Featured Client: Motorsport: Roll Cages Optimized by Bremar Automotion using RADIOSS

Australia. The name immediately evokes vivid images of the vast outback, the iconic Sydney Opera House, the exotic Great Barrier Reef, aboriginal art, kangaroos, koalas and shudder….even crocodiles and snakes. Surrounded by the Indian and Pacific Oceans, Australia is a unique and culturally diverse haven for tourists. With a climate that is mostly temperate across the country, it’s broad, multiracial culture, as varied as its landscape, is reflected in its lifestyle, food, practices and sports.

Motorsport is a highly popular spectator sport in Australia, ranking among the top 5 most attended sports in the country. Formula One (F1), the oldest motorsport in the world, is also the oldest in Australia with the F1 Australian Grand Prix being the most popular with attendance of over 300,000 spectators as well as media coverage viewership exceeding a million.

The excitement at any motorsport event is tangible; the sights, sounds and smells promising a thrilling experience for both spectators as well as participants. However, as is the case with any sport involving racing of motor vehicles, along with the excitement ensues elements of high risk and danger which must be mitigated by following established safety precautions and standards set by The Federation Internationale de’l Automobile (FIA) and Confederation of Australian Motor Sport (CAMS). Participating vehicles are therefore equipped with Roll Over Protection Structures (ROPS) such as roll cages, designed to protect the motorists from injuries caused by vehicle overturns or rollovers during an accident.

Based in Melbourne, Australia, Bremar Automotion is an engineering design company specializing in simulation, testing, validation, and optimization of designs using Computer Aided Engineering (CAE) across a range of industries such as automotive, truck & trailer, mining, industrial equipment and motorsport. Bremar Automotion was recently granted approval from CAMS and the FIA to certify motorsport roll cages using Finite Element Analysis (FEA). This prestigious certification, granted only to approved bodies that are on the FIA’s technical list No. 35, enables Bremar to independently homologate motorsport roll cages using FEA both in Australia and internationally.

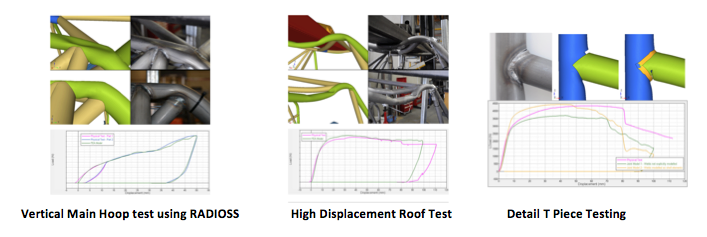

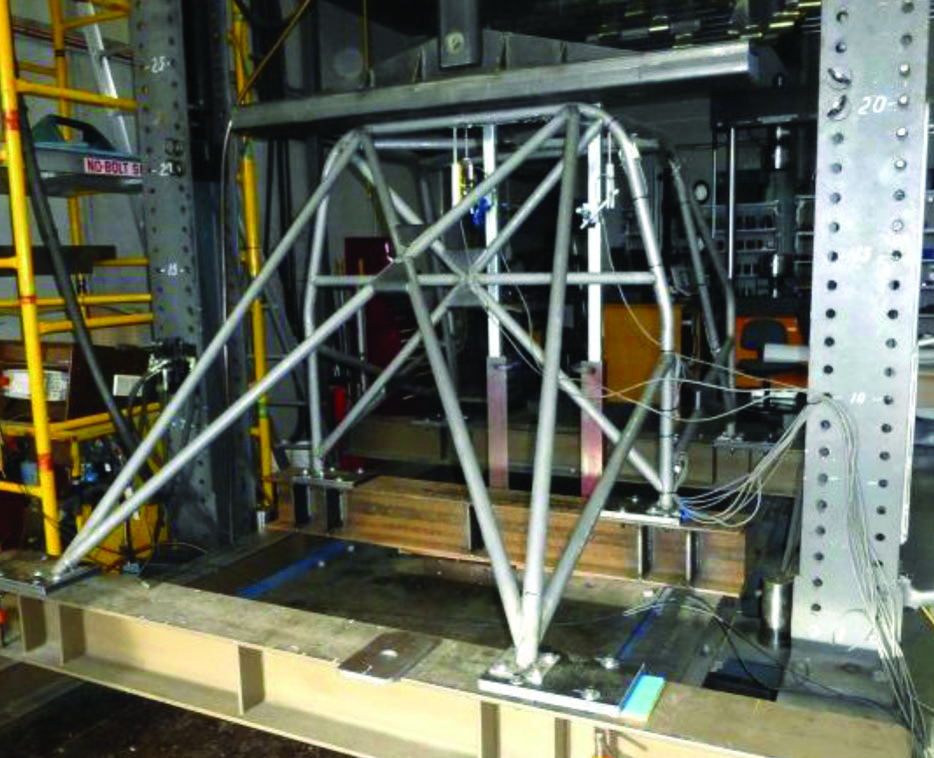

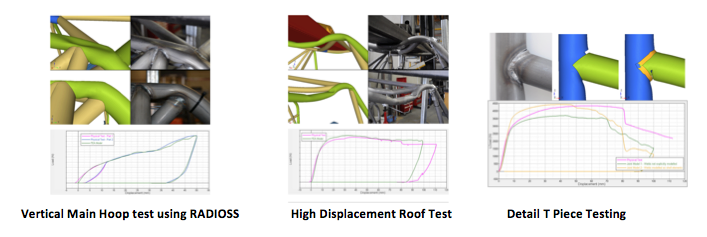

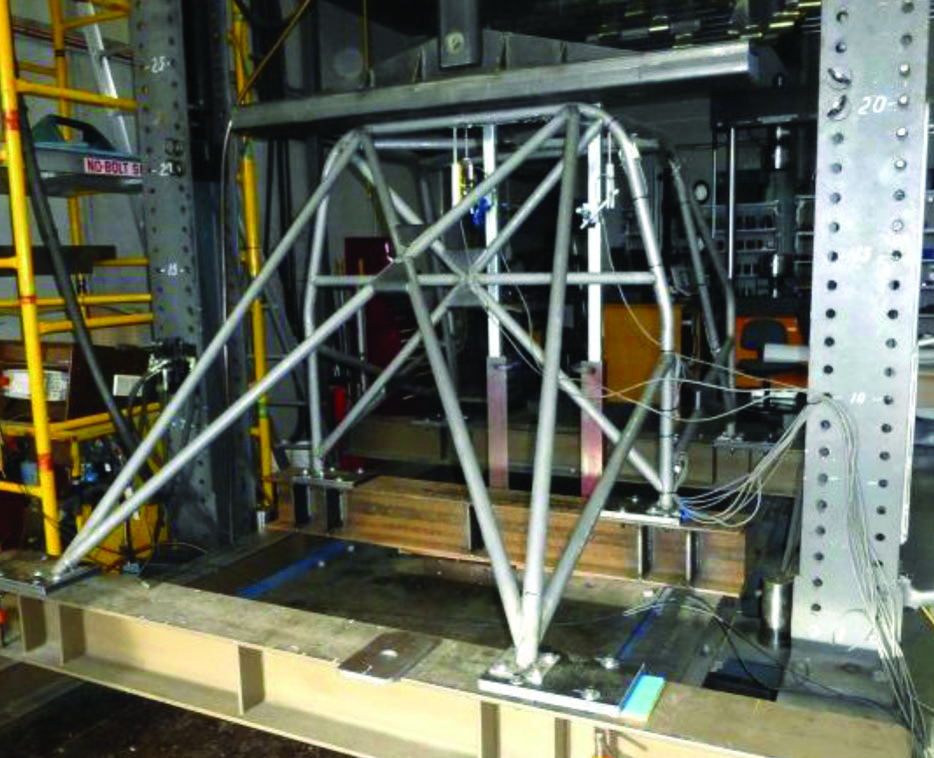

They began by designing a mild steel roll cage to suit the test rig based on FIA Load criteria. The roll cage was instrumented with multiple sensors and strain gauges in order to measure deflection and strain at various locations on the structure and allow correlation with the FEA model. The results from the physical test (FIA Load testing – Main Roll Hoop Test) compared with the FEA results using RADIOSS demonstrated the close correlation between the physical test and the computer model. An additional test was performed on the full cage (High Displacement Roof Test) to observe what happens at very high levels of displacement by moving the stamp applying the load forward onto the unsupported roof section and loaded to the travel limit of the test machine. Although simulating this level of loading and deflection was quite complex due to the highly nonlinear behavior, once again the FEA results compared exceptionally well to the physical test.

Since the roll cage structure is effectively made up of welded tube joints, for the final test (Joint Tests - Detail T Piece Testing), a set of six separate tests was performed to understand behavior around the welded joints with the intent of comparing the strength and performance of the different tube sizes and materials. Various sizes of mild steel and chromium-molybdenum steel (commonly known as chromoly) welded T pieces were tested and the FEA models of the welded regions were fine-tuned for good correlation. This was an invaluable part of the test schedule because it provided critical insights into how to model failure of these welded joints both accurately and conservatively.

“We did a range of extra tests that were not required for the FIA approval process. These additional tests were done to get as much deformation out of the structures as we could. We were interested in correlating our models in the high deformation, high nonlinear regions, so we basically pushed it as far as the test equipment would allow. In most cases, the correlation continued to stay very close over the whole range of displacement,” said Brett Longhurst, Managing Director at Bremar Automotion, “The Altair product is it for us in terms of simulation. That’s all we use. It’s great to be able to show such good correlation between the simulations and physical testing, and to have confidence in not only our approach, but also the Altair product as well. It’s a great product for us to be using, and the test results and these images just back that up for us.” he concluded.

“We did a range of extra tests that were not required for the FIA approval process. These additional tests were done to get as much deformation out of the structures as we could. We were interested in correlating our models in the high deformation, high nonlinear regions, so we basically pushed it as far as the test equipment would allow. In most cases, the correlation continued to stay very close over the whole range of displacement,” said Brett Longhurst, Managing Director at Bremar Automotion, “The Altair product is it for us in terms of simulation. That’s all we use. It’s great to be able to show such good correlation between the simulations and physical testing, and to have confidence in not only our approach, but also the Altair product as well. It’s a great product for us to be using, and the test results and these images just back that up for us.” he concluded.

Due to the inherently dangerous nature of motor racing, especially in the earlier years of racing, there have been many tragic fatalities involving both the car drivers as well as spectators. However, in recent years, advances in technology of safety devices, well-engineered roll cages, properly fitted by experts, as well as strict racing standards and speed limitations imposed by governing bodies have been instrumental in reduced fatalities. Not only can motorsport remain as one of the most popular spectator sports in Australia, but also continue to become safer without compromising on performance.

Download the complete Bremar Automotion success story

Motorsport is a highly popular spectator sport in Australia, ranking among the top 5 most attended sports in the country. Formula One (F1), the oldest motorsport in the world, is also the oldest in Australia with the F1 Australian Grand Prix being the most popular with attendance of over 300,000 spectators as well as media coverage viewership exceeding a million.

The excitement at any motorsport event is tangible; the sights, sounds and smells promising a thrilling experience for both spectators as well as participants. However, as is the case with any sport involving racing of motor vehicles, along with the excitement ensues elements of high risk and danger which must be mitigated by following established safety precautions and standards set by The Federation Internationale de’l Automobile (FIA) and Confederation of Australian Motor Sport (CAMS). Participating vehicles are therefore equipped with Roll Over Protection Structures (ROPS) such as roll cages, designed to protect the motorists from injuries caused by vehicle overturns or rollovers during an accident.

Based in Melbourne, Australia, Bremar Automotion is an engineering design company specializing in simulation, testing, validation, and optimization of designs using Computer Aided Engineering (CAE) across a range of industries such as automotive, truck & trailer, mining, industrial equipment and motorsport. Bremar Automotion was recently granted approval from CAMS and the FIA to certify motorsport roll cages using Finite Element Analysis (FEA). This prestigious certification, granted only to approved bodies that are on the FIA’s technical list No. 35, enables Bremar to independently homologate motorsport roll cages using FEA both in Australia and internationally.

Validation of a Roll Cage Virtual Model

As a requirement of their accreditation process, Bremar Automotion needed to construct and test a full size roll cage by applying the FIA’s specified roll cage loads to the structure. Destructive testing was required to confirm the accuracy of their computer modeling and to demonstrate competency to the FIA. The initial requirement was for a nonlinear, high-displacement and plastic deformation FEA analysis. Since Bremar engineers were already experienced users of Altair’s HyperWorks products, RADIOSS was the obvious choice for the nonlinear analysis requirements of this project.They began by designing a mild steel roll cage to suit the test rig based on FIA Load criteria. The roll cage was instrumented with multiple sensors and strain gauges in order to measure deflection and strain at various locations on the structure and allow correlation with the FEA model. The results from the physical test (FIA Load testing – Main Roll Hoop Test) compared with the FEA results using RADIOSS demonstrated the close correlation between the physical test and the computer model. An additional test was performed on the full cage (High Displacement Roof Test) to observe what happens at very high levels of displacement by moving the stamp applying the load forward onto the unsupported roof section and loaded to the travel limit of the test machine. Although simulating this level of loading and deflection was quite complex due to the highly nonlinear behavior, once again the FEA results compared exceptionally well to the physical test.

Correlation of results

Since the roll cage structure is effectively made up of welded tube joints, for the final test (Joint Tests - Detail T Piece Testing), a set of six separate tests was performed to understand behavior around the welded joints with the intent of comparing the strength and performance of the different tube sizes and materials. Various sizes of mild steel and chromium-molybdenum steel (commonly known as chromoly) welded T pieces were tested and the FEA models of the welded regions were fine-tuned for good correlation. This was an invaluable part of the test schedule because it provided critical insights into how to model failure of these welded joints both accurately and conservatively.

Accurate Prediction of Highly Nonlinear Deformations

To achieve a higher degree of confidence in their process, some of the tests performed on the motorsport roll cage were above and beyond those required for the FIA accreditation. Bremar’s test schedule also included a similar range of physical tests conducted on large Rollover Protection Systems (ROPS), as used on trucks, tractors and earthmoving machinery. Good correlation was achieved for these tests as well, again confirming the accuracy of Bremar’s simulation methods and the RADIOSS software. “We did a range of extra tests that were not required for the FIA approval process. These additional tests were done to get as much deformation out of the structures as we could. We were interested in correlating our models in the high deformation, high nonlinear regions, so we basically pushed it as far as the test equipment would allow. In most cases, the correlation continued to stay very close over the whole range of displacement,” said Brett Longhurst, Managing Director at Bremar Automotion, “The Altair product is it for us in terms of simulation. That’s all we use. It’s great to be able to show such good correlation between the simulations and physical testing, and to have confidence in not only our approach, but also the Altair product as well. It’s a great product for us to be using, and the test results and these images just back that up for us.” he concluded.

“We did a range of extra tests that were not required for the FIA approval process. These additional tests were done to get as much deformation out of the structures as we could. We were interested in correlating our models in the high deformation, high nonlinear regions, so we basically pushed it as far as the test equipment would allow. In most cases, the correlation continued to stay very close over the whole range of displacement,” said Brett Longhurst, Managing Director at Bremar Automotion, “The Altair product is it for us in terms of simulation. That’s all we use. It’s great to be able to show such good correlation between the simulations and physical testing, and to have confidence in not only our approach, but also the Altair product as well. It’s a great product for us to be using, and the test results and these images just back that up for us.” he concluded.Due to the inherently dangerous nature of motor racing, especially in the earlier years of racing, there have been many tragic fatalities involving both the car drivers as well as spectators. However, in recent years, advances in technology of safety devices, well-engineered roll cages, properly fitted by experts, as well as strict racing standards and speed limitations imposed by governing bodies have been instrumental in reduced fatalities. Not only can motorsport remain as one of the most popular spectator sports in Australia, but also continue to become safer without compromising on performance.

Download the complete Bremar Automotion success story