Lattice Structures

Complex lattice structures are revolutionizing the way we think about high-performance components. By engineering mechanical properties to give them exceptional strength-to-weight ratios, low density, and incredible energy absorption capabilities, lattice structures are paving the way for more sustainable outcomes in manufacturing and beyond.

For the creation and manufacture of optimized lattice structures, Altair offers versatile, robust design solutions employing advanced implicit modeling technologies and generative design capabilities. Using our cutting-edge lattice generation tools and simulation capabilities, users can achieve lighter, stronger, and more sustainable parts. Our complete design for manufacturing solution takes additive manufacturing to the next level.

Altair® Inspire™

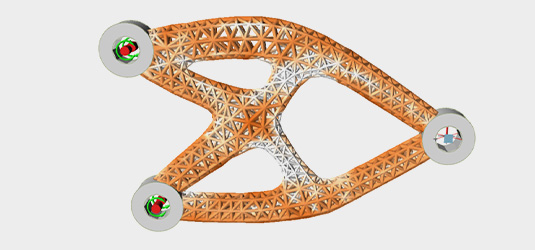

Within Inspire, Altair’s comprehensive design for manufacturing (DfM) solution, design engineers can easily explore the benefits of engineering with lattice structures early in the design process. With a one-click lattice creation feature, leveraging advanced implicit modeling technology, engineers can quickly generate intricate lattice structures, fine-tune their properties and performance, then evaluate their additive manufacturing feasibility.

Altair® Sulis™

Sulis is a legacy additive manufacturing solution for lattice structures. With its implicit modeling now enhanced and integrated into Inspire, Sulis retains its niche for optimizing flow in complex fluid networks, routing, and interfacing components to be more compact and manufacturable with automated self-supporting fluid channels.

Altair® OptiStruct®

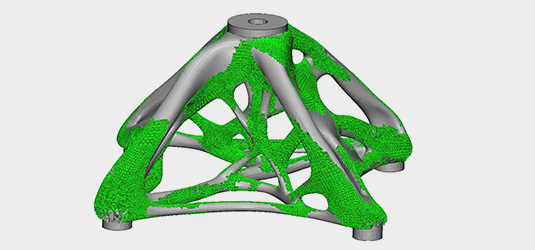

OptiStruct is a powerful finite element analysis solution that can design and optimize the performance of lattice structures in real-world applications, enabling designers to create optimized parts that meet even the most demanding requirements. With it, users can generate detailed reports on lattice structure performance, including stress, displacement, and strain information. Users can utilize this data to optimize designs further, ensuring that the final product is efficient and effective.

Begin designing components with lattice structures today

Try Now

Lattices and Additive Manufacturing

Lattice structures are on the rise due to additive manufacturing, which can produce intricate and precise shapes, leading to components with extended capabilities that are impossible to create via conventional manufacturing techniques. This manufacturing process allows precise control of the structure geometry, material properties, and part accuracy, which delivers optimized performance while reducing waste. Altair empowers designers to explore the limitless possibilities of lattice structures in conjunction with additive manufacturing, optimizing parts for lightweighting, energy absorption, thermal management, medical implants, and more.

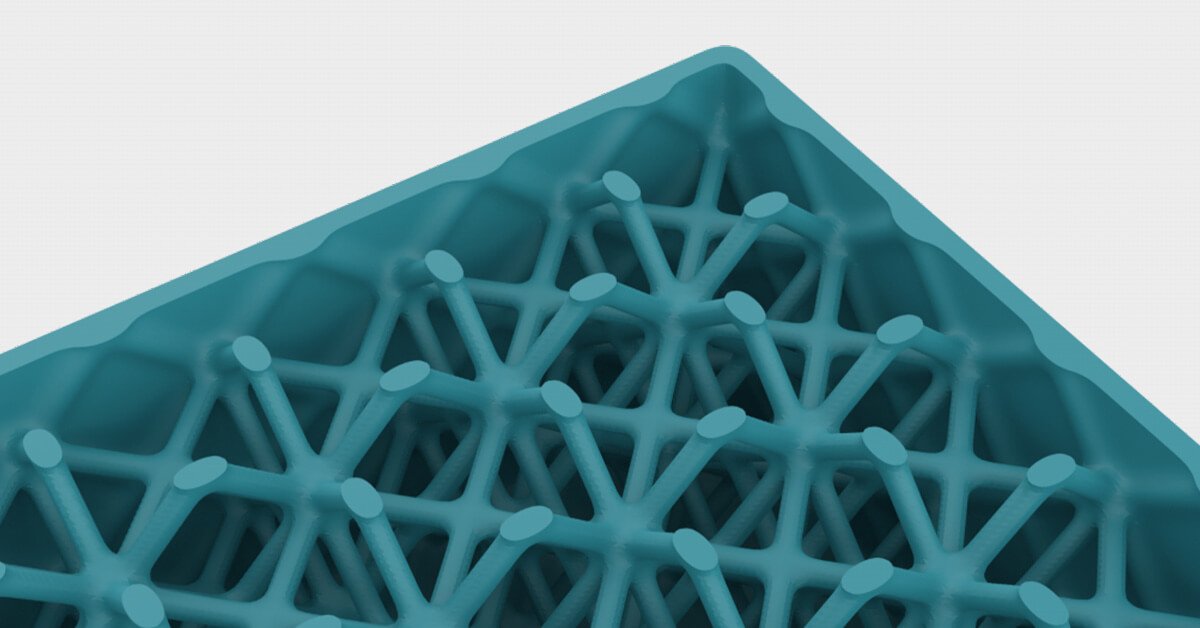

Lattice Generation by Implicit Technology

Implicit modeling describes surfaces as a field that generates incredible design flexibility, extraordinarily complex surfaces, and massive efficiency gains in editing and rendering shapes. Inspire’s lattice generation, using advanced implicit modeling technology, empowers designers to quickly generate and iterate on designs, delivering faster, more efficient product development to unlock the future of DfAM.

Sustainability

Replacing solid material with innovative lattice structures can reduce waste in manufacturing and impact energy requirements in usage and transport, reducing emissions and fuel consumption. Altair is opening new avenues for product design and engineering innovation with fast, efficient lattice structures and the associated technology of additive manufacturing to create a more sustainable future.

Bespoke Performance

Lattices exhibit anisotropic properties, stiffness, strength, toughness, and high thermal conductivity. They also resist deformation, distribute stresses and strains evenly, absorb energy without fracturing, and efficiently transmit vibrations and energy. Altair’s software solutions tailor and optimize lattice structure characteristics to meet any functionality requirement.

Explore Altair’s unparalleled design freedoms for additive manufacturing

Contact UsApplications of Lattice Structures

Lattice structures have many applications, from automotive and aerospace to medical implants and consumer goods.

- Lightweighting: One of the most significant benefits of lattice structures is their ability to lighten objects’ weight while maintaining structural integrity. Lightweighting has become crucial in many industries because lightweight objects consume less energy and are more cost-effective and sustainable.

- Energy absorption: Lattice structures' exceptional energy absorption properties are another critical benefit. This makes them ideal for impact-absorbing materials like helmets and body armor; lattices help distribute the energy of an impact more evenly, reducing serious injury risk in these types of products. Lattices can also be used for vibration dampening and noise absorption in various applications.

- Thermal management: Lattice structures are also incredibly effective at managing heat. Their unique design creates a large surface area for heat dissipation, making them ideal for thermal management applications, such as heat exchangers.

- Osseointegration: In the medical field, lattice structures are used to create customized patient implants to fit the exact shape and size of a patient's unique anatomy, improving the success rate of surgeries and shortening recovery times. Lattices’ porous structure also allows for the integration of cells and tissues, promoting bone and tissue growth that hastens the healing process.

Featured Resources

Types of Lattices for Additive Manufacturing – Terms Engineers Need to Know

One of the advantages of additive manufacturing (AM) is the ability to create fine-featured high-precision shapes, and many designers have taken advantage of this and added lattice or cellular structures to their components. These structures can extend the capabilities of the part beyond what’s possible using traditional manufacturing methods. Let’s explain the terminology AM engineers use when referring to lattice structures.

Beyond Lightweighting – The Benefits of 3D-Printed Metamaterials

Multi-functional lattice structures utilizing metamaterials have the potential to radically change the future of products that we use in our daily lives and the way in which industries like aerospace and the medical field operate. There are many benefits to 3D-printed metamaterials that go way beyond common design for additive manufacturing (AM) techniques. Let’s look at the benefits of this innovative geometric design phenomenon.

Exploring Modern Soccer Cleat Design with Altair Sulis

Finding ways to optimize players’ footwear so it’s lightweight yet durable and practical helps players stay quick on their feet and deliver game-winning results. We’re big soccer fans at Altair, so we wanted to try our hand at developing our own soccer cleat that could compete with the modern designs we’ll see in this year’s World Cup and beyond. Naturally, we turned to our suite of simulation tools to get to work.

Using Additive Manufacturing to Quicken the Transition to Net Zero

As our world transitions to renewable energy, making an unpredictable energy source reliable proves to be a challenge. One solution is storage technology; however, being able to scale this up provides its own challenges. Exergy Solutions has found solutions to these challenges through lab and pilot plant iterations and the use of advanced generative design software, additive manufacturing, and agile engineering. This has helped our client prove their technology and quicken the time to scale up this game-changing technology.