. Altair's advanced holistic solutions use reduced order modeling to optimize these subsystems and achieve better EV designs without relying on high-fidelity simulation models.

Transforming Transmission Development

Engineers must create efficient, reliable, and high-performing transmissions all while minimizing road vibrations to ensure smooth vehicle operation and mitigate cabin sound. Altair provides advanced capabilities for modeling and simulating multi-body gearbox and powertrain systems, optimizing the cooling of traction motors, and maximizing the thermal optimization of gearbox and housing components.

Ready to shift your automotive innovation forward?

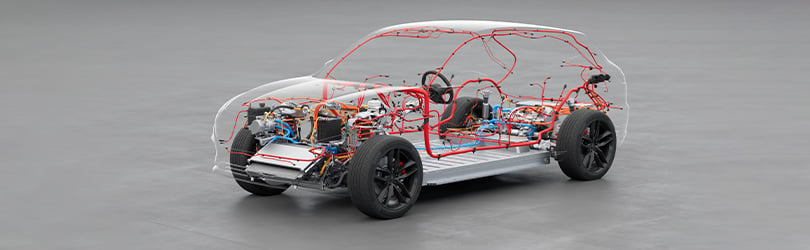

Contact UsThe Nervous System | Test Connectivity and Electromagnetic Compatibility

Simulate and Analyze Electromagnetic Behavior

Optimizing antenna design and placement, achieving EMC compliance, minimizing EMI, and testing Vehicle-to-Everything (V2X) or ADAS radars can be costly, complex challenges. Altair® Feko® offers antenna design and placement optimization, EMC analysis, EMI mitigation, and virtual test drives for installed antenna performance, V2X communication, and ADAS radar development. It also helps engineers simulate electromagnetic behavior in components like antennas and sensors for better communication and coordination between vehicle systems.

Smart Electronic System Visualization

Altair® EEvision™ is a smart electronic system visualization solution that simplifies the debugging process for complex automotive electrical systems. It provides real-time visualizations and up-to-date schematics for system connectivity, wiring harnesses, and component attributes, allowing users to identify signal paths and ensure system functionality.

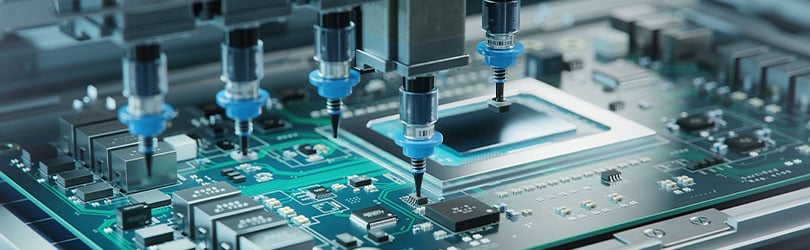

Optimize Electronic Boards in Connected Vehicles

Altair® PollEx™ offers a comprehensive solution for PCB verification, including design review, verification, and manufacturing assessment, complemented by Altair® SimLab®, which enables earlier issue identification together with thermal and mechanical analysis to optimize the performance and reliability of electronics in smart and connected vehicles.

Unlock the Full Potential of Your Connected Vehicle Data

Analyzing connected vehicle data in real-time is complex and resource-intensive, which limits companies’ ability to enhance vehicle performance, safety, and reliability. Altair® IoT Studio™ empowers companies to extract and analyze valuable insights from their connected vehicle data.

The Blood | Analyze Vehicle and Business Performance

Enhance Supply Chain Management

Inefficiencies, delays, and higher costs are just some of the challenges the automotive supply chain faces today. Altair understands these challenges and complexities, and provides comprehensive supply chain management solutions to optimize sourcing, inventory, and logistics. Our tools, including supplier collaboration, demand planning, and logistics optimization, help customers achieve greater efficiency and cost savings.

With Altair’s data analytics and supply chain optimization expertise, automakers can master variable demand and streamline their operations, ensuring they can deliver high-quality products to their customers on time and within budget.

Plan Maintenance and Prevent Equipment Failure

Conducting preventative maintenance, according to use time and cycles, helps automakers avoid equipment failure. But it can also mean stopping a well-functioning machine, even if there’s nothing currently wrong. Predictive maintenance is a better

way organizations can maintain equipment without disrupting production.

By pairing our intuitive machine learning tools with cloud-based or edge computing systems to analyze data from your factory floor, Altair® RapidMiner® helps you keep a close eye on your equipment’s health. Our solutions give you the confidence to keep machines running, knowing that you can catch and address issues that aren’t easily detectable, avoiding costly failures and equipment

downtime.

Transform the Warranty Process

The large number and variety of warranty claims in the automotive market makes traditional business intelligence-based methods unwieldy. But these claims contain valuable information about product quality and reliability, customer expectations, and can reveal design or manufacturing defects. Our solutions enable automakers to utilize this data source make improvements to existing products, develop more reliable new products, and drive increased profitability.

Featured Resources

Fully automated in a single process: Optimization and manufacturing of CFRP components

Use of HyperWorks and adapted three-step optimization process for Composite materials integrated in the production process.

Benefits:

- process suitable for large volume series

- flexibility in production

- short learning curve for users

- light and yet stiff components

Renault Nissan Mitsubishi Alliance Uses Altair SimSolid to Bring Vehicles Chassis Faster onto the Road

Renault Nissan Mitsubishi Alliance is a French-Japanese strategic partnership between the automobile manufacturers Renault (based in France), Nissan (based in Japan) and Mitsubishi Motors (based in Japan). Today, the automotive group has 122 manufacturing plants worldwide with nearly 450,000 employees controlling ten major brands: Renault, Nissan, Mitsubishi, Infiniti, Renault Samsung, Dacia, Alpine, Datsun, Venucia, and Lada. The ambition of the alliance is to offer autonomous drive, connectivity features, and services on a wide range of affordable vehicles. As part of the Renault Chassis Le Mans plant, which is building car-to-ground connecting components for the Renault Group and for the Alliance, the CTC Chassis Technical Center is a CAD engineering center where 350 engineers and technicians are working with a focus on testing and validation. Renault has been using SimSolid to perform simulations to develop lighter chassis faster.

View From Industry: Simulation Driving Efficiency and Innovation at Jaguar Land Rover

In this presentation hear about some of the latest innovations at Jaguar Land Rover and their 'Reimagine' Strategy that includes electrification technologies and connected services. Key technology developments are mentioned, including JLR's unique multi-disciplinary organization and the importance of simulation. The role of academia and how it can support industry is discussed, alongside a look at the ideal engineer profile and skill sets required.

Presented at the 2nd Altair Academic Outreach Event in June 2021

Speaker: Dr. Tayeb Zeguer, Group Tech Leader, Advanced CAE, Jaguar Land Rover

Duration: 15 minutes

How Litens Automotive Powered Their Simulation-driven Design Journey with HPC

Dr. Gianmarc Coppola, Engineering Manager at Litens, explains how Litens engineers leveraged the Altair Unlimited Physical appliance, a turnkey, fully managed HPC cluster, and its impact on their design/development processes, simulation throughput and overall competitiveness.